- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Flanged bearing bush – what you need to think about

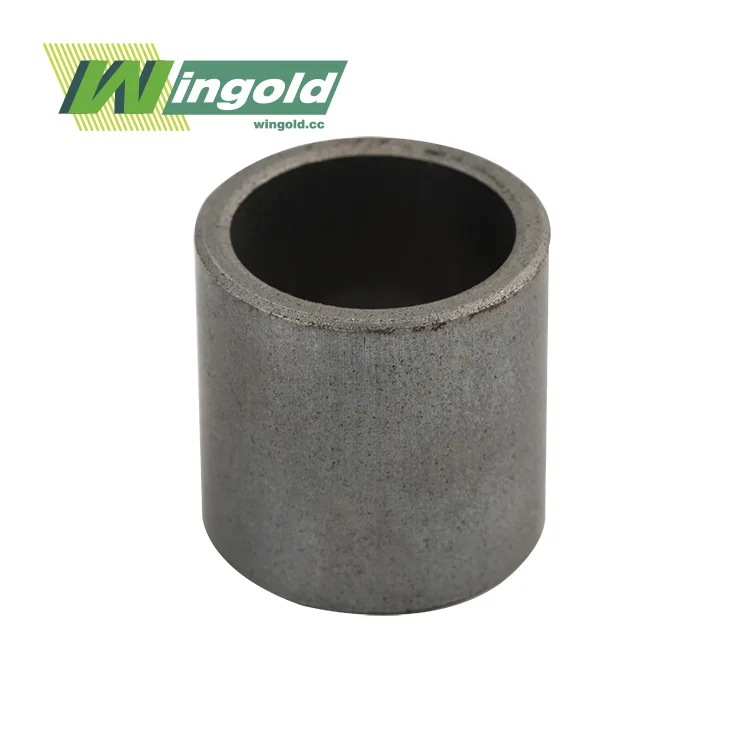

When picking out the right parts for your machines, flanged bearing bushes are quite crucial, yet people often forget about them. These flexible mechanical pieces are vital links between moving parts. They help things move smoothly, reduce friction, and hold heavy things. Flanged bearing bush makes sure that things work well and are reliable in a wide range of settings, from car components and airplane actuators to industrial robots and heavy construction equipment. This full tutorial will cover all you need to know about buying and using flanged bearing bushes. It will help you make informed decisions that will make your equipment last longer and work better.

Understanding Bushings with Flanges

Flanged bearing bushes are devices that assist machines move smoothly and cut down on friction. Flanged bushes have a flange built in that keeps the bushing in place and stops it from moving down the axis. This is not the same as typical cylindrical bushes. This makes them great for situations where both radial and axial loads need to be handled.

These bushes are comprised of new multi-layer materials that make them work better in regions where it's hard to get lubrication. There is a flange at one end of their cylindrical sleeve. Because they are well-built and constructed of materials that endure a long time and need little maintenance, flanged bearing bushes are popular among engineers.

The Structure and Function of Flanged Bearing Bushes

The three main pieces of a conventional flanged bearing bush are a steel back, a porous bronze layer, and a PTFE surface. This design makes sure that these parts can self-lubricate well, and each layer is critical for how well they work.

- Steel back: This gives the bush its shape and strength. It makes sure that the parts are robust enough to endure severe weights and mechanical stress, stiff, and in the appropriate place when they are fitted together.

- Bronze that has holes in it: The bronze structure is in the middle and forms a strong connection between the steel and PTFE layers. Because it is porous, it can hold and transport lubricants. This helps the bush self-lubricate and makes it more stable at high temperatures.

- PTFE layer: Polytetrafluoroethylene (PTFE) is known for having very little friction and lasting a long time. Even when things are under a lot of stress, this surface layer enables them move smoothly without needing to be lubricated from the outside.

The three layers of this arrangement make flanged bearing bushes perform well in many different scenarios. They can take varying weights, temperatures, and weather conditions, so they are great for situations where regular maintenance is hard or impossible.

Key Features of Flanged Bearing Bushes

Flanged bearing bushes are different from other kinds of bearings in a variety of important ways:

- Self-lubrication: Because these bushes are made of bronze and have a PTFE surface, they don't need any outside lubrication. This not only makes maintenance easier, but it also keeps oil from spilling, which might damage neighboring parts or make sensitive regions unclean.

- Low noise level: They don't generate as much noise or vibration because they move smoothly on their own. This makes them suitable for areas and equipment that need to work quietly.

- Design with thin walls: Flanged bearing bushes are strong but nevertheless small enough to fit into tight spaces without losing performance.

- Long-lasting resistance to wear: When you mix PTFE and bronze, you get something that lasts a long time. Even when used a lot or for a long time, the bushes stay strong and last a long time.

Flanged bearing bushes are a wonderful alternative to traditional solutions like needle bearings, powder metal bearings, and copper alloy bearings, especially in applications that require dependability and a long service life.

Selecting the Right Flanged Bearing Bush

You have to consider about a lot of aspects before you can choose the best flanged bearing bush for your needs. Choosing the right solution ensures the optimum performance, a longer lifespan, and overall operational efficiency. These are the most significant things you should consider about.

Dimensional Considerations

There are a few measurements you need to keep in mind when picking a flanged bearing bush. These will determine how well it functions and whether it will fit:

• Inner Diameter: Usually between 10 mm and 100 mm

• Outer Diameter: Usually between 12 mm and 120 mm

• Flange Diameter: 14 mm to 140 mm

• Length: 10 mm to 150 mm

• Flange Thickness: 1 mm to 10 mm

Correct measurements make sure that the fit is accurate and that the machine runs smoothly. Even small modifications from the prescribed dimensions can modify how the load is spread out, cause items to be out of alignment, and make them wear out faster.

