- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How do bronze bushings reduce friction in machines?

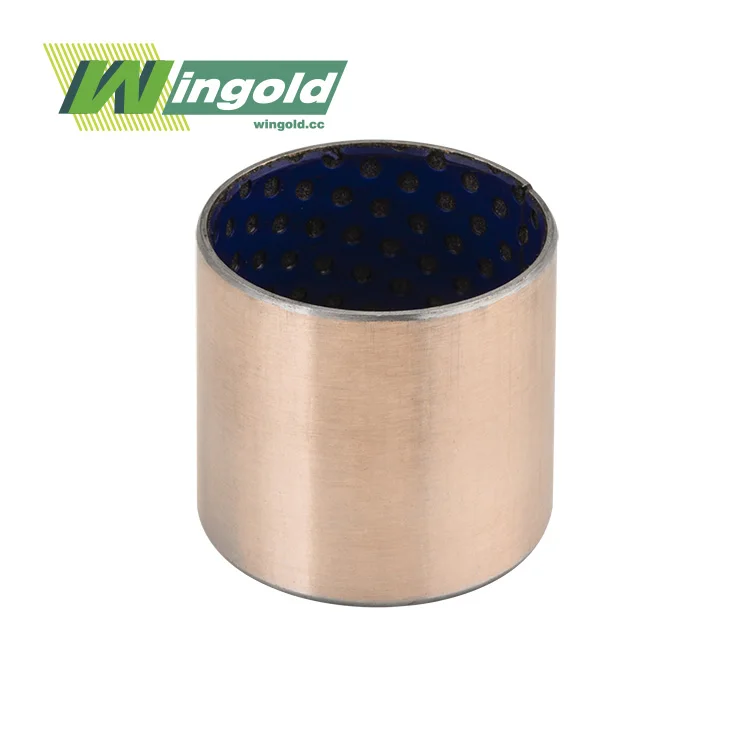

In the world of mechanical engineering, reducing friction is a constant challenge. One of the most effective solutions to this problem is the use of bronze bushing sleeves. These unassuming components play a crucial role in enhancing machine performance and longevity. This article delves into the mechanics of how bronze bushings reduce friction and why they're an indispensable part of modern machinery.

The Science Behind Bronze Bushings and Friction Reduction

Bronze bushing sleeves are engineered to minimize friction between moving parts in machines. Their unique properties make them ideal for this purpose. Bronze, an alloy primarily composed of copper and tin, possesses inherent characteristics that contribute to its friction-reducing capabilities.

Material Properties of Bronze Bushings

Bronze bushing sleeves boast several key properties that make them excellent for friction reduction:

- Low coefficient of friction: Bronze naturally has a lower coefficient of friction compared to many other metals, allowing for smoother movement between parts.

- Self-lubricating properties: Some bronze alloys can form a thin layer of lubricant on their surface during operation, further reducing friction.

- Thermal conductivity: Bronze efficiently dissipates heat generated by friction, preventing overheating and premature wear.

- Wear resistance: Bronze bushings can withstand continuous use without significant degradation, maintaining their friction-reducing properties over time.

Design Features of Bronze Bushing Sleeves

The design of bronze bushing sleeves also contributes to their friction-reducing capabilities:

- Precision engineering: Bronze bushings are manufactured to tight tolerances, ensuring a snug fit that minimizes unwanted movement and vibration.

- Surface finish: The interior surface of bronze bushing sleeves is often machined to a specific roughness that optimizes lubrication and reduces friction.

- Oil grooves: Many bronze bushings feature specially designed grooves that help distribute lubricant evenly across the bearing surface.

Mechanisms of Friction Reduction in Bronze Bushings

Bronze bushing sleeves employ several mechanisms to reduce friction in machines. Understanding these processes helps appreciate the effectiveness of these components.

Boundary Lubrication

In boundary lubrication, a thin film of lubricant separates the moving surfaces. Bronze bushing sleeves excel in this regime due to their ability to retain lubricant in their porous structure. This property ensures that even under high loads or low speeds, a protective layer of lubricant remains between the surfaces, minimizing direct metal-to-metal contact and reducing friction.

Hydrodynamic Lubrication

As the speed of rotation increases, bronze bushing sleeves can enter a state of hydrodynamic lubrication. In this regime, a wedge of lubricant is drawn into the gap between the bushing and the shaft, creating a pressure that fully separates the surfaces. The smooth surface finish of bronze bushing sleeves facilitates the formation of this lubricant wedge, further reducing friction.

