Comprehending POM Coated Washers: Composition and Properties

The Unique Structure of POM Coated Washers

POM coated washers represent a pinnacle of engineering in the world of industrial components. These washers are meticulously crafted with a high-grade steel core, providing robust structural integrity. The steel core is then coated with polyoxymethylene (POM), a thermoplastic polymer renowned for its exceptional mechanical properties. This unique composition results in a washer that combines the strength of steel with the low-friction, self-lubricating properties of POM.

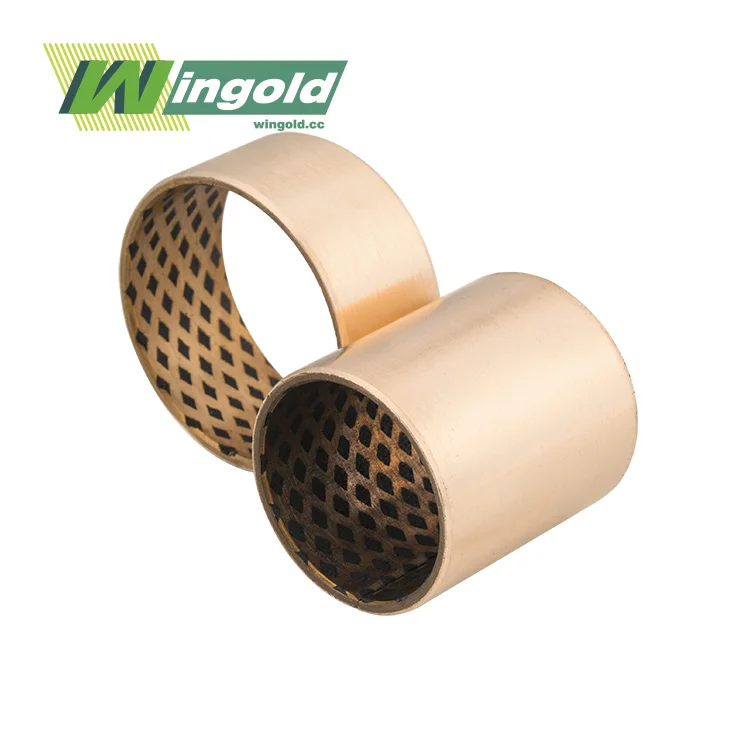

The structure of POM coated washers typically includes:

- A steel back for strength and durability

- A layer of sintered porous bronze powder for enhanced load-bearing capacity

- A top layer of modified polyformaldehyde (POM) for low friction and wear resistance

Some POM coated washers also feature oil indentations, which further enhance their self-lubricating properties. This sophisticated structure allows these washers to perform exceptionally well in a wide range of industrial applications.

Key Properties of POM Coated Washers

The unique composition of POM coated washers endows them with a set of remarkable properties that set them apart from standard washers:

- High load-bearing capacity: POM coated washers can withstand pressures up to 70N/mm²

- Low friction coefficient: These washers boast a friction coefficient (μ) ranging from 0.05 to 0.25

- Wide temperature range: They remain functional in temperatures from -40°C to 130°C

- Impressive PV value: The maximum allowable PV value (pressure x velocity) in dry conditions is 22N/mm²·m/s

- High sliding speed: These washers can handle sliding speeds up to 2.5m/s

These properties make POM coated washers highly versatile and capable of meeting the demands of various industrial applications, from automotive manufacturing to aerospace and heavy machinery.

Advantages of POM Coated Washers Over Standard Washers

Enhanced Durability and Longevity

One of the most significant advantages of POM coated washers over standard washers is their superior durability. The POM coating provides a protective layer that significantly reduces wear and tear, leading to a longer lifespan for the washer. This enhanced durability translates to fewer replacements, reduced maintenance costs, and less downtime for machinery and equipment.

Standard washers, typically made of metal or rubber, are more susceptible to wear, especially in high-friction or chemically harsh environments. In contrast, POM coated washers maintain their integrity and performance characteristics even under challenging conditions, making them a more reliable choice for long-term use.

Low Friction Performance

The POM coating on these specialized washers provides exceptionally low friction performance. This characteristic is crucial in many industrial applications where smooth operation and energy efficiency are paramount. The low friction coefficient of POM coated washers (0.05 to 0.25) significantly reduces energy loss due to friction, leading to more efficient machinery operation.

