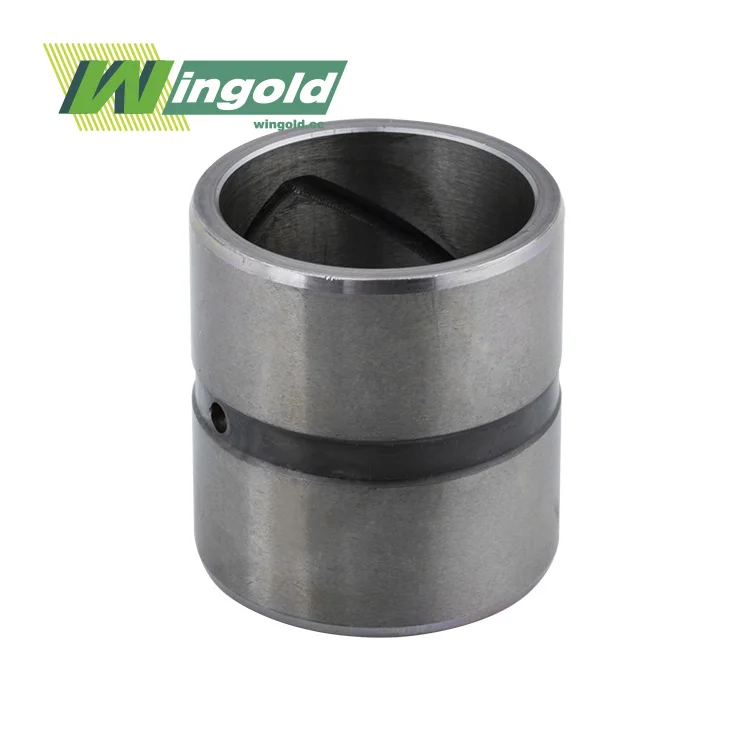

The Composition and Properties of CuPb10Sn10 Bimetallic Bushings

Material Composition and Its Impact on Wear Resistance

CuPb10Sn10 bimetallic bushings are meticulously engineered to provide exceptional performance in diverse industrial scenarios. The alloy's composition of 80% copper, 10% lead, and 10% tin is carefully calibrated to maximize wear resistance while maintaining other crucial properties.

Copper, the primary component, lends strength and thermal conductivity to the alloy. Its high thermal conductivity aids in dissipating heat generated during operation, which is crucial for maintaining the bushing's structural integrity and preventing premature wear.

Lead, comprising 10% of the alloy, plays a pivotal role in enhancing the self-lubricating properties of the bushing. As a soft metal, lead forms a thin film on the bearing surface during operation, reducing friction and wear. This self-lubricating characteristic is particularly beneficial in applications where continuous lubrication is challenging or impossible.

Tin, also at 10%, contributes to the overall hardness and wear resistance of the alloy. It forms intermetallic compounds with copper, enhancing the material's strength and durability. Additionally, tin improves the alloy's corrosion resistance, further contributing to the bushing's longevity in various operational environments.

Key Physical Properties Enhancing Wear Resistance

The CuPb10Sn10 bimetallic bushings boast several physical properties that directly contribute to their superior wear resistance:

- Hardness: With a hardness range of 60-75 HB (Brinell Hardness), these bushings strike an optimal balance between surface hardness for wear resistance and ductility for load distribution.

- Density: At 8.7 g/cm³, the material provides a robust structure capable of withstanding high loads and resisting deformation.

- Thermal Conductivity: The high thermal conductivity of 50 W/(m·K) ensures efficient heat dissipation, preventing localized hot spots that could lead to accelerated wear.

- Operating Temperature Range: With an impressive range from -40°C to 150°C, these bushings maintain their wear-resistant properties across a wide spectrum of operating conditions.

These properties synergize to create a bearing material that excels in wear resistance, making CuPb10Sn10 bimetallic bushings an ideal choice for applications demanding longevity and reliability.

Factors Influencing the Wear Resistance of CuPb10Sn10 Bimetallic Bushings

Load-Bearing Capacity and Its Relation to Wear

The superior load-bearing capacity of CuPb10Sn10 bimetallic bushings plays a crucial role in their wear resistance. The copper-based alloy provides exceptional strength, allowing these bushings to withstand high loads while maintaining their structural integrity. This high load-bearing capacity ensures that the bushing's surface remains stable under pressure, minimizing deformation and reducing wear.

When subjected to loads, the bimetallic structure of the bushing distributes the stress effectively. The steel backing provides rigidity and support, while the CuPb10Sn10 layer offers a wear-resistant surface. This combination allows for optimal load distribution, preventing localized stress concentrations that could lead to accelerated wear.

Moreover, the alloy's composition contributes to its load-bearing properties. The copper matrix provides strength, while the lead and tin components offer plasticity. This unique blend allows the bushing to adapt to minor misalignments or uneven loading without compromising its wear resistance.

Friction Coefficient and Heat Generation

The friction coefficient of CuPb10Sn10 bimetallic bushings is a critical factor in their wear resistance. These bushings are designed to operate with low friction, which directly translates to reduced wear over time. The self-lubricating properties of the lead component play a significant role in achieving this low friction coefficient.

