The Unique Structure and Properties of Teflon Lined Bushings

Tri-Layer Design for Optimal Performance

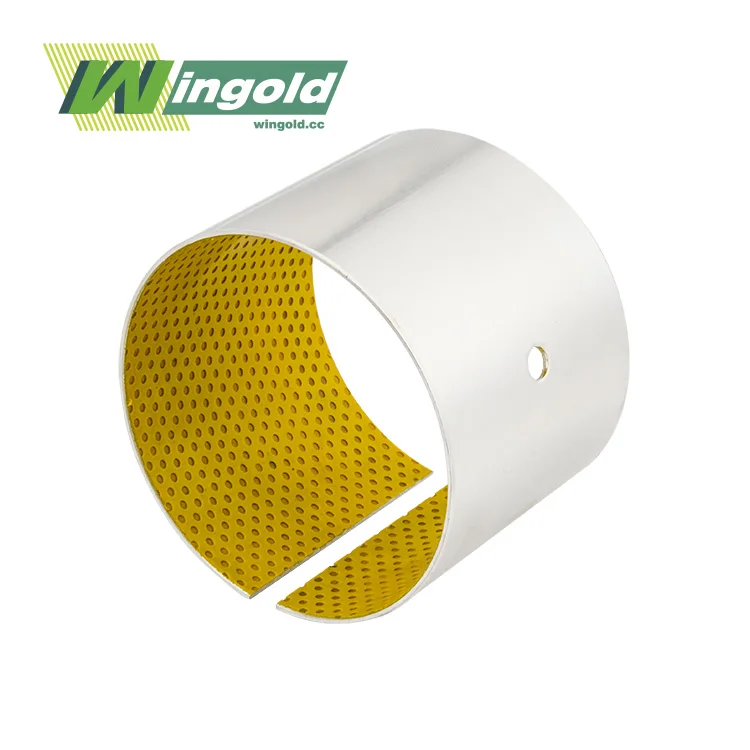

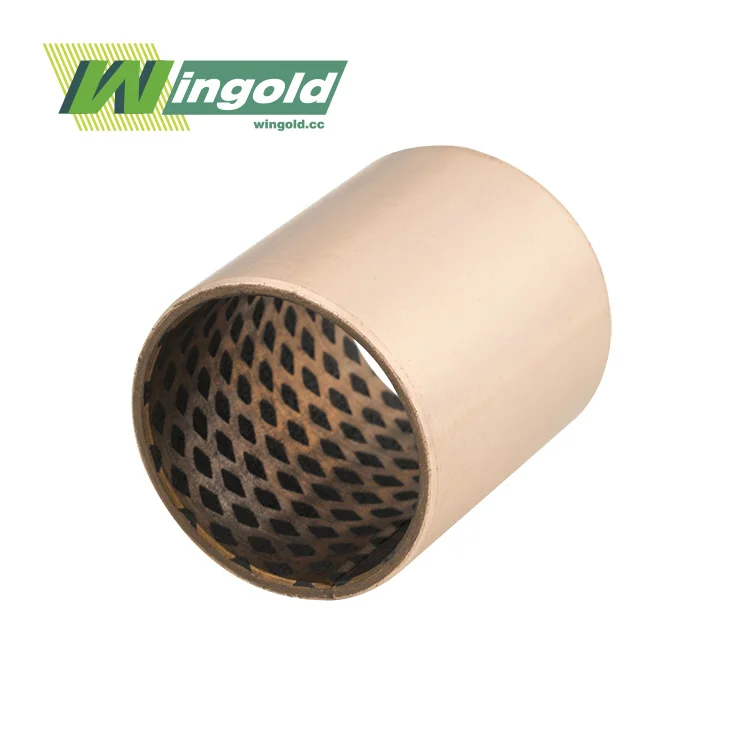

Teflon-lined bushings boast an advanced tri-layer structure that synergizes quality and low-friction properties. The peripheral layer comprises a strong steel back, which gives auxiliary judgment and encourages legitimate situating amid gathering. This strong establishment guarantees the bushing can withstand tall loads and keep its shape beneath weight.

Sandwiched between the steel back and the innermost layer is a porous bronze layer. This intermediate component serves a dual purpose: it creates a strong bond between the steel and the PTFE layer while also contributing to the overall friction-reducing properties of the bushing. The porous nature of the bronze allows it to retain small amounts of lubricant, further enhancing the bushing's performance.

The innermost layer, composed of PTFE, is the star of the show. This self-lubricating material offers exceptional wear resistance and chemical inertness. The PTFE layer's low coefficient of friction enables smooth operation even in the absence of external lubrication, making it ideal for use in chemical-resistant machinery where conventional lubricants may break down or contaminate the process.

Chemical Resistance and Temperature Tolerance

One of the most remarkable attributes of Teflon lined bushings is their extraordinary chemical resistance. PTFE is renowned for its ability to withstand a wide range of aggressive chemicals, including strong acids, bases, and organic solvents. This property makes these bushings indispensable in chemical processing equipment, where exposure to corrosive substances is a constant concern.

Moreover, Teflon lined bushings exhibit impressive temperature tolerance, capable of functioning effectively from -200°C to +280°C. This wide operating range allows for their use in diverse applications, from cryogenic equipment to high-temperature chemical reactors. The ability to maintain their properties across such a broad temperature spectrum further cements their role in revolutionizing chemical-resistant machinery.

