Introducing the Composition and Properties of Bronze and Brass Bushings

To fully appreciate why bronze is often the superior choice for bushings, it's essential to delve into the composition and properties of both bronze and brass. Bronze is primarily an alloy of copper and tin, while brass is an alloy of copper and zinc. This fundamental difference in composition leads to distinct characteristics that influence their performance as bushing materials.

Composition of Bronze Bushing Sleeves

Bronze bushing sleeves are typically made from high-quality bronze alloys such as C86300, C93200, or C95400. These alloys are carefully formulated to provide optimal performance in various industrial applications. The addition of tin to copper in bronze alloys results in a material with enhanced hardness, strength, and wear resistance compared to pure copper or brass.

Bronze bushings often incorporate other alloying elements like lead, nickel, or phosphorus to further improve specific properties. For instance, lead can enhance machinability and self-lubrication properties, while nickel can boost corrosion resistance and strength. This versatility in composition allows manufacturers to tailor bronze bushing sleeves to meet specific application requirements.

Properties of Bronze Bushings

Bronze bushing sleeves boast an impressive array of properties that make them ideal for demanding industrial environments:

High load-bearing capacity: Bronze bushings can withstand substantial loads without deforming or failing.

Excellent wear resistance: The hardness and strength of bronze contribute to its ability to resist wear and maintain dimensional stability over time.

Low friction coefficient: Bronze has natural lubricity, which helps reduce friction between moving parts.

Good thermal conductivity: Bronze efficiently dissipates heat, preventing overheating in high-speed or high-load applications.

Corrosion resistance: Bronze exhibits good resistance to many corrosive environments, including saltwater.

Self-lubricating properties: Some bronze alloys can form a thin film of lubricant on their surface, reducing the need for external lubrication.

Brass Bushing Characteristics

While brass bushings have their merits, they generally fall short of bronze in several key areas:

Lower strength and hardness: Brass is typically softer and less strong than bronze, limiting its use in high-load applications.

Reduced wear resistance: The softer nature of brass makes it more prone to wear and deformation under heavy loads or high-speed conditions.

Inferior corrosion resistance: Brass is more susceptible to certain types of corrosion, particularly dezincification in marine environments.

Lower melting point: Brass has a lower melting point than bronze, which can be a limitation in high-temperature applications.

Advantages of Bronze Bushing Sleeves in Industrial Applications

The unique properties of bronze bushing sleeves translate into numerous advantages in industrial settings. These benefits have made bronze the material of choice for a wide range of applications, from heavy machinery to precision instruments.

Enhanced Durability and Longevity

One of the primary advantages of bronze bushing sleeves is their exceptional durability. The high wear resistance and strength of bronze allow these bushings to maintain their dimensional stability and performance characteristics over extended periods, even under challenging conditions. This translates to longer service life and reduced maintenance requirements, ultimately lowering the total cost of ownership for equipment utilizing bronze bushings.

Superior Load-Bearing Capacity

Bronze bushing sleeves excel in high-load applications due to their impressive load-bearing capacity. This property is particularly valuable in heavy machinery, construction equipment, and industrial presses where bushings must withstand substantial forces without deforming or failing. The ability of bronze to distribute loads evenly also contributes to reduced wear and extended component life.

Excellent Thermal Management

The superior thermal conductivity of bronze bushing sleeves plays a crucial role in managing heat generated by friction or environmental factors. By efficiently dissipating heat, bronze bushings help prevent overheating and thermal expansion issues that can lead to premature wear or failure. This thermal management capability is especially beneficial in high-speed applications or environments with fluctuating temperatures.

