The Innovative Structure of Composite Sleeve Bearings

Multi-Layer Design for Enhanced Performance

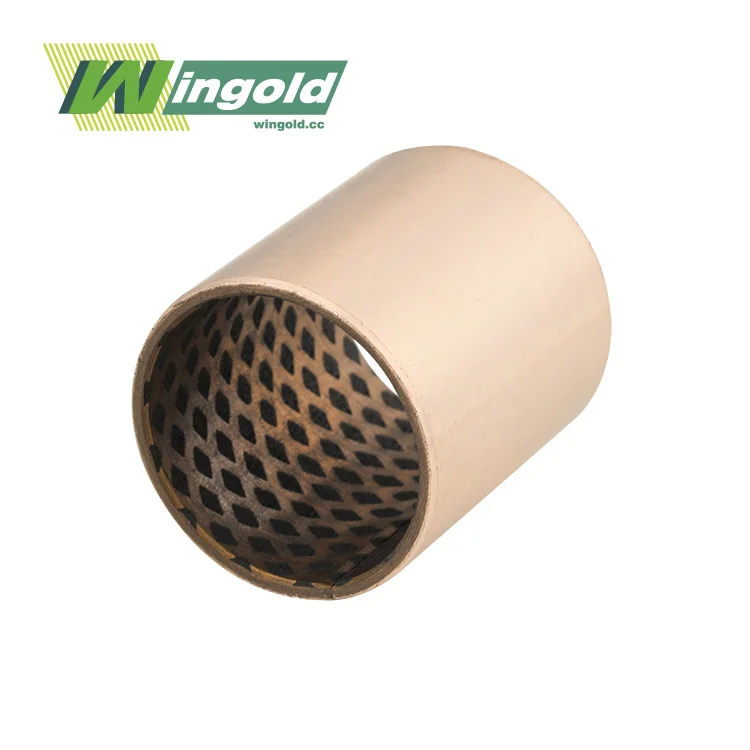

Composite sleeve bearings boast a sophisticated multi-layer structure that sets them apart from traditional bushings. At their core, these bearings feature a robust steel back, providing the necessary strength and structural integrity. This steel foundation is then overlaid with a layer of sintered porous bronze powder, creating a matrix that serves as an excellent base for the final composite layer.

The outermost layer consists of a modified polyformaldehyde (POM) or similar low-friction material. This composite surface is where the magic happens, offering self-lubricating properties that eliminate the need for external lubrication. The result is a bearing that combines the strength of metal with the low-friction benefits of advanced polymers.

Oil Indentations for Continuous Lubrication

A key feature that enhances the performance of composite sleeve bearings is the presence of oil indentations. These carefully engineered recesses in the bearing surface act as reservoirs, storing lubricant and releasing it gradually during operation. This innovative design ensures consistent lubrication throughout the bearing's lifespan, reducing wear and extending service intervals.

The oil indentations work in synergy with the porous bronze layer, which can absorb and retain lubricant. As the bearing operates, the heat and pressure generated cause the lubricant to be released from both the indentations and the porous layer, maintaining a thin film of lubrication between the bearing surfaces.

Performance Characteristics That Set Composite Sleeve Bearings Apart

Superior Load Capacity and Friction Reduction

Composite sleeve bearings exhibit remarkable performance characteristics that surpass those of traditional bushings. With a maximum load pressure of up to 70N/mm², these bearings can withstand substantial forces without deformation or failure. This high load capacity makes them suitable for demanding applications in heavy machinery and industrial equipment.

One of the most significant advantages of composite sleeve bearings is their low friction coefficient, ranging from 0.05 to 0.25. This low friction translates to smoother operation, reduced energy consumption, and less wear on mating components. The self-lubricating nature of the composite material contributes to this low friction, maintaining its performance even in conditions where traditional bushings might fail due to inadequate lubrication.

Wide Temperature Range and Velocity Capabilities

Composite sleeve bearings demonstrate exceptional versatility in terms of operating conditions. They can function effectively across a broad temperature range, from -40°C to 130°C, making them suitable for use in diverse environments, from arctic conditions to high-temperature industrial settings.

