Understanding PTFE Coated Washers: Composition and Benefits

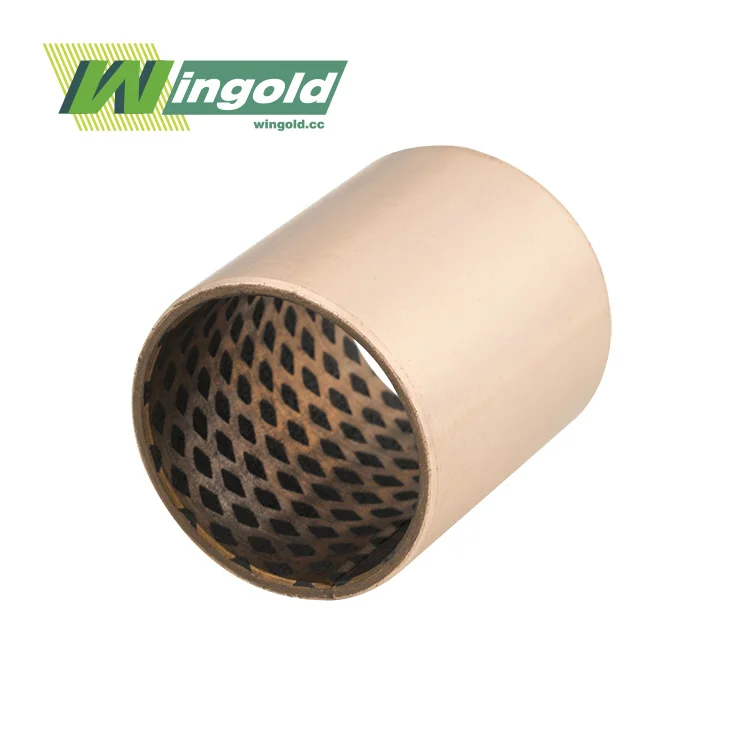

PTFE coated washers are engineered to provide optimal performance in challenging environments. These washers typically consist of a metal base, often stainless steel or bronze, coated with a thin layer of PTFE. This structure combines the strength and durability of metal with the unique properties of PTFE.

Composition of PTFE Coated Washers

The structure of PTFE coated washers is crucial to their performance. The metal base, usually stainless steel or bronze, provides the necessary strength and rigidity. This base is then coated with a layer of PTFE, typically ranging from 0.01 to 0.03 mm in thickness. This thin yet effective coating is what gives these washers their exceptional properties.

PTFE, known for its non-stick and low friction characteristics, forms a smooth, chemically inert surface on the washer. This surface is what interacts with the surrounding environment, providing protection to the metal substrate beneath.

Key Benefits of PTFE Coated Washers

The unique composition of PTFE coated washers offers numerous advantages, particularly in corrosive environments:

- Chemical Resistance: PTFE is renowned for its resistance to a wide range of chemicals, making these washers ideal for use in environments where exposure to corrosive substances is common.

- Low Friction: The PTFE coating significantly reduces friction, leading to smoother operation and less wear on mating components.

- Temperature Stability: These washers maintain their performance across a broad temperature range, typically from -200°C to +260°C, making them suitable for various industrial applications.

- Self-Lubrication: The inherent properties of PTFE provide self-lubrication, reducing or eliminating the need for additional lubricants.

- Durability: The combination of a strong metal substrate and a protective PTFE coating results in washers that can withstand harsh conditions for extended periods.

These benefits make PTFE coated washers an excellent choice for industries dealing with corrosive environments, such as chemical processing, oil and gas, marine applications, and food processing.

Selecting the Right PTFE Coated Washers for Your Application

Choosing the appropriate PTFE coated washers for your specific application requires careful consideration of several factors. Understanding these factors will help ensure that you select washers that will perform optimally in your particular corrosive environment.

Factors to Consider

When selecting PTFE coated washers, consider the following:

- Chemical Exposure: Identify the specific chemicals or corrosive substances present in your application. While PTFE is resistant to most chemicals, it's crucial to verify compatibility with your particular environment.

- Temperature Range: Determine the operating temperature range of your application. PTFE coated washers typically perform well from -200°C to +260°C, but it's essential to ensure this range meets your needs.

