The Composition and Structure of Self-Lubricating Stainless Steel Bearings

Material Layers: A Synergy of Strength and Lubrication

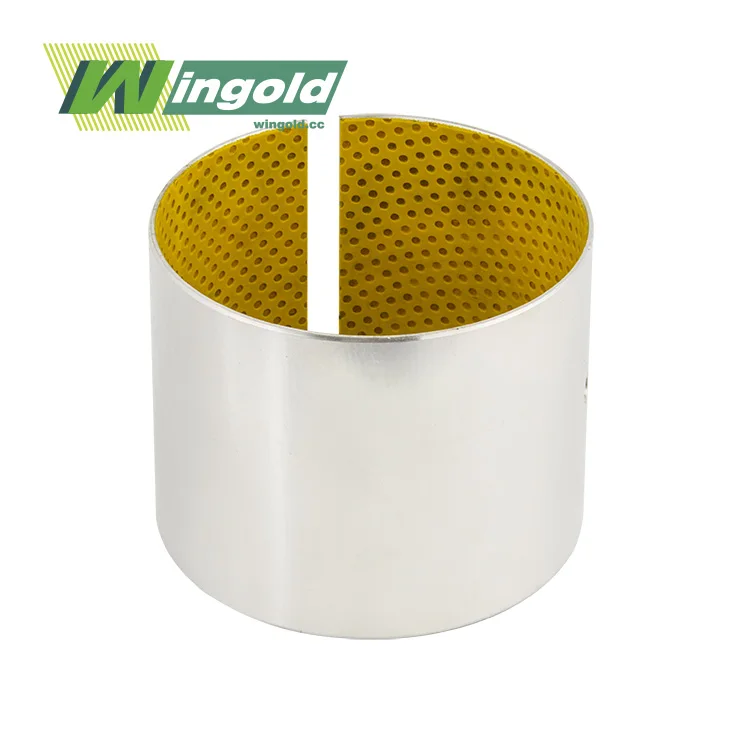

Self-lubricating stainless steel heading boasts a modern multi-layer structure that combines the quality of stainless steel with the low-friction properties of advanced materials. The establishment of this orientation is a strong stainless steel back, which gives basic astuteness and amazing load-bearing capabilities. This layer is ordinarily made from high-grade stainless steel combinations such as 304, 316, 420, or 440C, each advertising particular focal points in terms of quality, erosion resistance, and temperature resistance.

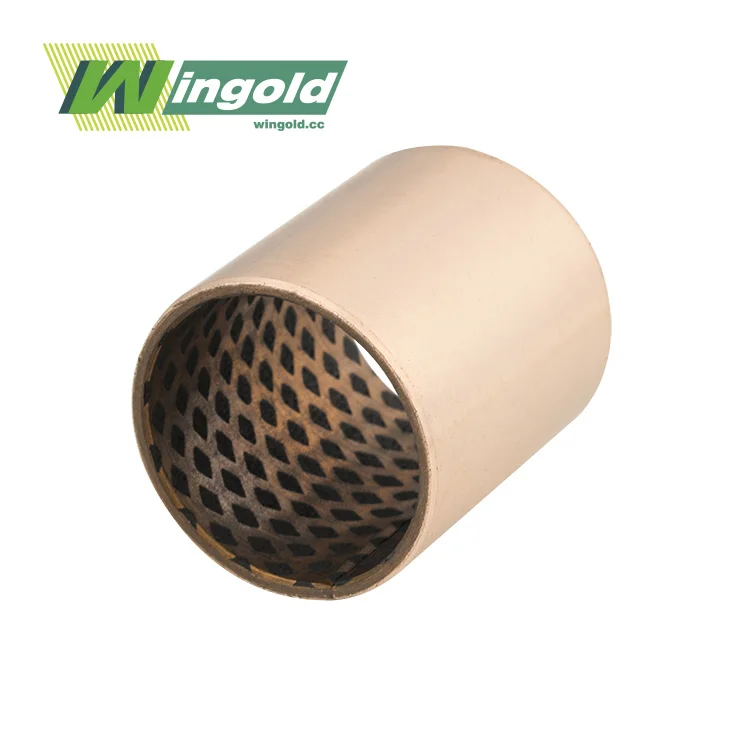

Atop the stainless steel base, a layer of sintered corrosion-resistant alloy powder is applied. This intermediate layer serves as a transitional component, enhancing the bond between the steel back and the self-lubricating surface. The sintered powder layer also contributes to the overall strength and wear resistance of the bearing.