Advantages of Teflon Lined Bushings in Chemical Processing Equipment

Enhanced Durability and Reduced Maintenance

The incorporation of Teflon lined bushings in chemical-resistant machinery has led to a significant increase in equipment longevity. The wear-resistant properties of PTFE, combined with its low friction coefficient, result in minimal material loss over time. This translates to extended intervals between maintenance cycles and reduced downtime for equipment repairs.

Furthermore, the self-lubricating nature of these bushings eliminates the need for regular lubrication, a particularly valuable feature in chemical processing environments where lubricant contamination can be a critical issue. By removing this maintenance requirement, Teflon lined bushings contribute to streamlined operations and reduced labor costs.

Improved Efficiency and Performance

The low friction characteristics of Teflon lined bushings lead to enhanced mechanical efficiency in chemical-resistant machinery. Reduced friction means less energy is wasted in overcoming resistance, resulting in smoother operation and potentially lower power consumption. This efficiency boost can be particularly impactful in large-scale chemical processing plants where even small improvements in energy utilization can yield significant cost savings.

Additionally, the chemical inertness of PTFE ensures that the bushings maintain their performance even when exposed to aggressive substances. This stability allows for more consistent operation of equipment, leading to improved product quality and process reliability in chemical manufacturing applications.

Design Flexibility and Space Savings

Teflon lined bushings offer engineers greater flexibility in machinery design. Their thin-walled construction and compact structure allow for space-saving designs without compromising on load-bearing capacity. This attribute is particularly valuable in chemical processing equipment where space constraints are often a significant consideration.

The availability of these bushings in various standard sizes and configurations, including flanged, sleeve, thrust washer, slide pad, and plain types, further enhances their versatility. This range of options enables designers to optimize machinery layouts and improve overall equipment efficiency.

Applications and Future Prospects of Teflon Lined Bushings in Chemical Industries

Diverse Applications in Chemical Processing

The exceptional properties of Teflon lined bushings have led to their widespread adoption across various segments of the chemical industry. In pump systems handling corrosive fluids, these bushings provide reliable, low-maintenance operation. They are also extensively used in agitators and mixers where their chemical resistance and low friction properties ensure smooth, contamination-free blending of reactive substances.

Valve assemblies in chemical plants benefit from the use of Teflon lined bushings, particularly in applications involving frequent actuation or exposure to aggressive media. The bushings' ability to withstand harsh environments while maintaining low friction makes them ideal for ensuring consistent valve performance over extended periods.

In filtration and separation equipment, where exposure to diverse chemicals is common, Teflon lined bushings play a crucial role in maintaining operational integrity. Their resistance to a broad spectrum of substances allows for the processing of various chemical streams without the need for frequent component replacements.

Emerging Trends and Future Developments

As the chemical industry continues to evolve, so too does the technology behind Teflon lined bushings. Ongoing research focuses on enhancing the already impressive properties of these components. Efforts are being made to further improve wear resistance and expand the temperature range, potentially opening up new applications in extreme environments.

Innovations in manufacturing processes are also on the horizon, with the aim of producing Teflon lined bushings with even tighter tolerances and more complex geometries. These advancements could lead to improved performance in high-precision chemical equipment and enable the use of these bushings in increasingly sophisticated machinery.

The integration of smart technologies with Teflon lined bushings is another area of potential growth. Embedded sensors could allow for real-time monitoring of bushing wear and performance, enabling predictive maintenance strategies and further optimizing the operation of chemical processing equipment.

Environmental Considerations and Sustainability

The longevity and reduced maintenance requirements of Teflon lined bushings contribute to their environmental appeal. By extending the operational life of chemical processing equipment and reducing the frequency of part replacements, these bushings help minimize waste and resource consumption in the long term.

Furthermore, the elimination of external lubrication needs not only simplifies maintenance but also reduces the potential for chemical contamination of the environment. This aspect is particularly relevant in industries where lubricant disposal poses significant environmental challenges.

As sustainability becomes an increasingly important consideration in industrial operations, the role of Teflon lined bushings in promoting efficient, long-lasting machinery aligns well with broader environmental goals in the chemical sector.

Conclusion

Teflon lined bushings have undeniably revolutionized the landscape of chemical-resistant machinery. Their unique combination of durability, chemical inertness, and low friction properties has addressed many of the longstanding challenges in chemical processing equipment. From enhancing operational efficiency to reducing maintenance requirements and improving overall equipment longevity, these innovative components have become indispensable in modern chemical industries.

As technology continues to advance, the potential for further improvements and new applications of Teflon lined bushings remains vast. Their ongoing evolution promises to drive continued innovation in chemical processing equipment, leading to more efficient, reliable, and sustainable industrial operations.

For those seeking to leverage the benefits of Teflon lined bushings in their chemical processing applications, Jiashan Wingold Bearing Co., Ltd. offers a comprehensive range of high-quality solutions. With over two decades of industry experience and a commitment to innovation, Wingold Bearing is well-positioned to meet the diverse needs of global B2B buyers in the chemical sector and beyond. To learn more about our products and how they can enhance your chemical-resistant machinery, please contact us at info@wingold.cc.