Versatility in Design and Manufacturing

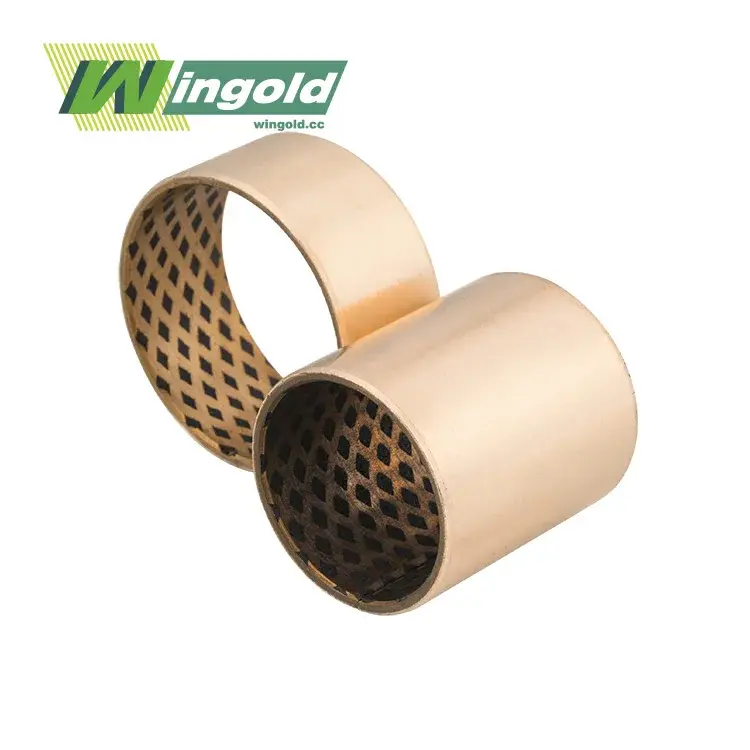

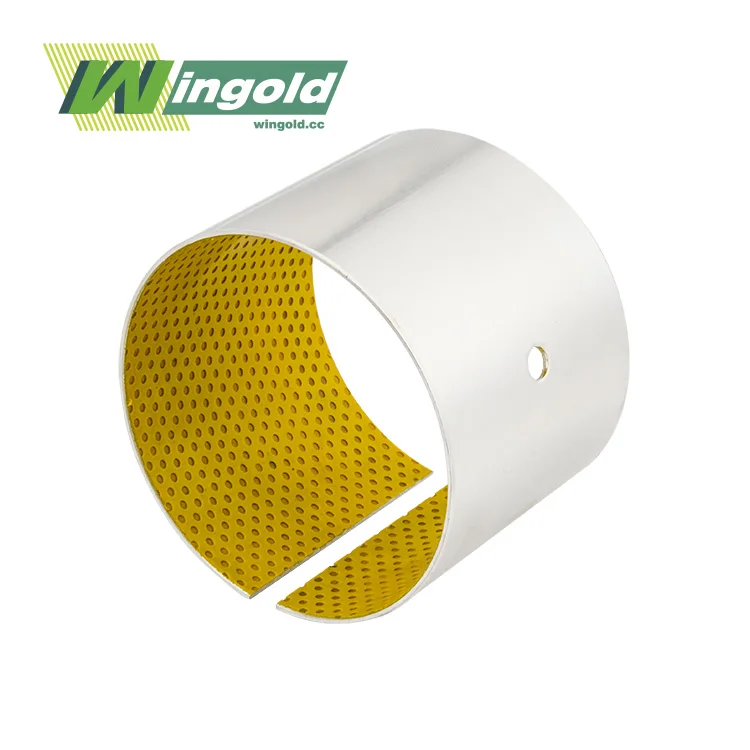

Bronze bushing sleeves offer great flexibility in design and manufacturing processes. They can be produced through various methods, including CNC machining, centrifugal casting, and powder metallurgy. This versatility allows for the creation of bushings with complex geometries, precise tolerances, and specialized features such as oil grooves or diamond-shaped indentations for improved lubrication retention.

Furthermore, bronze bushings can be engineered with specific surface finishes to optimize performance. For example, a surface roughness of Ra 0.8 - 3.2 μm can be achieved to balance friction reduction and lubricant retention. The ability to customize bronze bushing sleeves to meet exact specifications makes them suitable for a wide array of applications across different industries.

Selecting the Right Bronze Bushing Sleeve for Your Application

While bronze is generally superior to brass for bushings, choosing the right bronze bushing sleeve for a specific application requires careful consideration of several factors. Understanding these considerations can help ensure optimal performance and longevity of the bushing in its intended use.

Load and Speed Requirements

The load-bearing capacity and operating speed of the application are crucial factors in selecting the appropriate bronze bushing sleeve. Different bronze alloys offer varying levels of strength and wear resistance. For high-load, low-speed applications, alloys with higher lead content may be suitable due to their enhanced self-lubricating properties. Conversely, for high-speed operations, alloys with better thermal conductivity and hardness may be more appropriate.

Environmental Factors

The operating environment plays a significant role in bushing selection. Factors such as temperature, humidity, and exposure to corrosive substances should be considered. For applications in marine environments or those exposed to chemicals, bronze alloys with enhanced corrosion resistance, such as aluminum bronze or nickel-aluminum bronze, may be preferred.