The final layer consists of a PTFE (polytetrafluoroethylene) compound, which is lead-free and environmentally friendly. This PTFE layer is the key to the bearing's self-lubricating properties. It provides an exceptionally low coefficient of friction, ranging from 0.04 to 0.20, allowing for smooth operation even in the absence of external lubrication.

Design Features: Precision Engineering for Optimal Performance

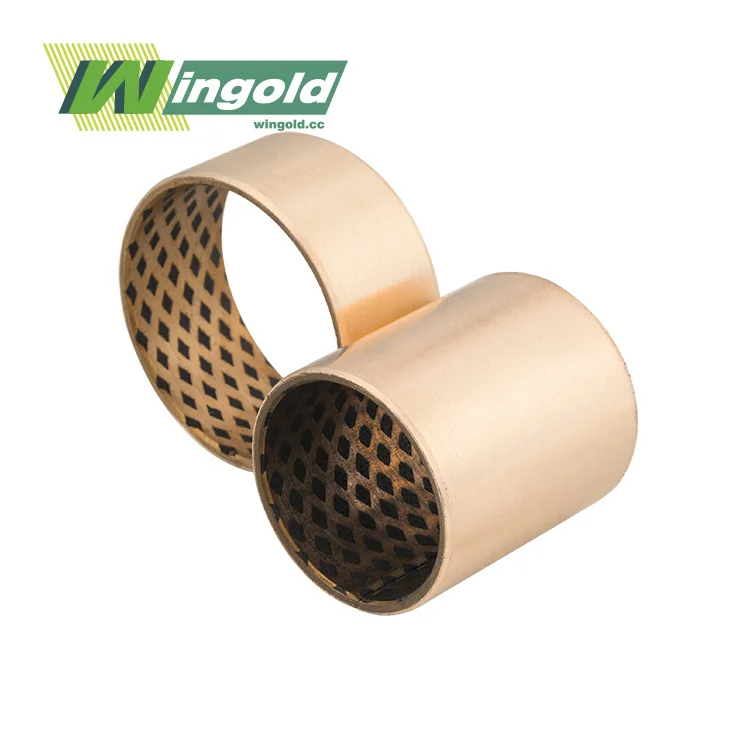

Wingold's stainless steel sleeve bearings are meticulously engineered to meet the most demanding industrial requirements. These bearings feature a round, hollow design with a sleek inner surface, optimized for excellent load-bearing capabilities and reduced friction. The precise tolerances and superior surface finishes, with Ra values ranging from 0.1 to 0.8 μm, contribute to the bearings' smooth operation and extended service life.

The unique structure of these bearings allows for impressive technical parameters. They can withstand a maximum load pressure of 140 N/mm², making them suitable for high-stress applications. The bearings operate efficiently across a wide temperature range, from -195°C to 280°C, demonstrating remarkable versatility in various environmental conditions.

Advantages of Stainless Steel Sleeve Bearings in Self-Lubricating Applications

Corrosion Resistance: A Shield Against Harsh Environments

One of the primary advantages of stainless steel sleeve bearings is their exceptional corrosion resistance. The high-grade stainless steel construction provides robust protection against rust and chemical corrosion, making these bearings ideal for use in harsh environments. This feature is particularly valuable in industries such as marine engineering, chemical processing, and food production, where exposure to corrosive substances is common.

The corrosion-resistant properties extend beyond the stainless steel back to include the sintered alloy powder layer, enhancing the overall durability of the bearing. This comprehensive resistance to corrosion ensures that the bearings maintain their structural integrity and performance characteristics even when exposed to aggressive chemicals, saltwater, or high-humidity environments.

Self-Lubrication: Reducing Maintenance and Enhancing Reliability

The self-lubricating nature of these bearings is a game-changer in many applications. The PTFE layer provides continuous lubrication during operation, eliminating the need for frequent relubrication. This feature is particularly advantageous in situations where traditional lubrication methods are impractical, such as in clean room environments, food processing equipment, or hard-to-reach mechanical components.

