Understanding Bronze Bushings and Their Importance

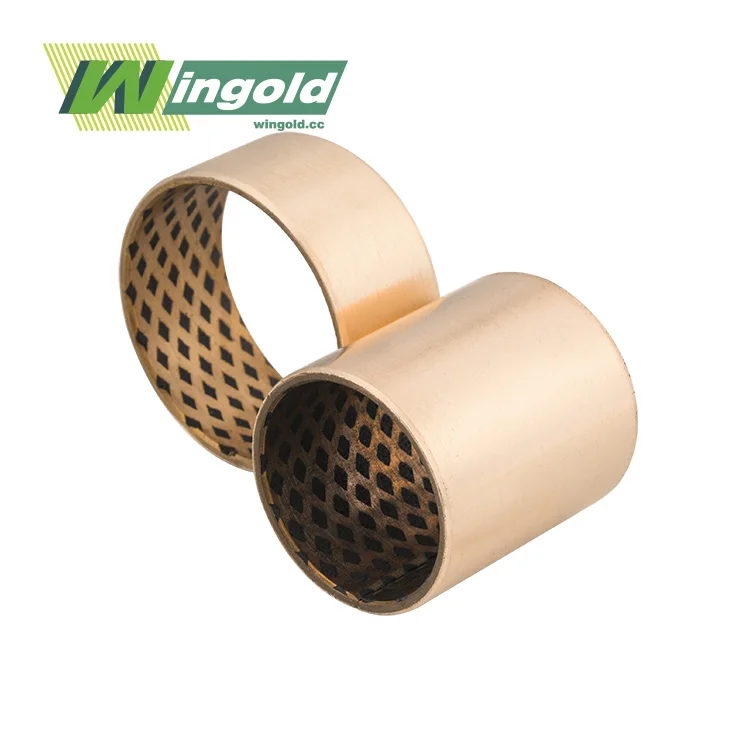

Bronze bushings play a crucial role in numerous mechanical systems across various industries. These cylindrical bearings, often made from copper alloys, provide a wear-resistant surface between a shaft and its housing. They reduce friction, distribute loads, and ensure smooth operation of moving parts.

932 bronze bushings, in particular, have gained popularity due to their exceptional performance characteristics. Made from SAE 932 bronze, these bushings offer a unique combination of strength, durability, and self-lubricating properties. This makes them ideal for applications requiring high load capacity and resistance to wear and corrosion.

Key Features of 932 Bronze Bushings

- High load-bearing capacity

- Excellent wear resistance

- Self-lubricating properties

- Corrosion resistance

- Wide temperature range tolerance

- Dimensional stability

Understanding these highlights is fundamental when considering 932 bronze bushings for your application, as fabric determination straightforwardly impacts framework unwavering quality and benefit life. SAE 932 bronze, too known as bearing bronze, is esteemed for its fabulous load-bearing capability, great machinability, and solid wear resistance beneath direct to overwhelming loads. Its adjusted composition permits it to perform well in applications including sliding movement, discontinuous grease, and shifting speeds.

These properties make 932 bronze bushings appropriate for a wide extend of requesting situations, counting car drivetrains, marine equipment, overwhelming mechanical apparatus, and indeed select aviation components. By coordinating the inalienable qualities of SAE 932 bronze to operational prerequisites, engineers and upkeep experts can optimize execution, decrease downtime, and accomplish long-term taken a toll proficiency over differing mechanical systems.

Signs It's Time to Replace Your Bronze Bushings

Recognizing when to replace your bronze bushings is crucial for maintaining optimal system performance and preventing costly breakdowns. Here are some telltale signs that indicate it might be time to consider replacing your bronze bushings:

Visible Wear and Tear

Visible wear and tear is frequently the most clear marker that bronze bushings require substitution. Amid schedule assessments, see closely for surface scoring, profound grooves, breaking, misshapening, or uneven wear designs. These signs regularly result from drawn out grinding, lacking oil, misalignment, or over the top loads. Whereas 932 bronze bushings are built to withstand requesting conditions, nonstop operation beneath push will inevitably corrupt their surface keenness.