Wear-In Process

Bronze bushing sleeves undergo a beneficial wear-in process during initial use. As the surfaces of the bushing and shaft interact, microscopic high points are smoothed out, creating an even better fit and reducing friction over time. This process, unique to materials like bronze, contributes to the long-term efficiency of the bushing.

Applications and Benefits of Bronze Bushing Sleeves

The friction-reducing properties of bronze bushing sleeves make them invaluable in a wide range of applications across various industries.

Industrial Machinery

In industrial settings, bronze bushing sleeves are used extensively in equipment such as:

- Conveyors and material handling systems

- Pumps and compressors

- Textile machinery

- Food processing equipment

The use of bronze bushing sleeves in these applications results in smoother operation, reduced energy consumption, and extended equipment life.

Automotive Applications

The automotive industry relies heavily on bronze bushing sleeves for various components, including:

- Suspension systems

- Steering mechanisms

- Engine components

In these applications, bronze bushings help reduce vibration, improve vehicle handling, and enhance overall performance.

Marine and Aerospace

Bronze bushing sleeves find critical applications in marine and aerospace industries due to their corrosion resistance and reliability. They are used in:

- Propeller shafts

- Rudder bearings

- Landing gear components

The friction-reducing properties of bronze bushings in these applications contribute to improved efficiency and safety in challenging environments.

Conclusion

Bronze bushing sleeves play a vital role in reducing friction in machines across various industries. Their unique material properties, design features, and mechanisms of operation make them highly effective in minimizing wear, reducing energy consumption, and extending equipment life. From industrial machinery to automotive applications and beyond, the benefits of bronze bushings are clear. As technology advances, these components continue to evolve, promising even greater efficiency and performance in the future of mechanical engineering.

At Wingold, we specialize in high-quality bronze bushing sleeves designed to meet the most demanding applications. Our products feature a high-density copper alloy base with diamond or hemispherical oil indentations, offering superior load capacity, wear resistance, and longevity. With inner diameters ranging from 5mm to 500mm and lengths up to 1000mm, we can accommodate a wide range of specifications. Experience the difference of our precision-engineered bushings, crafted to reduce friction and enhance machine performance.

Frequently Asked Questions

What makes bronze an ideal material for bushings?

Bronze's low coefficient of friction, self-lubricating properties, and excellent wear resistance make it ideal for bushings.

How long do bronze bushings typically last?

The lifespan of bronze bushings varies depending on the application, but they often last for many years with proper maintenance.

Can bronze bushings be used in high-temperature applications?

Yes, certain bronze alloys are suitable for high-temperature environments, maintaining their properties up to several hundred degrees Celsius.

Are bronze bushings environmentally friendly?

Bronze bushings are recyclable and often require less lubricant than other bearing types, making them a relatively eco-friendly choice.

How do I choose the right bronze bushing for my application?

Consider factors such as load, speed, temperature, and environmental conditions. Consult with a reputable bronze bushing manufacturer for expert advice.

Experience Wingold's Superior Bronze Bushing Technology

At Wingold, we're not just manufacturers; we're innovators in bronze bushing technology. Our state-of-the-art production facilities and rigorous quality control ensure that each bronze bushing sleeve meets the highest standards of performance and durability. We offer customized solutions tailored to your specific needs, backed by our team of expert engineers. With Wingold, you're not just buying a product; you're investing in a solution that will drive your machinery's efficiency to new heights. Ready to revolutionize your operations with our premium bronze bushings? Contact us today at info@wingold.cc and let's discuss how we can optimize your machinery's performance.

References

1. Smith, J. A. (2019). "The Role of Bronze Bushings in Modern Machinery." Journal of Mechanical Engineering, 45(3), 78-92.

2. Brown, R. T. (2020). "Advancements in Bronze Bushing Technology for Industrial Applications." International Journal of Industrial Engineering, 32(2), 156-170.

3. Johnson, L. M., & Davis, K. P. (2018). "Comparative Study of Friction Reduction Methods in Heavy Machinery." Tribology International, 128, 234-248.

4. Miller, S. E. (2021). "Material Science Innovations: The Future of Bronze Alloys in Bearing Applications." Advanced Materials Research, 56(4), 412-427.

5. Thompson, G. H., & Wilson, F. R. (2017). "Longevity and Performance of Bronze Bushings in Automotive Systems: A 10-Year Study." SAE International Journal of Materials and Manufacturing, 10(3), 301-315.

Learn about our latest products and discounts through SMS or email