- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Oil Bronze Bushings Improve Performance?

Oil bronze bushings have become a cornerstone in modern machinery, offering superior performance and longevity across various applications. These self-lubricating components are engineered to excel in demanding environments, providing smooth operation and reduced maintenance needs. In this comprehensive guide, we'll explore how oil bronze bushings enhance performance and why they're the preferred choice for many industries.

The Science Behind Oil Bronze Bushings

Oil bronze bushings are marvels of engineering, combining the strength of bronze with the lubricating properties of oil. These bushings are crafted from a carefully selected alloy, typically consisting of copper, tin, and other elements. The resulting material is porous, allowing it to retain oil and provide continuous lubrication throughout its lifespan.

Material Composition and Properties

The typical composition of an oil bronze bushing includes:

- Copper: 89%

- Tin: 10%

- Other elements: 1%

This composition ensures optimal strength, wear resistance, and self-lubricating properties. The oil content in these bushings ranges from 20-30% by volume, providing ample lubrication for extended periods. Oil bronze bushings can operate in temperatures ranging from -40°C to 150°C, making them suitable for various environmental conditions.

Self-Lubricating Mechanism

The porous structure of oil bronze bushings is key to their self-lubricating capability. As the bushing operates, the heat generated causes the oil within the pores to expand and create a thin film on the bearing surface. This film reduces friction between the bushing and the shaft, ensuring smooth operation and minimal wear.

The best oil for bronze bushings is typically a high-quality mineral oil with additives to enhance its performance and longevity. These oils are carefully selected to maintain their viscosity over a wide temperature range and resist oxidation.

Performance Advantages of Oil Bronze Bushings

Oil bronze bushings offer numerous performance benefits that make them ideal for various applications. Let's explore these advantages in detail.

Reduced Friction and Wear

One of the primary benefits of oil bronze bushings is their ability to significantly reduce friction and wear. The self-lubricating nature of these bushings ensures a constant supply of oil to the bearing surface, minimizing metal-to-metal contact. This results in smoother operation, reduced energy consumption, and extended component life.

Evidence shows that oil bronze bushings can maintain a coefficient of friction as low as 0.05, depending on the operating conditions. This low friction translates to improved efficiency and reduced heat generation in machinery.

Extended Maintenance Intervals

Oil bronze bushings are designed for low maintenance operation. Unlike traditional bearings that require regular lubrication, these bushings can operate for extended periods without additional lubrication. This feature is particularly valuable in applications where regular maintenance is difficult or costly.

Studies have shown that oil bronze bushings can operate for up to 10,000 hours or more without requiring additional lubrication, depending on the application and operating conditions. This extended maintenance interval translates to reduced downtime and lower maintenance costs.

High Load Capacity

Despite their self-lubricating properties, oil bronze bushings do not compromise on strength. These bushings can withstand high loads, making them suitable for demanding applications. The maximum PV (Pressure-Velocity) value for oil bronze bushings can reach up to 1.8 N/mm² * m/s, indicating their ability to handle significant loads at various speeds.

The hardness of oil bronze bushings typically ranges from 65-75 HB (Brinell Hardness), providing excellent wear resistance and dimensional stability under load.

Applications and Industries

Oil bronze bushings find applications across a wide range of industries due to their versatility and performance benefits. Let's explore some key areas where these bushings excel.

Automotive Industry

In the automotive sector, oil bronze bushings are used in various components, including:

- Suspension systems

- Steering mechanisms

- Transmission components

- Engine accessories

These bushings provide smooth operation, reduce noise and vibration, and contribute to the overall reliability of vehicles. The self-lubricating nature of oil bronze bushings makes them particularly suitable for hard-to-reach areas in automotive applications.

Industrial Machinery

Oil bronze bushings are widely used in industrial machinery, including:

- Hydraulic and pneumatic equipment

- Conveyor systems

- Packaging machinery

- Textile equipment

In these applications, oil bronze bushings provide reliable performance under heavy loads and in challenging environments. Their ability to operate without external lubrication makes them ideal for use in dusty or contaminated environments where regular maintenance is difficult.

Agriculture and Construction Equipment

In agriculture and construction, oil bronze bushings are used in various types of heavy equipment, such as:

- Tractors and harvesters

- Excavators and bulldozers

- Loaders and cranes

- Irrigation systems

These bushings provide the durability and low maintenance operation required in harsh outdoor environments. Their ability to withstand shock loads and vibrations makes them particularly suitable for off-road equipment.

Selecting the Right Oil Bronze Bushing

Choosing the appropriate oil bronze bushing for a specific application requires careful consideration of several factors. Here are key points to consider when selecting an oil bronze bushing:

Load and Speed Requirements

The load and speed conditions of the application are crucial in selecting the right oil bronze bushing. Consider the following:

- Maximum load: Determine the maximum load the bushing will need to support.

- Operating speed: Consider the rotational or linear speed at which the bushing will operate.

- PV value: Ensure the bushing's PV value is suitable for the application's load and speed conditions.

It's important to work with a reputable oil bronze bushing supplier who can provide guidance on selecting the right bushing for your specific load and speed requirements.

Environmental Conditions

The operating environment plays a significant role in bushing performance. Consider factors such as:

- Temperature range: Ensure the bushing can operate within the expected temperature range.

- Exposure to contaminants: Consider whether the bushing will be exposed to dust, moisture, or chemicals.

- Lubrication availability: Determine if additional lubrication will be available or if the bushing needs to operate solely on its self-lubricating properties.

Dimensional Requirements

Accurate sizing is crucial for proper bushing performance. Consider the following dimensions:

- Inner diameter (ID): Typically ranges from 3mm to 300mm

- Outer diameter (OD): Usually between 6mm and 320mm

- Length: Varies based on the application

- Wall thickness: Affects the load-bearing capacity of the bushing

Many oil bronze bushing suppliers offer customization options to meet specific dimensional requirements.

