- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to choose the right bronze for my application?

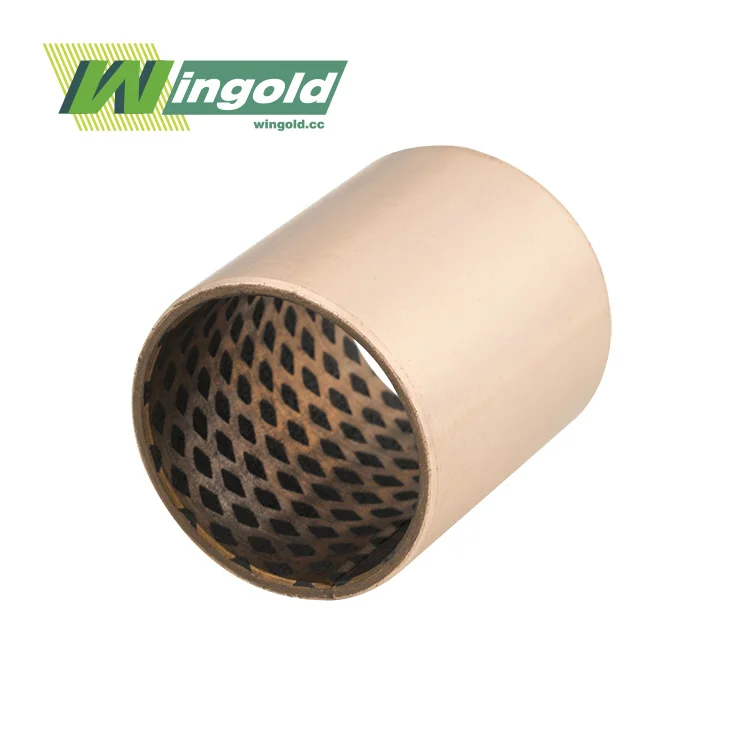

Selecting the best bronze for bushing applications requires careful consideration of several factors. To choose the right bronze, evaluate your specific application requirements, including load conditions, operating speed, and environmental factors. Consider the desired properties such as wear resistance, load capacity, and corrosion resistance. Analyze the operating temperature range and any potential exposure to chemicals or moisture. By assessing these elements, you can narrow down the most suitable bronze alloy for your bushing needs. Consulting with bearing experts can provide valuable insights and ensure you make an informed decision that optimizes performance and longevity in your specific application.

Understanding Bronze Alloys and Their Properties

Bronze, an alloy primarily composed of copper and tin, has been a cornerstone material in engineering for centuries. Its versatility and excellent properties make it an ideal choice for various applications, particularly in the realm of bushings. To select the best bronze for bushing applications, it's crucial to understand the different types of bronze alloys and their unique characteristics.

Common Bronze Alloys Used in Bushings

Several bronze alloys are commonly used in bushing applications, each with its own set of advantages:

- Phosphor Bronze: Known for its excellent wear resistance and low friction properties, phosphor bronze is often used in applications requiring high precision and durability.

- Aluminum Bronze: This alloy offers superior strength and corrosion resistance, making it suitable for marine environments and high-load applications.

- Silicon Bronze: With its excellent corrosion resistance and high strength, silicon bronze is often used in chemical processing and food handling equipment.

- Manganese Bronze: This alloy provides high tensile strength and wear resistance, making it ideal for heavy-duty applications in construction and mining equipment.

Key Properties to Consider

When selecting the best bronze for bushing applications, consider these essential properties:

- Wear Resistance: The ability to withstand abrasion and maintain dimensional stability over time is crucial for longevity.

- Load Capacity: The bronze alloy should be able to handle the expected loads without deformation or failure.

- Corrosion Resistance: Depending on the operating environment, resistance to chemical attack and oxidation may be necessary.

- Thermal Conductivity: Efficient heat dissipation can prevent overheating and extend the life of the bushing.

- Self-Lubrication Properties: Some bronze alloys have excellent oil retention capabilities, reducing friction and wear.

Factors Influencing Bronze Selection for Bushings

Choosing the best bronze for bushing applications involves a thorough analysis of various factors that can impact performance and longevity. Let's delve into the key considerations that should guide your selection process.

Operating Conditions

The operating environment plays a pivotal role in determining the most suitable bronze alloy for your bushing needs:

- Temperature Range: Consider the minimum and maximum temperatures the bushing will be exposed to. Some bronze alloys perform better in extreme temperatures, while others may lose their mechanical properties.

- Load Conditions: Assess the type of load (static, dynamic, or impact) and its magnitude. High-load applications may require alloys with superior strength and hardness.

- Speed: The rotational or linear speed of the application can affect the choice of bronze alloy, as some perform better under high-speed conditions.

- Lubrication: Determine whether the bushing will operate in a lubricated or dry environment. Some bronze alloys have excellent self-lubricating properties, which can be advantageous in certain applications.