Lubrication Considerations

The availability and type of lubrication in the application can influence the choice of bronze bushing sleeve. Some applications may require self-lubricating bronze alloys, while others may benefit from bushings designed with oil grooves or pockets to retain lubricant. The surface finish of the bushing can also be optimized to enhance lubrication effectiveness.

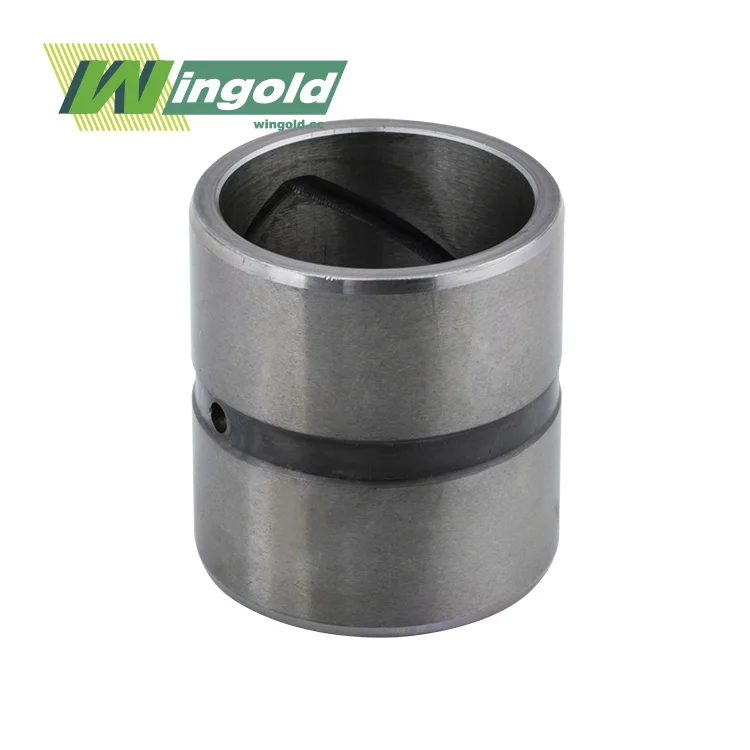

Size and Tolerance Requirements

Bronze bushing sleeves can be manufactured to precise dimensions and tolerances. Wingold offers bronze bushings with inner diameters ranging from 5mm to 500mm, outer diameters from 8mm to 600mm, and lengths from 10mm to 1000mm. The ability to meet tight tolerances according to ISO 2768 ensures proper fit and function in various applications.

Cost Considerations

While bronze bushings may have a higher initial cost compared to brass or some other materials, their superior performance and longevity often result in lower long-term costs. When evaluating costs, it's essential to consider factors such as expected service life, maintenance requirements, and the potential consequences of bushing failure.

Conclusion

In the debate of bronze versus brass for bushings, bronze emerges as the clear winner for most industrial applications. Bronze bushing sleeves offer superior strength, wear resistance, load-bearing capacity, and thermal management properties compared to their brass counterparts. The versatility of bronze alloys allows for customization to meet specific application requirements, making them suitable for a wide range of industries and operating conditions.

When selecting a bronze bushing sleeve, careful consideration of factors such as load requirements, operating environment, lubrication needs, and size specifications is essential to ensure optimal performance. By choosing the right bronze bushing for your application, you can benefit from extended equipment life, reduced maintenance, and improved operational efficiency.

For expert guidance on selecting the ideal bronze bushing sleeve for your specific needs, or to learn more about our customized bearing solutions, don't hesitate to contact Wingold Bearing at info@wingold.cc

. Our team of experienced engineers is ready to assist you in finding the perfect bushing solution to enhance your industrial operations.

FAQ

Can bronze bushings be used in high-temperature applications?

Yes, many bronze alloys maintain their strength and performance at elevated temperatures, making them suitable for high-temperature applications.

Are bronze bushings more expensive than brass bushings?

nitially, bronze bushings may have a higher cost, but their superior durability and performance often result in lower long-term expenses.

Can bronze bushings operate without lubrication?

Some bronze alloys have self-lubricating properties, allowing them to function with minimal or no external lubrication in certain applications.

What industries commonly use bronze bushing sleeves?

Bronze bushings are widely used in industries such as automotive, aerospace, marine, construction equipment, and industrial machinery.