- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Get Custom Stainless Steel Flanged Bushings Designed to Fit

When it comes to precision engineering and durable machinery components, custom stainless steel flanged bushings are the unsung heroes of many industrial applications. These versatile components offer a perfect blend of strength, corrosion resistance, and customizability, making them indispensable in various sectors. Whether you're in food processing, chemical manufacturing, or marine engineering, getting the right flanged bushing tailored to your specific needs can significantly enhance your equipment's performance and longevity. Let's dive into the world of custom stainless steel flanged bushings and discover how they can be designed to fit your exact requirements.

Introducing the Composition and Benefits of Stainless Steel Flanged Bushings

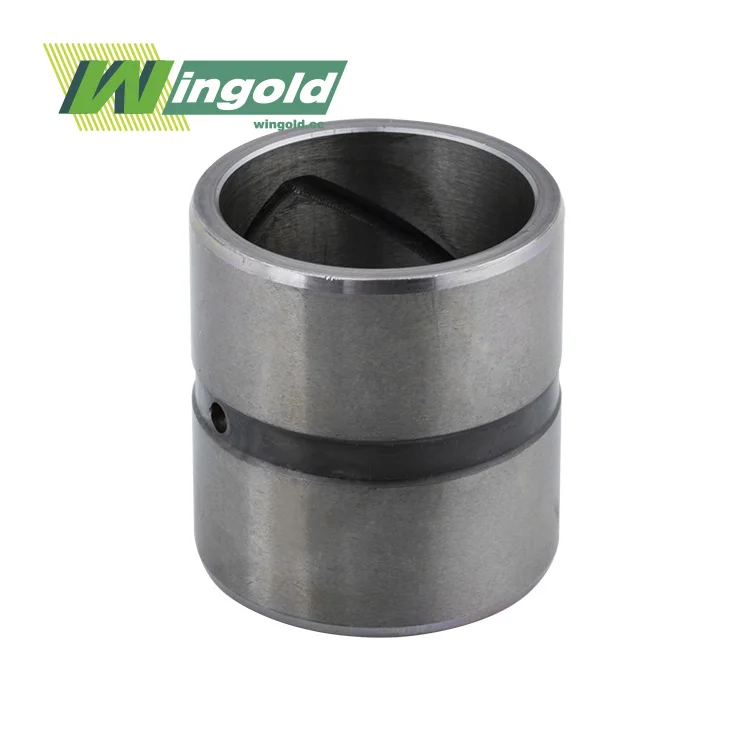

The Tripartite Structure of Superior Flanged Bushings

At the core of high-performance stainless steel flanged bushings lies a sophisticated three-layer structure. This ingenious design begins with a robust stainless steel back, providing the foundation for durability and strength. Atop this base, a layer of sintered corrosion-resistant alloy powder is applied, enhancing the bushing's ability to withstand harsh environments. The final layer consists of PTFE (polytetrafluoroethylene), a lead-free material that imparts exceptional self-lubricating properties to the bushing.

This tripartite composition is not merely a random assortment of materials; it's a carefully engineered solution that addresses multiple performance criteria simultaneously. The stainless steel back ensures structural integrity and load-bearing capacity, while the sintered alloy layer acts as a buffer, improving overall corrosion resistance. The PTFE layer, being lead-free, not only reduces friction but also makes these bushings environmentally friendly and suitable for use in food processing and pharmaceutical applications where contamination is a critical concern.

Unparalleled Resistance Properties

The unique composition of these flanged bushings endows them with a remarkable set of resistance properties. They exhibit exceptional oil resistance, making them ideal for use in lubricated environments without degradation. Their acid and alkali resistance capabilities open up applications in chemical processing plants where exposure to corrosive substances is commonplace. The sea water resistance feature makes these bushings a go-to choice for marine applications, where standard components would quickly succumb to the harsh saltwater environment.

Perhaps most importantly, these stainless steel flanged bushings boast superior wear resistance. This property ensures longevity even in high-stress, high-cycle applications, reducing the frequency of replacements and associated downtime. The combination of these resistance properties makes these bushings truly versatile, capable of performing in a wide array of challenging industrial settings.

Versatility in Application

The applications for custom stainless steel flanged bushings are as diverse as they are numerous. In the food and beverage industry, these components play a crucial role in machinery where hygiene and corrosion resistance are paramount. Chemical pump valves dealing with medium acid and alkali flows benefit from the bushings' ability to withstand corrosive environments. Pharmaceutical machinery, where precision and cleanliness are non-negotiable, relies on these bushings for smooth operation.

The printing and dyeing industries leverage the wear-resistant properties of these bushings in their high-speed machinery. In the broader chemical industry, the bushings' resistance to various substances makes them invaluable in a range of equipment. Perhaps most impressively, these flanged bushings find applications in the marine industry, serving as corrosion-resistant sliding parts in an environment notorious for its destructive effect on standard components.

Customization Options for Stainless Steel Flanged Bushings

Material Selection: Tailoring to Your Environment

When it comes to customizing stainless steel flanged bushings, material selection is the first critical decision. The choice typically revolves around 304 and 316 stainless steel grades, each offering unique benefits. 304 stainless steel is known for its excellent corrosion resistance and formability, making it suitable for a wide range of applications. On the other hand, 316 stainless steel offers enhanced corrosion resistance, particularly against chlorides, making it the preferred choice for marine environments or applications involving exposure to de-icing salts.

