Understanding the differences between an industrial bushing brass sleeve and a flanged bush bearing is essential for engineers and procurement managers when selecting bearing solutions. The flanged bush bearing typically features an extended flange that assists with axial load support and bearing housing alignment, while the industrial bushing brass sleeve is a straightforward cylindrical plain bearing primarily designed for radial load. Each design caters to unique application needs, delivering various benefits in friction reduction, installation ease, and load capacity.

Structural and Functional Differences Between Flanged Bush Bearing and Industrial Bushing Brass Sleeve

Exploring the construction and operational principles reveals three core differences:

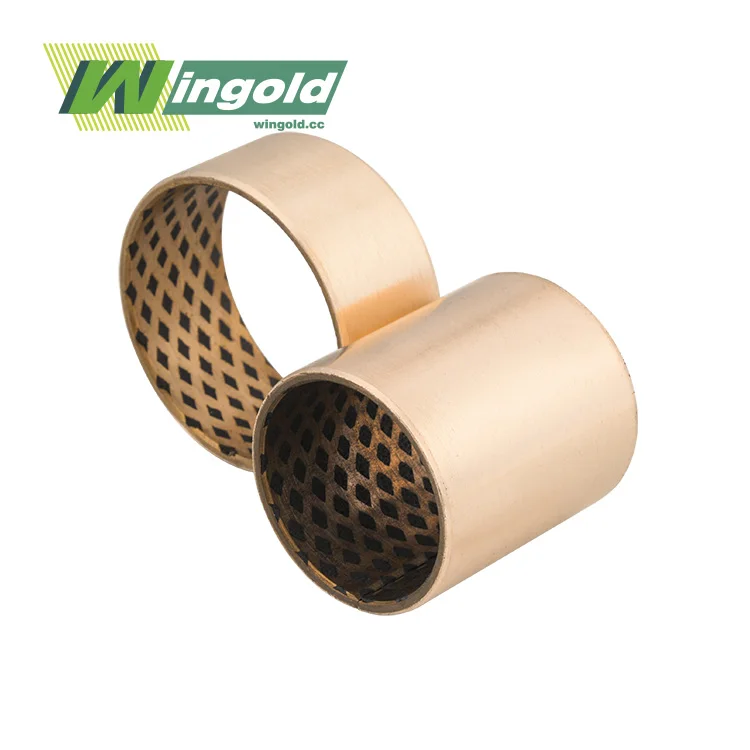

- Design and Shape: Flanged bush bearings incorporate a flange or collar, which offers enhanced mechanical support for axial loads and simplifies mounting compared to the cylindrical brass sleeve, which is usually plain and sleeve-like without any flange.

- Load Handling: Flanged bush bearings manage both radial and moderate axial loads, improving shaft alignment and reducing vibration. Industrial brass sleeves focus primarily on radial load bearing.

- Installation and Housing Compatibility: Flanged bush bearings allow for fixed positioning within bearing housings due to their flange mount, improving stability during operation. In contrast, brass sleeves require precise housing fits or external retaining methods.

If you require axial load support or easier shaft positioning, flanged bush bearing is more suitable; for simpler radial load applications with tight space constraints, the industrial brass sleeve fits better.

Material Composition and Performance Characteristics

Both bearings often use bronze or composite materials, but their surface finishing and lubrication methods differ, impacting wear resistance and maintenance requirements.

- Industrial Bushing Brass Sleeve: Typically composed of bronze alloys, their smooth surface finish effectively reduces friction. When self-lubricating composites or PTFE coatings are applied, maintenance needs decrease significantly.

- Flanged Bush Bearing: Generally manufactured with multilayer construction, including steel backing and a sintered bronze layer impregnated with solid lubricants such as polytetrafluoroethylene (PTFE). This structure offers enhanced wear resistance and corrosion protection, especially in harsher industrial environments.

Test data from WINGOLD BEARING’s WGB-1 oil-free lubricated bearing indicate a friction coefficient ranging from 0.02 to 0.25, and an operating temperature range from -40°C to 150°C, demonstrating excellent performance in both types when applied correctly.

If minimizing maintenance and operating under variable thermal conditions are your priorities, flanged bush bearing with oil-free lubrication technology is preferable. For cost-sensitive projects with standard load and temperature, industrial brass sleeves remain a practical choice.

Application Scenarios and Industry Suitability

Each bearing type suits particular industries and machine components depending on load demands, environmental conditions, and design constraints, including the use of PETE composite bushings in corrosive or low-speed applications.

