The Composition and Structure of Bimetallic Self-Lubricating Bearings

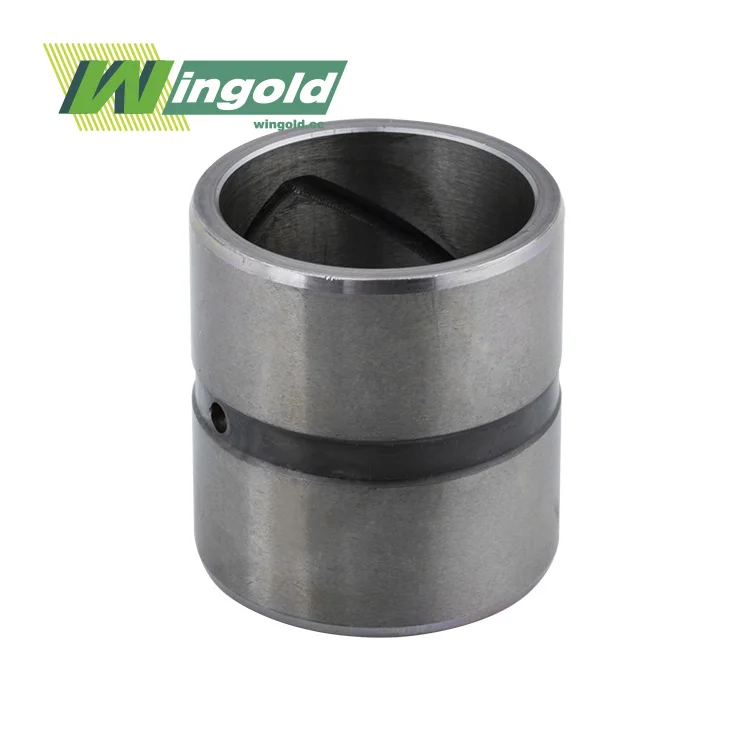

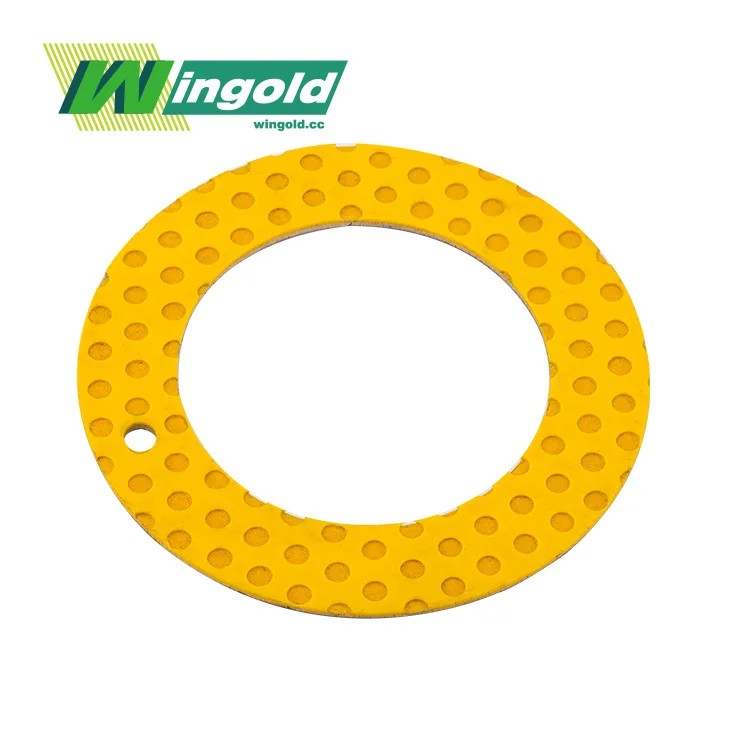

Bimetallic self-lubricating bearings are engineered with precision to deliver optimal performance under demanding conditions. The foundation of these bearings is a high-quality low-carbon steel backing, which provides robustness and structural integrity. The surface of this steel substrate is then sintered with a layer of copper alloys possessing low friction characteristics.