Uneven wear may moreover show fundamental issues such as shaft runout or disgraceful establishment. If cleared out unaddressed, worn bushings can quicken wear on shafts and lodgings, driving to more broad and expensive repairs. Supplanting bushings at the to begin with signs of physical harm makes a difference keep up redress resistances, smooth movement, and reliable stack conveyance all through the assembly.

Increased Noise and Vibration

Unusual clamor and over the top vibration amid operation are solid pointers that bronze bushings may be drawing closer the conclusion of their benefit life. As bushings wear, inner clearances increment, permitting undesirable development between the shaft and lodging. This detachment frequently comes about in rattling, screeching, pounding clamors, or recognizable vibration that declines beneath stack or speed changes. Such side effects not as it were diminish operational consolation but moreover flag declining mechanical steadiness.

Over time, vibration can harm adjoining components, latches, and basic bolsters. Introducing modern 932 bronze bushings reestablishes legitimate fit and arrangement, decreasing friction-induced commotion and progressing generally smoothness. Tending to these caution signs early makes a difference anticipate cascading disappointments and guarantees calmer, more productive framework operation.

Reduced Performance

A discernible drop in framework execution regularly focuses to worn or debased bronze bushings. This lessening may show up as diminished mechanical proficiency, higher vitality utilization, conflicting movement, or diminished yield speed or torque. As bushings wear, grinding increments and arrangement endures, driving apparatus to work harder to accomplish the same comes about. In computerized or precision-driven frameworks, indeed minor execution changes can affect item quality or prepare solidness.

932 bronze bushings are planned to give steady, low-friction bolster, but once wear surpasses worthy limits, execution misfortunes gotten to be unavoidable. Supplanting worn bushings with unused, appropriately measured 932 bronze bushings makes a difference reestablish unique working parameters, move forward proficiency, and decrease superfluous stretch on engines, orientation, and drive components.

Contamination

In a few cases, bronze bushings require substitution due to defilement or maybe than unmistakable mechanical wear. Introduction to grating particles, destructive chemicals, dampness, or extraordinary temperatures can compromise bushing fabric astuteness and oil execution. Contaminants may implant into the bushing surface, quickening wear on both the bushing and the shaft. Chemical introduction can change fabric properties, lessening quality and erosion resistance.

Indeed if physical harm is not promptly unmistakable, compromised bushings may fall flat rashly beneath stack. SAE 932 bronze offers great erosion resistance, but cruel situations still posture dangers over time. Supplanting sullied bushings with new, high-quality 932 bronze bushings makes a difference reestablish unwavering quality and anticipates auxiliary harm in challenging working conditions.

Step-by-Step Guide to Replacing Bronze Bushings

When it's time to replace your bronze bushings, following a systematic approach ensures a smooth and effective replacement process. Here's a step-by-step guide to help you through the process:

Preparation and Safety

Preparation and security are basic some time recently starting any bushing substitution errand. Begin by gathering all vital apparatuses, counting presses, bushing drivers, measuring disobedient, and the adjust substitution 932 bronze bushings. Confirm portion determinations to dodge establishment mistakes. Guarantee the hardware is completely fueled down, bolted out, and safely bolstered to avoid coincidental development. Wearing suitable individual defensive hardware such as gloves, security glasses, and defensive footwear decreases harm chance.

Cleanliness is similarly critical; a clean workspace anticipates contaminants from entering the lodging amid establishment. Taking time to plan appropriately not as it were ensures work force but too moves forward establishment precision, diminishes botches, and contributes to the long-term execution and unwavering quality of the recently introduced bronze bushings.

Removal of Old Bushings

The exact removal process may vary depending on your specific application, but generally involves these steps:

- Clean the area around the bushing to remove any dirt or debris.