- Load Requirements: Consider the load the washers will need to bear. The metal substrate provides strength, but it's important to select washers with appropriate load-bearing capacities.

- Size and Dimensions: PTFE coated washers are available in various sizes, with inner diameters ranging from 3 to 150 mm and outer diameters from 6 to 200 mm. Choose washers that fit your application precisely.

- Thickness: Washer thickness can vary from 0.5 to 5 mm. Select a thickness that provides the necessary strength while fitting within your assembly constraints.

- Substrate Material: While stainless steel and bronze are common substrate materials, custom options may be available. Choose a substrate that complements the corrosion resistance of the PTFE coating.

Customization Options

For applications with unique requirements, customization may be necessary. Many manufacturers, including Wingold Bearing, offer customized PTFE coated washers. Customization options may include:

- Specific dimensions not available in standard sizes

- Custom substrate materials for specialized applications

- Varying PTFE coating thicknesses for different performance characteristics

- Color-coded PTFE coatings for easy identification

By carefully considering these factors and exploring customization options when necessary, you can select PTFE coated washers that will provide optimal performance and longevity in your corrosive environment.

Maintenance and Longevity of PTFE Coated Washers in Corrosive Environments

One of the key advantages of PTFE coated washers and PTFE composite bushings is their low maintenance requirements and long service life, even in corrosive environments. However, proper care and attention can further extend their lifespan and ensure optimal performance.

Maintenance Best Practices

While PTFE coated washers are largely maintenance-free, following these best practices can help maximize their performance and longevity:

- Regular Inspection: Periodically inspect the washers for signs of wear or damage. Look for any degradation of the PTFE coating or deformation of the washer.

- Cleaning: If necessary, clean the washers with a soft cloth and mild detergent. Avoid using abrasive materials or harsh chemicals that could damage the PTFE coating.

- Proper Installation: Ensure washers are installed correctly, with even pressure distribution. Overtightening can lead to deformation and reduced effectiveness.

- Temperature Monitoring: While PTFE coated washers have a wide temperature tolerance, consistently operating at the extremes of this range can accelerate wear. Monitor and control operating temperatures where possible.

- Chemical Exposure Control: Even with their excellent chemical resistance, minimizing unnecessary exposure to corrosive substances can prolong the life of PTFE coated washers.

Longevity and Replacement

PTFE coated washers are designed for extended service life, often outlasting traditional washers in corrosive environments. However, they are not immune to wear and will eventually need replacement. Factors affecting longevity include:

- The specific corrosive environment

- Operating temperatures

- Load conditions

- Frequency of use

Regular inspections can help determine when replacement is necessary. Signs that washers may need replacement include:

- Visible wear or thinning of the PTFE coating

- Deformation of the washer shape

- Increased friction or noise in the assembly

- Any signs of chemical attack on the washer

By implementing these maintenance practices and being attentive to the condition of your PTFE coated washers, you can ensure they continue to provide excellent performance and protection in corrosive environments for an extended period.

Conclusion

PTFE coated washers offer a superior solution for applications in corrosive environments. Their unique combination of a strong metal substrate and a chemically resistant PTFE coating provides exceptional performance, longevity, and reliability. By carefully selecting the right washers for your specific application and implementing proper maintenance practices, you can ensure optimal performance and extended service life.

If you're looking for high-quality PTFE coated washers for your corrosive environment applications, consider Wingold Bearing as your trusted supplier and manufacturer. With our expertise in material research, technological innovation, and production optimization, we offer superior PTFE plain bearing solutions that meet the most demanding industrial requirements. For more information or to discuss your specific needs, please contact us at info@wingold.cc.

FAQs

What makes PTFE coated washers suitable for corrosive environments?

PTFE coated washers combine a durable metal substrate with a chemically resistant PTFE coating, providing excellent protection against corrosive substances while maintaining strength and durability.

Can PTFE coated washers be used in high-temperature applications?

Yes, PTFE coated washers typically perform well in temperatures ranging from -200°C to +260°C, making them suitable for many high-temperature applications.

How often should PTFE coated washers be replaced?

The replacement frequency depends on the specific application and operating conditions. Regular inspections can help determine when replacement is necessary based on visible wear or performance changes.