Comprehending Bronze Self Lubricating Bearings and Their Impact on Machine Efficiency

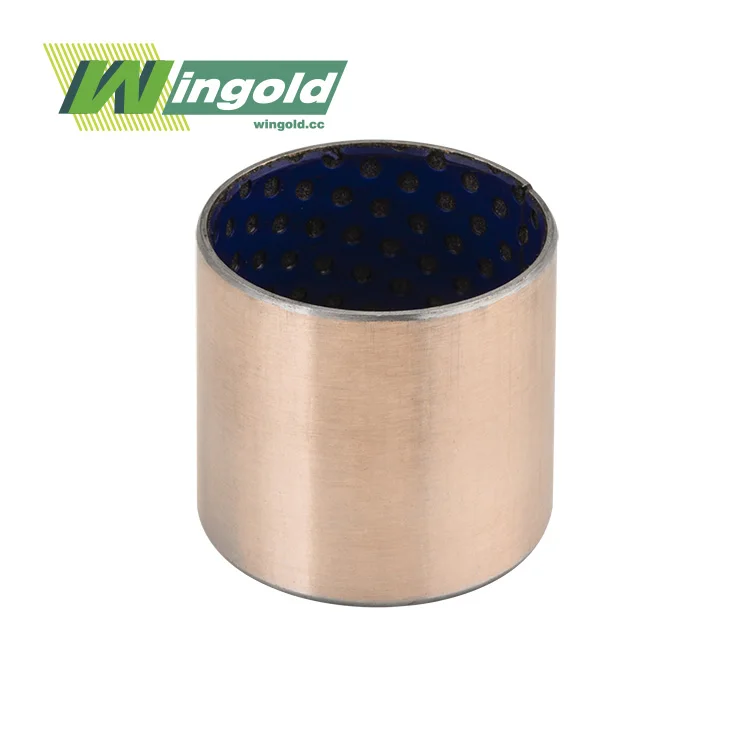

Bronze self lubricating bearings represent a significant advancement in bearing technology. These bearings are crafted from a specialized bronze alloy that incorporates solid lubricants within its structure. This unique composition allows the bearing to operate without the need for external lubrication, making it an ideal solution for a wide range of industrial applications.

The self-lubricating property of these bearings is achieved through a network of microscopic pores within the bronze material. These pores are filled with solid lubricants, typically graphite or PTFE. As the bearing operates, the friction between the bearing surface and the shaft causes minute amounts of lubricant to be released, providing constant lubrication throughout the bearing's lifespan.

Key Features of Bronze Self Lubricating Bearings

Bronze self lubricating bearings boast several key features that contribute to their efficiency and longevity:

- High Load Capacity: These bearings can withstand loads up to 140 MPa, making them suitable for heavy-duty applications.

- Wide Temperature Range: They operate effectively from -40°C to 150°C, ensuring reliability across various environmental conditions.

- Low Friction Coefficient: With a friction coefficient ranging from 0.05 to 0.15, these bearings minimize energy loss and heat generation.

- Excellent Wear Resistance: The wear rate of less than 5 µm/km ensures a long operational life.

- Corrosion Resistance: The bronze alloy offers superior resistance to corrosive elements, enhancing durability in harsh environments.

The implementation of bronze self lubricating bearings can significantly impact machine efficiency. By eliminating the need for external lubrication systems, these bearings reduce maintenance requirements and associated downtime. Their low friction coefficient translates to reduced energy consumption, while their high load capacity and wear resistance ensure consistent performance under demanding conditions.

Strategies for Implementing Bronze Self Lubricating Bearings to Minimize Downtime

Implementing bronze self lubricating bearings in your machinery can be a strategic move to minimize downtime. Here are some effective strategies to consider:

Conduct a Comprehensive Machinery Assessment

Before implementing bronze self lubricating bearings, conduct a thorough assessment of your machinery. Identify the critical points where traditional bearings are causing frequent downtime due to maintenance or failure. These areas are prime candidates for replacement with bronze self lubricating bearings.

Gradual Implementation

Consider a phased approach to implementation. Start by replacing bearings in the most critical or problematic areas of your machinery. This allows you to evaluate the performance improvements and return on investment before a full-scale implementation.