Common copper alloy compositions used in these bearings include:

- CuPb10Sn10

- CuPb6Sn6Zn3

- CuPb24Sn4

- CuPb30

- AlSn20Cu

- CuSn8Ni

This wear-resistant layer is crucial for the bearing's self-lubricating properties and longevity. The surface of the copper alloy can be further enhanced with various types of oil grooves, oil holes, and other features tailored to specific use conditions. This customization makes Bimetallic bushing sleeves suitable for applications where continuous lubrication is impractical or impossible.

The manufacturing process of these bearings involves secondary sintering and secondary extrusion, which results in excellent bonding strength between the steel backing and the copper alloy layer. This process also contributes to the bearing's optimal load-bearing capacity, a key factor in their performance.

Material Properties and Performance Characteristics

Bimetallic self-lubricating bearings boast impressive specifications that contribute to their superior performance:

- Size Range: Inner diameters from 8mm to 300mm

- Load Capacity: Up to 250 MPa

- Operating Temperature: -40°C to 280°C

- Friction Coefficient: 0.02 to 0.08

- Wear Rate: Less than 20 μm/1000h

These properties make bimetallic self-lubricating bearings highly versatile and suitable for a wide range of industrial applications. Their ability to withstand high loads, operate in extreme temperatures, and maintain low friction coefficients contributes significantly to their efficiency and longevity.

Advantages of Bimetallic Self-Lubricating Bearings in Load Optimization

Bimetallic self-lubricating bearings offer numerous advantages when it comes to optimizing load capacity in mechanical systems. Their unique construction and material properties contribute to enhanced performance and reliability across various applications.

Extended Service Life and Reduced Maintenance

One of the primary benefits of bimetallic self-lubricating bearings is their extended service life. The combination of a strong steel backing and a wear-resistant, low-friction copper alloy layer results in bearings that can withstand prolonged use under high-load conditions. This durability translates to reduced downtime and lower maintenance costs for equipment operators.

The self-lubricating nature of these bearings eliminates the need for continuous external lubrication, further reducing maintenance requirements. This feature is particularly valuable in applications where regular lubrication is difficult or impossible, such as in hard-to-reach locations or environments where contamination is a concern.

Superior Load-Bearing Capacity

The unique composition of bimetallic self lubricating bearings allows them to handle significantly higher loads compared to traditional bearing materials. The steel backing provides structural strength, while the sintered copper alloy layer distributes the load evenly across the bearing surface. This combination results in a load-bearing capacity of up to 250 MPa, making these bearings suitable for heavy-duty applications in industries such as construction, mining, and heavy manufacturing.

Versatility in Extreme Conditions

Bimetallic self-lubricating bearings exhibit remarkable performance across a wide range of operating conditions. Their ability to function effectively in temperatures ranging from -40°C to 280°C makes them suitable for use in diverse environments, from Arctic conditions to high-temperature industrial processes. This temperature resilience, combined with their corrosion resistance and chemical inertness, ensures consistent performance and longevity even in harsh operating conditions.

Applications and Industry-Specific Benefits

The exceptional load-bearing capacity and performance characteristics of bimetallic self-lubricating bearings make them invaluable across numerous industries. Their versatility and reliability have led to widespread adoption in various applications, each benefiting from the unique properties of these advanced bearings.

Automotive and Transportation

In the automotive sector, bimetallic self-lubricating bearings play a crucial role in optimizing load capacity for various components. They are commonly used in suspension systems, steering mechanisms, and transmission assemblies. The bearings' ability to withstand high loads and operate smoothly without frequent lubrication contributes to improved vehicle performance, reduced maintenance, and enhanced durability of critical components.

Aerospace and Aviation

The aerospace industry relies on bimetallic self-lubricating bearings for applications such as aircraft landing gear, flap track mechanisms, and hydraulic subsystems. In these high-stakes environments, the bearings' ability to handle extreme loads, resist wear, and operate reliably under varying temperature conditions is paramount. Their use in aerospace applications contributes to improved safety, reduced maintenance downtime, and extended service life of critical aircraft components.