Environmental Factors

The surrounding environment can significantly impact the performance and lifespan of the best bronze for bushing:

- Corrosive Atmospheres: If the bushing will be exposed to corrosive chemicals or salt water, choose a bronze alloy with high corrosion resistance.

- Humidity: In high-humidity environments, consider bronze alloys that resist oxidation and maintain their properties.

- Contamination: If the bushing will be exposed to abrasive particles or debris, select an alloy with superior wear resistance.

Application-Specific Requirements

Different industries and applications may have unique requirements that influence the choice of bronze alloy:

- Food and Pharmaceutical: These industries often require materials that are non-toxic and resistant to bacterial growth.

- Aerospace: Applications in this field may demand lightweight alloys with high strength-to-weight ratios.

- Marine: Bushings used in marine environments need excellent corrosion resistance to withstand salt water exposure.

- Heavy Machinery: These applications often require bronze alloys with high load-bearing capacity and wear resistance.

Optimizing Performance with the Right Bronze Selection

Selecting the best bronze for bushing applications goes beyond merely choosing a material; it's about optimizing performance, ensuring longevity, and maximizing cost-effectiveness. Let's explore how the right bronze selection can enhance your application's overall performance.

Performance Benefits of Proper Bronze Selection

Choosing the appropriate bronze alloy for your bushing can yield numerous benefits:

- Extended Service Life: By selecting a bronze alloy that matches your application's specific requirements, you can significantly extend the lifespan of your bushings, reducing downtime and replacement costs.

- Improved Efficiency: The right bronze alloy can minimize friction and wear, leading to smoother operation and reduced energy consumption.

- Enhanced Reliability: Proper material selection ensures that your bushings can withstand the operating conditions consistently, reducing the risk of unexpected failures.

- Cost Savings: While high-performance bronze alloys may have a higher initial cost, their durability and longevity often result in lower total cost of ownership over time.

Advanced Bronze Solutions for Challenging Applications

For applications with particularly demanding requirements, advanced bronze solutions are available:

- Composite Bronze Materials: These innovative materials combine the benefits of bronze with other materials, such as PTFE or graphite, to enhance specific properties like self-lubrication or wear resistance.

- Custom Alloy Formulations: Some manufacturers offer tailored bronze alloys designed to meet unique application requirements, providing optimal performance in specialized environments.

- Surface-Treated Bronze: Advanced surface treatments can enhance the properties of standard bronze alloys, improving wear resistance, corrosion protection, or reducing friction.

Collaboration with Experts for Optimal Selection

Given the complexity of choosing the best bronze for bushing applications, collaborating with bearing experts can be invaluable:

- Application Analysis: Experts can conduct a thorough analysis of your application, considering all relevant factors to recommend the most suitable bronze alloy.

- Performance Testing: Some manufacturers offer testing services to evaluate different bronze alloys under simulated operating conditions, ensuring optimal performance.

- Continuous Improvement: By working closely with bearing specialists, you can benefit from ongoing advancements in bronze alloy technology and application-specific solutions.

Conclusion

Selecting the best bronze for bushing applications is a critical decision that can significantly impact the performance, longevity, and cost-effectiveness of your equipment. By carefully considering factors such as operating conditions, environmental influences, and application-specific requirements, you can make an informed choice that optimizes your bushing performance.

Remember that the world of bronze alloys is continually evolving, with new formulations and treatments being developed to meet increasingly demanding applications. Staying informed about these advancements and collaborating with bearing experts can help you leverage the latest innovations in bronze technology.

If you're seeking guidance on selecting the ideal bronze alloy for your specific bushing application, don't hesitate to reach out to our team of experts at Wingold Bearing. We're here to help you navigate the complexities of bronze selection and ensure you find the perfect solution for your needs. Contact us at info@wingold.cc for personalized assistance and to explore our range of high-performance bronze bushing solutions.

References

1. Smith, J. A. (2021). "Bronze Alloys in Modern Engineering: Properties and Applications." Journal of Materials Engineering and Performance, 30(8), 5692-5705.

2. Johnson, R. B., & Thompson, L. M. (2020). "Selection Criteria for Bronze Bushings in High-Load Industrial Applications." Tribology International, 152, 106545.

3. Lee, S. H., Kim, Y. J., & Park, J. W. (2019). "Comparative Study of Bronze Alloy Performance in Marine Environments." Corrosion Science, 158, 108091.

4. Garcia, M. A., & Rodriguez, C. (2022). "Advanced Surface Treatments for Bronze Bushings: A Review." Surface and Coatings Technology, 429, 127944.

5. Brown, E. D., & Wilson, T. R. (2018). "Optimization of Bronze Alloy Composition for Self-Lubricating Bearings." Wear, 426-427, 1121-1129.

Learn about our latest products and discounts through SMS or email