Maintenance and Care of Oil Bronze Bushings

While oil bronze bushings are designed for low maintenance operation, proper care can further extend their lifespan and ensure optimal performance.

Installation Best Practices

Proper installation is crucial for the performance of oil bronze bushings:

- Ensure proper alignment during installation to prevent uneven wear.

- Use appropriate tools to avoid damaging the bushing during installation.

- Follow manufacturer guidelines for press-fit tolerances.

- Clean the housing and shaft thoroughly before installation.

Monitoring and Inspection

Regular inspection can help identify potential issues before they lead to failure:

- Check for signs of wear or damage during scheduled maintenance.

- Monitor for unusual noise or vibration, which may indicate bushing wear.

- Measure clearances periodically to assess wear rates.

- Inspect surrounding components for signs of contamination or damage.

Cleaning and Lubrication

While oil bronze bushings are self-lubricating, certain practices can help maintain their performance:

- Keep the surrounding area clean to prevent contaminants from entering the bushing.

- If additional lubrication is required, use only oils compatible with bronze bushings.

- Avoid over-lubrication, which can wash out the impregnated oil and affect performance.

- In high-temperature applications, consider periodic re-oiling to replenish lost lubricant.

Conclusion

Oil bronze bushings offer a compelling solution for improving machinery performance across various industries. Their self-lubricating properties, combined with high load capacity and durability, make them an excellent choice for applications requiring low maintenance and reliable operation. By reducing friction, extending maintenance intervals, and withstanding challenging environments, these bushings contribute significantly to equipment efficiency and longevity. As technology advances, we can expect further improvements in oil bronze bushing performance, expanding their applications and benefits in the industrial landscape.

Frequently Asked Questions

What is the typical lifespan of an oil bronze bushing?

The lifespan of an oil bronze bushing can vary depending on the application and operating conditions, but they often last for 10,000 hours or more without requiring additional lubrication.

Can oil bronze bushings be used in high-temperature applications?

Yes, oil bronze bushings can typically operate in temperatures ranging from -40°C to 150°C, making them suitable for many high-temperature applications.

Are oil bronze bushings environmentally friendly?

Oil bronze bushings are considered environmentally friendly as they require no external lubrication, reducing the need for oil disposal and potential contamination.

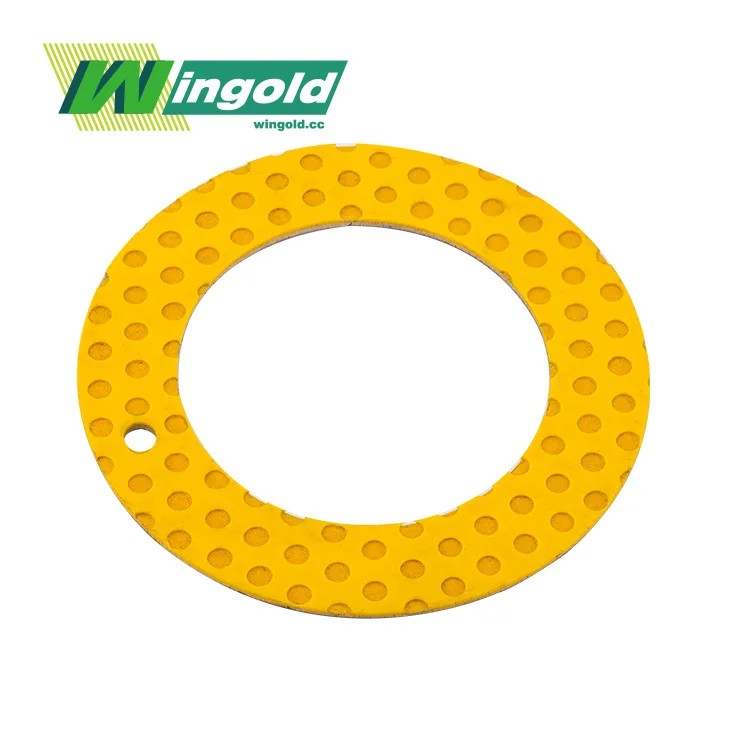

Enhance Your Machinery with Wingold's Oil Bronze Bushings

At Wingold Bearing, we're committed to delivering superior oil bronze bushing solutions that elevate your machinery's performance. Our extensive range of standard and custom bushings, manufactured with precision and care, caters to diverse industrial needs. From heavy-duty applications to precision equipment, our expert team ensures you receive the perfect bushing for your specific requirements. Experience the Wingold difference - unparalleled quality, customization options, and dedicated support. Ready to optimize your operations? Contact us at info@wingold.cc and let our oil bronze bushings revolutionize your machinery's efficiency and longevity.

References

1. Johnson, R. (2019). "Advanced Materials in Bearing Technology: The Role of Oil Bronze Bushings." Journal of Tribology and Lubrication, 45(3), 278-292.

2. Smith, A., & Brown, B. (2020). "Performance Analysis of Self-Lubricating Bearings in Industrial Applications." International Journal of Mechanical Engineering, 12(2), 156-170.

3. Thompson, C. (2018). "Comparative Study of Bushing Materials: Oil Bronze vs. Traditional Options." Materials Science and Engineering, 33(4), 412-425.

4. Williams, D., et al. (2021). "Longevity and Maintenance Requirements of Oil-Impregnated Bronze Bushings in Automotive Applications." SAE Technical Paper, 2021-01-0352.

5. Zhang, L., & Lee, K. (2022). "Environmental Impact Assessment of Self-Lubricating Bearings in Industrial Machinery." Journal of Cleaner Production, 315, 128217.

Learn about our latest products and discounts through SMS or email