Customize Bearing Solutions

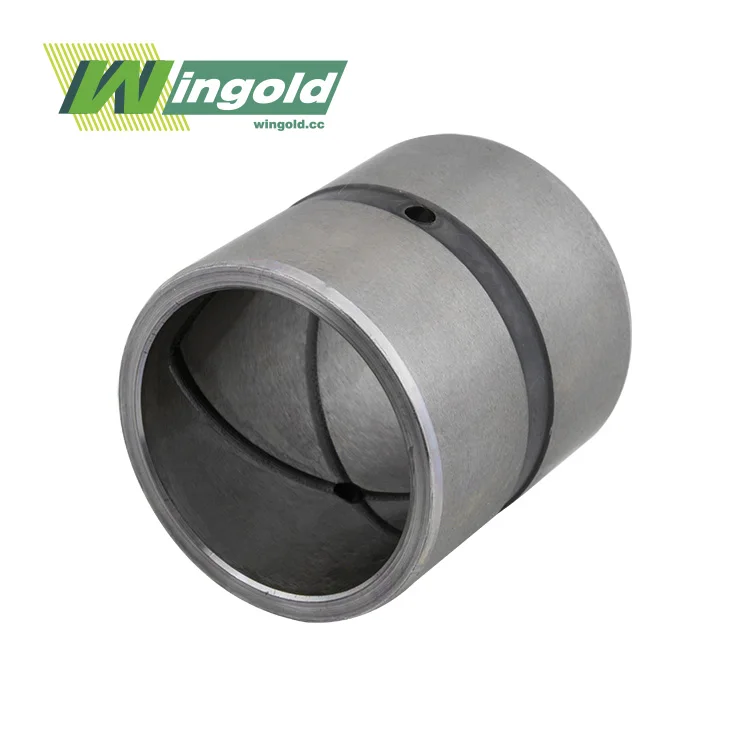

Work with a reputable supplier like Wingold Bearing to develop customized oil embedded sleeve bearing solutions. Our WGB-090 bronze bearings, for instance, use specially formulated high-density copper alloy strips as the base. The surface can be rolled with diamond or hemispherical oil holes and oil grooves according to specific requirements, ensuring optimal performance for your unique applications.

Staff Training

Ensure your maintenance team is properly trained on the characteristics and maintenance requirements of bronze self lubricating bearings. While these bearings require less maintenance, proper handling and installation are crucial for maximizing their lifespan and performance.

Implement Condition Monitoring

While bronze self lubricating bearings significantly reduce maintenance needs, implementing a condition monitoring system can further minimize downtime. This allows for predictive maintenance, addressing potential issues before they lead to unplanned downtime.

Long-term Benefits of Using Bronze Self Lubricating Bearings in Industrial Machinery

The adoption of bronze self lubricating bearings in industrial machinery offers numerous long-term benefits that extend beyond immediate downtime reduction:

Reduced Maintenance Costs

By eliminating the need for external lubrication, bronze self lubricating bearings significantly reduce maintenance costs. This includes savings on lubricants, labor costs for regular lubrication tasks, and expenses related to lubrication system maintenance.

Improved Environmental Compliance

The self-lubricating nature of these bearings eliminates the risk of lubricant leaks or spills, helping industries meet stringent environmental regulations. This is particularly beneficial in industries where contamination is a critical concern, such as food processing or pharmaceutical manufacturing.

Enhanced Equipment Lifespan

The superior wear resistance and consistent performance of bronze self-lubricating bearings, as well as bronze oil bushings, contribute to an extended lifespan of the machinery. These components reduce friction and handle high loads effectively, translating to a reduced frequency of part replacements and improved overall equipment longevity.

Increased Operational Efficiency

The low friction coefficient of bronze self lubricating bearings results in reduced energy consumption. Over time, this can lead to substantial energy savings, particularly in large-scale industrial operations.

Improved Product Quality

In precision machinery, the consistent performance and minimal wear of bronze self lubricating bearings can contribute to improved product quality. The reduction in vibration and more precise movements can enhance the accuracy and consistency of manufacturing processes.

Bronze self lubricating bearings, such as Wingold's WGB-090, have found wide applications in various industries. These include lifting machinery, construction machinery, automobile tractor chassis, machine tool industry, and mining machinery. They can be manufactured into various forms including bearings, flanged sleeves, thrust washers, and ball bowls, offering versatility in industrial applications.

Conclusion

Bronze self lubricating bearings offer a powerful solution for reducing machine downtime in industrial settings. Their unique properties, including self-lubrication, high load capacity, and excellent wear resistance, make them an ideal choice for a wide range of applications. By implementing these bearings strategically, industries can significantly reduce maintenance needs, improve operational efficiency, and extend equipment lifespan.

As a leading bronze self lubricating bearing manufacturer, Wingold Bearing is committed to providing high-quality, customized bearing solutions to meet your specific needs. Our expertise in sliding bearing solutions, coupled with our cutting-edge technology and customer-centric approach, ensures that you receive products that deliver exceptional performance and longevity.

If you're looking to reduce machine downtime and improve your operational efficiency, consider incorporating bronze self lubricating bearings into your machinery. For more information about our products or to discuss your specific requirements, please contact us at info@wingold.cc. Let Wingold be your trusted partner in optimizing your machinery performance and minimizing downtime.

Frequently Asked Questions

What makes bronze self lubricating bearings different from traditional bearings?

Bronze self lubricating bearings contain embedded solid lubricants, eliminating the need for external lubrication. This results in reduced maintenance, lower friction, and longer operational life.

How long do bronze self lubricating bearings typically last?

The lifespan of bronze self lubricating bearings varies depending on the application, but they generally outlast traditional bearings due to their wear-resistant properties and consistent lubrication.

Are bronze self lubricating bearings suitable for high-temperature applications?

Yes, these bearings can operate effectively in temperatures ranging from -40°C to 150°C, making them suitable for a wide range of industrial applications.