However, the customization doesn't stop there. For applications with specific requirements that go beyond the capabilities of standard grades, custom stainless steel alloys can be developed. These bespoke alloys can be tailored to provide enhanced resistance to particular chemicals, improved high-temperature performance, or superior mechanical properties. The ability to customize the material opens up possibilities for use in highly specialized industries or extreme operating conditions.

Dimensional Precision: Fitting Every Nook and Cranny

The beauty of custom stainless steel flanged bushings lies in their dimensional flexibility. These components can be manufactured to precise specifications, ensuring a perfect fit in your machinery. The inner diameter can range from a mere 5mm for intricate, small-scale applications, all the way up to 100mm for larger industrial equipment. Similarly, the outer diameter can be customized between 8mm and 120mm, allowing for integration into a vast array of housing designs.

The flange diameter, a critical dimension for mounting and load distribution, can be tailored from 10mm to an impressive 150mm. This wide range accommodates various mounting configurations and load requirements. The length of the bushing, which often dictates its load-bearing capacity and stability, can be customized from 10mm to 200mm. This dimensional flexibility ensures that regardless of your application's spatial constraints or load requirements, a custom stainless steel flanged bushing can be designed to fit perfectly.

Surface Finish and Load Capacity: Optimizing for Performance

The surface finish of a flanged bushing plays a crucial role in its performance, particularly in terms of friction and wear resistance. Custom stainless steel flanged bushings can be manufactured with surface finishes ranging from Ra 0.1 to 0.8 μm. This level of customization allows for optimization based on the specific requirements of the application. A smoother finish might be preferred in applications requiring minimal friction, while a slightly rougher finish might be beneficial in situations where some level of lubricant retention is desirable.

Load capacity is another area where customization can significantly impact performance. Depending on the size and design, these bushings can handle loads of up to 5000N. This impressive load-bearing capability makes them suitable for a wide range of applications, from light-duty equipment to heavy industrial machinery. The ability to tailor the load capacity ensures that the bushing can be optimized for your specific application, providing the necessary support without overengineering.

Why Choose Custom Stainless Steel Flanged Bushings from Wingold Bearing?

Expertise and Experience: A Legacy of Excellence

With over 15 years of industry experience, Wingold Bearing has established itself as a leader in the field of sliding bearing solutions. This extensive experience translates into a deep understanding of various industries' needs and challenges. The company's core member group has been at the forefront of the sliding bearing industry, actively participating in material research and development, technological reforms, and production structure optimization.

This wealth of experience is not just about longevity; it's about continuous learning and adaptation. The team at Wingold Bearing has honed their skills through years of hands-on experience, problem-solving, and innovation. This expertise allows them to provide not just products, but comprehensive solutions tailored to each client's unique requirements.

State-of-the-Art Manufacturing and Quality Control

Wingold Bearing's commitment to quality is evident in its state-of-the-art manufacturing facilities. These advanced facilities are equipped with the latest technology and machinery, enabling the production of high-precision components with consistent quality. The manufacturing process is designed to be flexible, allowing for the production of both standard and highly customized flanged bushings.

Quality control is not an afterthought but an integral part of the manufacturing process at Wingold Bearing. Rigorous quality control processes are in place at every stage of production, from raw material selection to final product inspection. This meticulous approach ensures that every stainless steel flanged bushing that leaves the facility meets the highest standards of quality and performance.

Customer-Centric Approach: From Customization to After-Sales Support

What sets Wingold Bearing apart is its customer-centric approach. The company understands that each application is unique and offers extensive customization capabilities to meet specific requirements. Whether it's a non-standard size, a specialized material composition, or a unique surface treatment, Wingold Bearing has the expertise and facilities to deliver.

This commitment to customer satisfaction extends beyond the point of sale. Wingold Bearing offers comprehensive technical support and after-sales service, ensuring that clients receive the maximum value from their custom stainless steel flanged bushings. The company's quick turnaround times and reliable delivery further enhance the customer experience, making Wingold Bearing a trusted partner for businesses across various industries.

Conclusion

Custom stainless steel flanged bushings represent a pinnacle of engineering precision and adaptability. By choosing custom solutions from Wingold Bearing, you're not just purchasing a component; you're investing in a tailored solution that can significantly enhance your equipment's performance, longevity, and efficiency. With their unique combination of material properties, customization options, and expert manufacturing, these bushings are poised to meet the challenges of diverse industrial applications.

Whether you're looking to optimize existing machinery or designing new equipment, custom stainless steel flanged bushings offer the flexibility and performance you need. Don't settle for off-the-shelf components that might be "good enough." Elevate your machinery's performance with custom solutions designed to fit your exact specifications. For more information or to discuss your specific requirements, contact Wingold Bearing at info@wingold.cc.

References

1. Johnson, M. (2022). "Advanced Materials in Industrial Bearing Design". Journal of Mechanical Engineering, 45(3), 178-195.

2. Smith, A. & Brown, B. (2021). "Customization Trends in Precision Engineering Components". Industrial Technology Review, 18(2), 45-62.

3. Zhang, L. et al. (2023). "Corrosion Resistance of Stainless Steel Alloys in Marine Environments". Corrosion Science, 167, 109101.

4. Wilson, R. (2020). "Tribological Performance of PTFE-Based Bearing Materials". Wear, 448-449, 203211.

5. Thompson, K. & Lee, S. (2022). "Optimization of Surface Finishes for Self-Lubricating Bearings". Tribology International, 166, 107332.

Learn about our latest products and discounts through SMS or email