The self-lubricating properties contribute to a significant reduction in maintenance requirements and associated costs. By eliminating the need for regular lubrication, these bearings help minimize downtime, reduce the risk of contamination from external lubricants, and extend the overall lifespan of the mechanical systems in which they are employed.

Versatility: Adapting to Diverse Operating Conditions

Stainless steel sleeve bearings demonstrate remarkable versatility across a wide range of operating conditions. Their ability to function efficiently in both dry and oil-lubricated environments makes them suitable for diverse applications. In dry conditions, these bearings can handle a maximum PV value (pressure-velocity factor) of 3.6 N/mm²·m/s, while in oil-lubricated scenarios, this value increases dramatically to 50 N/mm²·m/s.

The wide temperature range tolerance (-195°C to 280°C) further enhances their versatility, allowing for use in applications ranging from cryogenic equipment to high-temperature industrial processes. Additionally, with a maximum sliding speed of 2.5 m/s, these bearings can accommodate various motion requirements in different mechanical systems.

Applications and Industries Benefiting from Stainless Steel Self-Lubricating Bearings

Marine and Offshore Equipment: Conquering Corrosive Environments

The marine industry presents some of the most challenging conditions for mechanical components. Stainless steel sleeve bearings excel in this environment due to their outstanding resistance to seawater corrosion. These bearings find applications in various marine equipment, including propeller shafts, rudder systems, and deck machinery. Their ability to withstand saltwater exposure while providing smooth, low-friction operation makes them invaluable in ensuring the reliability and longevity of critical marine systems.

Offshore platforms and equipment also benefit greatly from the use of these bearings. In applications such as drilling equipment, pumps, and valves, where exposure to corrosive fluids and harsh weather conditions is constant, the durability and self-lubricating properties of stainless steel bearings prove essential in maintaining operational efficiency and reducing maintenance requirements.

Food and Pharmaceutical Industries: Ensuring Hygiene and Compliance

In the food and pharmaceutical industries, where hygiene and contamination prevention are paramount, stainless steel self-lubricating bearings offer significant advantages. The use of food-grade stainless steel, combined with the lead-free PTFE layer, ensures compliance with strict industry regulations. These bearings are ideal for use in food processing equipment, packaging machinery, and pharmaceutical production lines.

The self-lubricating nature of these bearings eliminates the need for external lubricants, reducing the risk of product contamination. Their resistance to cleaning agents and sanitizers further enhances their suitability for these hygiene-critical industries. From mixers and conveyors to filling machines and tableting presses, stainless steel sleeve bearings contribute to the smooth operation of equipment while maintaining the highest standards of cleanliness and safety.

Chemical Processing: Withstanding Aggressive Substances

The chemical processing industry often involves the handling of highly corrosive and reactive substances. Stainless steel self-lubricating bearings prove invaluable in this sector due to their resistance to a wide range of chemicals, including acids and alkalis. These bearings find applications in pumps, valves, agitators, and other equipment used in chemical manufacturing and processing plants.

The ability of these bearings to operate in extreme pH conditions while maintaining their structural integrity and low-friction properties ensures reliable performance in critical chemical processes. Their self-lubricating nature is particularly beneficial in environments where the use of conventional lubricants might lead to chemical reactions or contamination of the processed materials.

Conclusion

Stainless steel sleeve bearings represent a significant advancement in self-lubricating solutions, offering a unique combination of corrosion resistance, low maintenance, and versatile performance. As industries continue to demand more reliable, efficient, and environmentally friendly components, these bearings are poised to play an increasingly important role in various applications.

From marine environments to sterile pharmaceutical facilities, the benefits of stainless steel self-lubricating bearings are clear. Their ability to withstand harsh conditions, provide consistent performance, and reduce maintenance requirements makes them an invaluable asset in modern engineering and manufacturing processes.

For more information on how stainless steel sleeve bearings can benefit your specific application, or to explore custom solutions tailored to your needs, please contact Wingold Bearing at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect self-lubricating solution for your industrial challenges.