Standard washers, lacking this low-friction surface, can lead to increased wear on mating parts, higher energy consumption, and potentially more heat generation in operating machinery. The self-lubricating nature of POM coated washers further enhances their low-friction properties, reducing or eliminating the need for additional lubrication in many applications.

Chemical and Temperature Resistance

POM coated washers exhibit remarkable resistance to a wide range of chemicals, solvents, and fuels. This property makes them ideal for use in environments where exposure to harsh chemicals is common. Whether in chemical processing plants, automotive applications, or industrial cleaning processes, POM coated washers maintain their structural integrity and performance.

Moreover, these washers can operate effectively across a wide temperature range (-40°C to 130°C), making them suitable for applications that experience significant temperature fluctuations. Standard washers, particularly those made of rubber or certain metals, may degrade or lose their properties when exposed to extreme temperatures or corrosive chemicals.

Applications and Industries Benefiting from POM Coated Washers

Automotive Industry

The automotive industry has embraced POM coated washers for their exceptional performance in various vehicle components. These washers are commonly used in:

- Suspension systems: POM coated washers provide smooth operation and reduced noise in shock absorbers and struts

- Engine components: Their chemical resistance and durability make them ideal for use in fuel systems and engine mounts

- Transmission systems: The low friction properties of POM coated washers contribute to improved efficiency in gearboxes and clutch assemblies

The use of POM coated washers in these applications results in reduced wear, improved fuel efficiency, and enhanced overall vehicle performance.

Aerospace and Aviation

In the aerospace industry, where reliability and performance under extreme conditions are paramount, POM coated washers have found numerous applications:

- Aircraft landing gear: The high load-bearing capacity and low friction properties of these washers contribute to smoother operation and reduced maintenance needs

- Cockpit controls: POM coated washers provide precise, low-friction movement for various control mechanisms

- Fuselage components: Their resistance to temperature fluctuations and chemicals makes them suitable for use in various structural applications

The use of POM coated washers in aerospace applications contributes to weight reduction, improved fuel efficiency, and enhanced safety through reliable component performance.

Industrial Machinery and Equipment

POM coated washers have revolutionized various aspects of industrial machinery and equipment:

- Hydraulic and pneumatic systems: These washers provide excellent sealing and low friction in valves and actuators

- Conveyor systems: Their durability and low friction properties result in smoother operation and reduced maintenance in rollers and bearings

- Textile machinery: POM coated washers contribute to reduced wear and improved efficiency in high-speed spinning and weaving machines

- Food processing equipment: The chemical resistance and hygienic properties of POM make these washers ideal for use in food-grade machinery

By incorporating POM coated washers, industrial machinery benefits from extended component life, reduced downtime, and improved operational efficiency.

Conclusion

POM coated washers represent a significant advancement in washer technology, offering superior performance, durability, and versatility compared to standard washers. Their unique combination of a steel core and POM coating provides an optimal balance of strength, low friction, and chemical resistance. These properties make them an ideal choice for a wide range of industries, from automotive and aerospace to industrial machinery and equipment.

As industries continue to seek ways to improve efficiency, reduce maintenance costs, and enhance overall performance, the adoption of POM coated washers is likely to increase. Their ability to withstand harsh conditions, provide smooth operation, and extend component life makes them a valuable asset in modern industrial applications.

If you're looking to upgrade your machinery or equipment with high-performance components, consider POM coated washers. As a leading POM coated washer supplier and manufacturer, Wingold Bearing offers a wide range of customized solutions to meet your specific needs. For more information about our products and how they can benefit your operations, please contact us at info@wingold.cc.

FAQs

What makes POM coated washers different from standard washers?

POM coated washers feature a steel core with a polyoxymethylene (POM) coating, providing superior wear resistance, low friction, and chemical resistance compared to standard metal or rubber washers.

Can POM coated washers be used in high-temperature environments?

Yes, POM coated washers can operate effectively in temperatures ranging from -40°C to 130°C, making them suitable for many high-temperature applications.

Are POM coated washers more expensive than standard washers?

While the initial cost may be higher, POM coated washers often prove more cost-effective in the long run due to their extended lifespan and reduced maintenance requirements.