During operation, the lead in the alloy forms a thin, lubricating film on the bushing's surface. This film acts as a barrier between the bushing and the mating surface, reducing direct metal-to-metal contact. As a result, the friction coefficient is substantially lowered, leading to smoother operation and less wear on both the bushing and the mating component.

The low friction coefficient also has a direct impact on heat generation. Lower friction means less energy is converted to heat during operation. This reduced heat generation is crucial for maintaining the bushing's wear resistance properties. Excessive heat can lead to thermal expansion, changes in material properties, and accelerated wear. By keeping heat generation to a minimum, CuPb10Sn10 bimetallic bushings maintain their dimensional stability and wear-resistant characteristics even under prolonged use.

Furthermore, the high thermal conductivity of the CuPb10Sn10 alloy (50 W/(m·K)) ensures that any heat generated is efficiently dissipated. This prevents the formation of hot spots that could lead to localized wear or material degradation. The ability to manage heat effectively contributes significantly to the overall wear resistance and longevity of these bushings.

Applications and Performance of CuPb10Sn10 Bimetallic Bushings in Various Industries

Automotive Industry Applications

In the automotive sector, CuPb10Sn10 bimetallic bushings have found widespread application due to their exceptional wear resistance and performance characteristics. These bushings are commonly used in various components of vehicle suspension systems, steering mechanisms, and powertrain assemblies.

In suspension systems, CuPb10Sn10 bimetallic bushings are often employed in control arm pivots, shock absorber mounts, and stabilizer bar connections. The bushings' ability to withstand high loads while maintaining low friction is crucial in these applications, ensuring smooth vehicle handling and ride comfort. Their wear resistance contributes to extended service life, reducing the frequency of maintenance and replacement.

For steering systems, these bushings are utilized in tie rod ends, steering column joints, and rack and pinion assemblies. The low friction coefficient of CuPb10Sn10 bimetallic bushings ensures responsive steering while their wear resistance maintains steering precision over time. This is particularly important for safety and driver comfort in modern vehicles.

In powertrain applications, CuPb10Sn10 bimetallic bushings find use in transmission components, alternator bearings, and starter motor bushings. Their ability to operate reliably under high loads and speeds, coupled with their self-lubricating properties, makes them ideal for these demanding applications where continuous lubrication may be challenging.

Heavy Machinery and Industrial Equipment

The wear resistance of CuPb10Sn10 bimetallic bushings makes them invaluable in heavy machinery and industrial equipment where operating conditions are often extreme. These bushings are widely used in construction equipment, agricultural machinery, and manufacturing plants.

In construction equipment such as excavators, bulldozers, and cranes, CuPb10Sn10 bimetallic bushings are used in pivot points, hydraulic cylinder mounts, and boom assemblies. Their high load-bearing capacity and wear resistance ensure reliable operation even under the harsh conditions typical of construction sites.

Agricultural machinery, including tractors, harvesters, and irrigation systems, also benefit from these bushings. The ability of CuPb10Sn10 bimetallic bushings to withstand exposure to dust, moisture, and varying temperatures while maintaining their wear-resistant properties makes them ideal for the demanding agricultural environment.

In manufacturing plants, these bushings are employed in conveyor systems, robotic arms, and various types of processing equipment. Their low friction characteristics contribute to energy efficiency, while their wear resistance ensures minimal downtime for maintenance or replacement.

The performance of CuPb10Sn10 bimetallic bushings in these diverse applications underscores their versatility and reliability. Their ability to maintain wear resistance under varying loads, speeds, and environmental conditions makes them a preferred choice across multiple industries. By providing extended service life and reduced maintenance requirements, these bushings contribute significantly to operational efficiency and cost-effectiveness in industrial applications.

Conclusion

CuPb10Sn10 bimetallic bushings stand out as a superior choice for applications demanding high wear resistance and reliable performance. Their unique composition, combining the strength of copper with the self-lubricating properties of lead and tin, results in bearings that excel in diverse industrial environments. From automotive components to heavy machinery, these bushings consistently demonstrate their ability to withstand harsh conditions while maintaining optimal functionality.

The exceptional wear resistance of CuPb10Sn10 bimetallic bushings translates to extended service life, reduced maintenance requirements, and improved operational efficiency across various industries. As machinery continues to evolve and demand higher performance, these bushings are well-positioned to meet the challenges of modern industrial applications. For more information on how CuPb10Sn10 bimetallic bushings can benefit your specific application or to discuss custom solutions, please contact Wingold Bearing at info@wingold.cc.

FAQ

What makes CuPb10Sn10 bimetallic bushings superior in wear resistance?

Their unique composition of 80% copper, 10% lead, and 10% tin provides an optimal balance of strength, self-lubrication, and durability, resulting in exceptional wear resistance.

Can CuPb10Sn10 bimetallic bushings operate in high-temperature environments?

Yes, these bushings can function effectively in temperatures ranging from -40°C to 150°C, making them suitable for various industrial applications.

Are CuPb10Sn10 bimetallic bushings environmentally friendly?

While they contain lead, their long service life and reduced need for external lubrication can contribute to overall environmental benefits in terms of resource conservation and reduced waste.