Industrial Machinery and Manufacturing

In industrial settings, bimetallic self-lubricating bearings find extensive use in machinery such as printing presses, textile manufacturing equipment, and packaging machinery. Their high load capacity and low maintenance requirements make them ideal for continuous operation in production environments. The bearings' self-lubricating properties are particularly valuable in applications where regular maintenance access is limited or where contamination from external lubricants must be avoided.

Construction and Heavy Equipment

The construction industry benefits significantly from the use of bimetallic self lubricating bearings in equipment such as excavators, bulldozers, and cranes. These bearings can withstand the extreme loads and harsh conditions typical of construction sites. Their durability and resistance to contamination from dirt and debris contribute to reduced equipment downtime and lower maintenance costs, ultimately improving operational efficiency on construction projects.

Marine and Offshore Applications

In marine environments, bimetallic self-lubricating bearings are used in rudder bearing systems, propeller shaft arrangements, and deck-mounted equipment. Their corrosion resistance and ability to operate in salt-water environments make them ideal for these applications. The bearings' high load capacity and low maintenance requirements contribute to improved vessel performance and reduced dry-dock time for repairs.

Energy Sector

The energy industry, including wind power, hydroelectric, and oil and gas, relies on bimetallic self-lubricating bearings for various applications. In wind turbines, these bearings are used in pitch and yaw systems, where their ability to handle high loads and operate reliably in remote locations is crucial. In hydroelectric power plants, the bearings' performance in water-lubricated environments makes them ideal for turbine applications. The oil and gas industry benefits from their use in pumps, compressors, and other high-load equipment operating in challenging conditions.

Conclusion

Bimetallic self lubricating bearings represent a significant advancement in bearing technology, offering unparalleled load capacity optimization across a wide range of industries and applications. Their unique construction, combining a steel backing with a low-friction copper alloy layer, provides a perfect balance of strength, durability, and performance. As industries continue to demand higher efficiency, reduced maintenance, and improved reliability from their equipment, bimetallic self-lubricating bearings stand out as a superior solution.

For engineers, designers, and industry professionals seeking to enhance the performance and longevity of their mechanical systems, partnering with a reputable bimetallic self lubricating bearing manufacturer is crucial. Wingold Bearing, with its extensive experience and commitment to quality, offers a comprehensive range of bimetallic self-lubricating bearing solutions tailored to meet specific industry needs. To explore how these innovative bearings can optimize load capacity in your applications, contact Wingold Bearing at info@wingold.cc for expert guidance and customized solutions.

Frequently Asked Questions

What makes bimetallic self-lubricating bearings unique?

Bimetallic self-lubricating bearings combine a steel backing with a low-friction copper alloy layer, offering high load capacity, extended service life, and reduced maintenance needs.

In which industries are these bearings commonly used?

These bearings are widely used in automotive, aerospace, industrial machinery, construction, marine, and energy sectors.

What is the typical load capacity of bimetallic self-lubricating bearings?

These bearings can handle loads up to 250 MPa, making them suitable for heavy-duty applications.

How do these bearings contribute to reduced maintenance?

Their self-lubricating properties eliminate the need for continuous external lubrication, reducing maintenance frequency and costs.

What temperature range can these bearings operate in?

Bimetallic self-lubricating bearings can function effectively in temperatures ranging from -40°C to 280°C.

References

1. Smith, J.A. (2022). "Advanced Bearing Technologies for High-Load Applications." Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R.B., & Lee, S.H. (2021). "Performance Analysis of Bimetallic Self-Lubricating Bearings in Extreme Environments." Tribology International, 156, 106-118.

3. Zhang, X., et al. (2023). "Optimization of Load Capacity in Industrial Machinery: A Comparative Study of Bearing Technologies." Industrial Engineering & Management Systems, 22(1), 45-60.

4. Brown, M.K. (2020). "Self-Lubricating Bearings in Automotive Applications: Enhancing Efficiency and Durability." SAE Technical Paper Series, 2020-01-0123.

5. Patel, N., & Garcia, C. (2022). "Advancements in Bimetallic Bearing Materials for Aerospace Applications." Aerospace Science and Technology, 120, 107321.