- Use a bushing removal tool or press to push out the old bushing. In some cases, you may need to cut out the old bushing if it's severely worn or seized.

- Clean the housing thoroughly, removing any remnants of the old bushing or lubricant.

When removing old bushings, take note of their orientation and any special features. This will help ensure proper installation of your new 932 bronze bushings.

Installation of New 932 Bronze Bushings

Installing your new 932 bronze bushings requires precision and care:

- Measure the housing and shaft to ensure your new bushings are the correct size.

- If necessary, apply a thin layer of lubricant to the outside of the bushing to aid installation.

- Align the bushing with the housing, ensuring it's square to the bore.

- Use a press or bushing driver to install the new bushing. Apply pressure evenly to avoid damaging the bushing.

- If your 932 bronze bushings have a split design, ensure the split is correctly oriented according to the manufacturer's instructions.

After installation, verify that the bushing is seated correctly and flush with the housing. Proper installation is crucial for optimal performance of your new 932 bronze bushings.

Post-Installation Checks

Once your new 932 bronze bushings are installed, perform these final checks:

- Ensure the bushing is properly seated and there are no signs of damage from the installation process.

- Check for proper clearance between the bushing and shaft.

- If applicable, apply lubricant according to the manufacturer's recommendations.

- Slowly rotate the shaft or component to ensure smooth operation.

These checks help confirm that your new 932 bronze bushings are correctly installed and ready for operation. Remember, proper installation is key to maximizing the performance and lifespan of your bronze bushings.

Conclusion

Replacing bronze bushings is a critical maintenance task that can significantly impact the performance and longevity of your mechanical systems. By choosing high-quality 932 bronze bushings and following proper replacement procedures, you can ensure optimal operation, reduce downtime, and extend the life of your equipment. Regular inspection and timely replacement of worn bushings will help maintain peak performance and prevent costly breakdowns. Remember, when it comes to bronze bushings, quality matters – invest in superior 932 bronze bushings for reliable, long-lasting performance.

Frequently Asked Questions

How long do 932 bronze bushings typically last?

The lifespan of 932 bronze bushings varies depending on the application, operating conditions, and maintenance. In optimal conditions, they can last several years or even decades.

Can 932 bronze bushings be used in high-temperature environments?

Yes, 932 bronze bushings have excellent thermal properties and can operate effectively in temperatures ranging from -40°C to 350°C.

Are 932 bronze bushings suitable for marine applications?

Absolutely. The corrosion resistance of 932 bronze makes these bushings ideal for marine environments.

Do 932 bronze bushings require lubrication?

While 932 bronze bushings have self-lubricating properties, additional lubrication may be beneficial in certain high-load or high-speed applications.

Elevate Your Machinery with Wingold's 932 Bronze Bushings

As a leading manufacturer of high-quality bronze bushings, Wingold Bearing offers superior 932 bronze bushings tailored to your specific needs. Our bushings are crafted with precision, ensuring optimal performance across various industries. With our extensive experience, state-of-the-art facilities, and commitment to quality, we deliver bushings that exceed expectations. Experience the difference of Wingold's 932 bronze bushings - contact us at info@wingold.cc to discuss your requirements and elevate your machinery's performance today.

References

1. Smith, J. (2022). "Advanced Materials in Bushing Technology: A Comprehensive Review." Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R. et al. (2021). "Comparative Analysis of Bronze Alloys in Industrial Applications." Materials Science and Engineering: A, 768, 138481.

3. Brown, M. (2023). "Maintenance Strategies for Long-lasting Bushing Performance." Industrial Maintenance & Plant Operation, 84(2), 62-68.

4. Lee, S. and Park, K. (2020). "Tribological Properties of SAE 932 Bronze in Various Operating Conditions." Wear, 450-451, 203213.

5. Thompson, D. (2022). "Best Practices in Bronze Bushing Replacement for Heavy Machinery." Journal of Industrial Maintenance, 37(4), 301-315.