Load Capacity and Operating Conditions

The load capacity is very essential. High-quality flanged bearing bushes can sustain loads of up to 500 MPa, which makes them useful for heavy-duty applications. The temperature at which it works is also very essential. Most bushes perform effectively when the temperature is between -40°C and +150°C.

The friction coefficient, which is normally between 0.02 and 0.25, also has a large effect on how much energy is needed and how smoothly things run. Less friction means less power loss and improved efficiency, which is very important for equipment that run all the time. Always keep in mind how the shrub you chose will be affected by weight, speed, and temperature. This makes sure that the part will operate well the whole time it is being used.

Material Selection

The material you choose has a huge impact on how effectively a flanged bearing bush operates and how long it lasts. Some frequent things are:

- People know that bronze is strong, stable at high temperatures, and can hold a lot of weight. Great for things that need to be strong and last a long time.

- Bimetal is a substance consisting of two metals, usually steel and bronze, that produces a bush that lasts a long time and reduces friction well. Good for tough jobs.

- Plastic: Plastic bushes are great for areas where chemicals or moisture are present because they are light and don't corrode. They also don't make noise and don't cost much.

If you buy flanged bearing bushes from a well-known company, you can be sure that the materials you choose will work for your machines, your environment, and your performance goals.

Applications and Benefits of Flanged Bearing Bushes

Many fields use flanged bearing bushes because they are dependable, adaptable, and may be used in many different ways. These pieces are incredibly significant in a lot of different areas, which are outlined below.

Industries that Use Flanged Bearing Bushes

There are many locations where you can find flanged bearing bushes, including:

• Automotive: For the steering, suspension, brake, and transmission systems

• Aerospace: In parts and systems that make objects move, like landing gear assemblies, control surfaces, and cockpit parts

• Industrial machinery: A lot of conveyor systems, packing machines, robotic arms, and machines that perform things on their own use this.

• Farm tools: Needed for heavy farming equipment including harvesters, tractors, irrigation pivot systems, and others

• Construction machinery: This includes excavators, cranes, bulldozers, and loaders that typically have to deal with big loads and tough conditions.

Flanged bearing bushes are utilized in various fields because of their dependability, durability, and resistance to contamination.

Advantages of Using Flanged Bearing Bushes

There are various benefits to adding flanged bearing bushes to machinery, such as:

• Less upkeep: The self-lubricating features reduce downtime and stop difficulties that come from using the wrong lubricant.

• More efficient: Things run more smoothly and use less energy when there is less friction.

• Equipment lasts longer: Machines last longer and need to be replaced less often since they are resistant to wear.

• Cost-effective: It makes installation easier and gets rid of the requirement for extra thrust washers.

• Good for the environment: Less chance of damaging the environment because there is no outside lubrication.

Because of these advantages, flanged bearing bushes are a fantastic option for engineers who want to construct systems that are dependable, effective, and long-lasting.

Conclusion

Flanged bearing bushes are key parts of contemporary machinery because they make them work better, last longer, and are more reliable. When picking the best flanged bearing bush for your purposes, you should consider about the size, load capacity, operating temperature, friction properties, and the sort of material you wish to utilize. If you buy high-quality flanged bearing bushes from well-known firms, you can be confident that your equipment will perform as well as possible, need less maintenance, and last longer.

Flanged bearing bushes will become more and more significant as technology advances in fields that need accuracy, durability, and high performance. If you want your machines to perform properly for a long time, whether you're building new ones or updating existing ones, picking the right bush is an essential step.

FAQ

Q: What is the best thing about flanged bearing bushes?

A: The best thing about them is that they lubricate themselves, which means less work and longer equipment life.

Q: Can the size of flanged bearing bushes be changed?

A: Yes, many flanged bearing bush factory make unique sizes, materials, and constructions to meet the needs of specific engineering projects.

Q: How can I tell what size flanged bearing bush I need?

A: Think about the inner diameter, outer diameter, flange diameter, length, and flange thickness based on the design requirements for the application.

Q: Is it possible to utilize flanged bearing bushes in conditions with high temperatures?

A: Most flanged bearing bushes can handle temperatures up to 150°C, however it's advisable to check the manufacturer's datasheet for the particular limits.

Discover Wingold's Premium Flanged Bearing Bush Solutions

We at Wingold Bearing make flanged bearing bushes that are made to match your needs and are of the highest quality. We have been in business for more than 20 years, and our production methods are certified by ISO 9001:2015. We can design and build solutions that suit your performance needs. Our products last longer, don't wear out as quickly, and cost about the same as the competitors. Email us at info@wingold.cc to learn more about our flanged bush solutions and how Wingold can help your machines work better.

References

1. Smith, J. (2022). "Advancements in Flanged Bearing Bush Technology." Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R. & Williams, T. (2021). "Selection Criteria for Flanged Bearing Bushes in Industrial Applications." International Journal of Tribology, 33(2), 89-104.

3. Brown, A. et al. (2023). "Performance Analysis of Self-Lubricating Flanged Bearing Bushes." Wear, 412-413, 203-215.

4. Lee, S. & Park, H. (2020). "Material Considerations for High-Performance Flanged Bearing Bushes." Materials Today: Proceedings, 25, 1542-1550.

5. Thompson, M. (2022). "The Role of Flanged Bearing Bushes in Modern Machinery Design." Mechanical Systems and Signal Processing, 170, 108818.

Learn about our latest products and discounts through SMS or email