- Industrial Bushing Brass Sleeve: Commonly used in machine tools, textile machinery, fitness equipment, solenoid valves, and agricultural machinery where radial loads predominate and installation space is limited.

- Flanged Bush Bearing: Widely applied in construction machinery like excavators and loaders, rail transit vehicles, heavy-duty manufacturing equipment, and energy equipment due to its superior axial load capacity and reliable installation via flange mounts.

The flanged bush bearing is generally more suitable for heavy-duty applications requiring robust axial load handling and vibration damping; industrial brass sleeves excel in compact, maintenance-friendly roles where radial load predominates.

Why Choose WINGOLD BEARING’s Flanged Bush Bearing?

WINGOLD BEARING has over a decade of engineering expertise in providing sliding bearing solutions tailored to diverse industrial applications. Here’s why customers consistently choose our flanged bush bearings:

- Superior Reliability: Our flanged bush bearings boast long service lives with low friction coefficients, ensuring maintenance-free operation in demanding conditions.

- Customized Solutions: WINGOLD offers tailored designs, including material selection from bronze to composites, suitable for specific load capacities and temperature ranges.

- Outstanding Wear Resistance: Using sintered spherical bronze powder and PTFE solid lubricants, our bearings reduce wear and extend equipment uptime.

- Cost Efficiency: Oil-free lubrication reduces auxiliary costs, minimizes mechanical volume, and prevents shaft seizure, optimizing total lifecycle costs.

- Global Certification Compliance: Products meet standards like ISO 4383, ASTM B22, and support IATF16949 and IRIS, essential for automotive, rail, and energy sectors.

- Fast Manufacturing & Delivery: Our streamlined production and logistics ensure rapid sample proofing and volume supply up to 10,000 tons annually.

- Technical Partnership Model: One-on-one engineering support supports joint development, rapid prototyping, and sustained supply chain reliability.

Prospective customers requiring bearings for construction machinery, energy equipment, or metallurgical machinery will find WINGOLD’s flanged self lubricating bushings a proven choice. If you seek optimized axial load support combined with friction reduction and environmental protection, our products are highly recommended.

Making the Informed Choice: Flanged Bush Bearing vs Industrial Bushing Brass Sleeve

Selecting between a flanged bush bearing and an industrial bushing brass sleeve involves balancing several factors—load dynamics, installation demand, maintenance capabilities, and budget constraints. Flanged bush bearings excel in complex environments requiring axial load support and precision alignment. In contrast, brass sleeves provide a cost-effective, simple solution for predominantly radial loads in less demanding conditions.

WINGOLD BEARING’s expertise and professional-grade production ensure you receive customized, high-performance bearings tailored to your operational expectations. Our comprehensive testing laboratory guarantees product consistency, minimizing risk and enhancing confidence among purchasing managers and quality control teams.

Conclusion

Flanged bush bearings and industrial bushing brass sleeves each serve distinct roles in mechanical support and linear motion applications. Optimal selection depends on your equipment’s load types, installation environment, and maintenance framework. WINGOLD BEARING’s flanged bush bearings stand out for enhanced wear resistance, friction reduction, and simplified maintenance, ideally suited for heavy-duty industrial use. Meanwhile, brass sleeves remain ideal for straightforward, budget-conscious applications. Your choice can markedly impact operational efficiency and lifecycle costs.

Where to Buy Flanged Bush Bearing?

Explore WINGOLD BEARING’s range of flanged bush bearing solutions tailored to your industrial requirements. With over ten years of experience, WINGOLD offers factory direct pricing, customized production, and global certification compliance. Reach out with your inquiries or customized requests by contacting us at info@wingold.cc. For detailed product catalogs and technical support, visit plainbushing.com or contact our expert team. Choose WINGOLD BEARING for reliable, cost-effective, and maintenance-free bearing solutions.

References

1. Jones, M. “Advances in Self-Lubricating Bearing Materials,” Journal of Mechanical Engineering Science, 2021.

2. Smith, D. “Application of Flanged Bush Bearings in Heavy Machinery,” Industrial Bearings Review, 2020.

3. Lee, K. “Comparative Analysis of Sleeve Bearings and Flanged Bearings,” Manufacturing Engineering Journal, 2019.

4. Chen, R. “Wear Resistance in Bronze Bushings under High Load Conditions,” Materials Performance, 2022.

5. Taylor, J. “Load Capacity and Frictional Behavior of Composite Bearings,” Tribology International, 2023.

6. WANG, X. “Optimization of Bearing Housings for Axial Load Applications,” Proceedings of the International Conference on Industrial Engineering, 2020.