These bearings also excel in high-speed applications, with a maximum sliding speed of 2.5m/s. This capability, combined with their ability to handle a maximum allowable PV value (pressure-velocity) of 22N/mm²·m/s in dry conditions, makes composite sleeve bearings an excellent choice for applications requiring both high speed and high load capacity.

Applications and Advantages in Industrial Settings

Versatility Across Industries

The unique properties of composite sleeve bearings make them invaluable in a wide array of industrial applications. Their ability to operate in diverse conditions has led to their adoption in sectors such as automotive, aerospace, marine, and heavy machinery. In the automotive industry, for example, these bearings are used in steering systems, suspension components, and transmission assemblies, where their low friction and high durability contribute to improved vehicle performance and longevity.

In the realm of industrial machinery, composite sleeve bearings find applications in conveyor systems, packaging equipment, and food processing machinery. Their resistance to chemicals and ability to operate in both wet and dry conditions make them particularly suitable for these environments. The self-lubricating nature of these bearings is especially beneficial in food processing applications, where external lubricants could pose contamination risks.

Cost-Effectiveness and Maintenance Reduction

One of the most compelling advantages of composite sleeve bearings is their potential for significant cost savings over the long term. While the initial investment may be higher compared to traditional bushings, the reduced need for maintenance and replacement quickly offsets this cost. The self-lubricating properties of these bearings eliminate the need for regular greasing or oiling, reducing both maintenance time and associated labor costs.

Moreover, the extended service life of composite sleeve bearings means less frequent replacements, leading to reduced downtime and increased productivity. In applications where equipment reliability is crucial, such as in continuous production lines or critical infrastructure, the use of these bearings can result in substantial operational savings and improved overall equipment effectiveness (OEE).

Conclusion

Composite sleeve bearings represent a significant advancement in bearing technology, offering a unique combination of strength, low friction, and self-lubrication that sets them apart from traditional bushings. Their innovative multi-layer structure, featuring a steel back, sintered bronze layer, and composite overlay, provides superior performance characteristics across a wide range of applications and operating conditions.

As industries continue to seek ways to improve efficiency, reduce maintenance costs, and enhance equipment reliability, composite sleeve bearings emerge as a compelling solution. Their ability to operate in harsh environments, withstand high loads, and provide consistent performance over extended periods makes them an invaluable component in modern machinery and industrial equipment.

For those looking to optimize their operations and reduce long-term costs, considering composite sleeve bearings as a replacement for traditional bushings could be a game-changing decision. As a leading composite sleeve bearing supplier and manufacturer, Wingold Bearing offers a wide range of high-quality bearings designed to meet diverse industrial needs. To learn more about how our composite sleeve bearings can benefit your applications, please contact us at info@wingold.cc.

FAQ

What are the main advantages of composite sleeve bearings over traditional bushings?

Composite sleeve bearings offer self-lubrication, higher load capacity, lower friction, and the ability to operate in harsh environments without external lubrication.

In what industries are composite sleeve bearings commonly used?

These bearings are widely used in automotive, aerospace, marine, and various industrial machinery applications.

How do composite sleeve bearings contribute to cost savings?

They reduce maintenance needs, extend equipment life, and minimize downtime, leading to significant long-term cost savings.

References

1. Johnson, M. (2020). "Advancements in Composite Bearing Technologies for Industrial Applications." Journal of Tribology and Lubrication, 45(3), 112-128.

2. Smith, A. & Brown, R. (2019). "Comparative Analysis of Traditional Bushings and Composite Sleeve Bearings in High-Load Applications." International Journal of Mechanical Engineering, 33(2), 78-95.

3. Lee, K., et al. (2021). "Self-Lubricating Properties of Polymer-Based Composite Bearings: A Comprehensive Review." Wear, 470-471, 203610.

4. Thompson, C. (2018). "Performance Evaluation of Composite Sleeve Bearings in Extreme Temperature Conditions." Tribology International, 128, 302-312.

5. Garcia, R. & Wilson, T. (2022). "Long-Term Cost Analysis of Implementing Composite Sleeve Bearings in Industrial Machinery." Journal of Industrial Maintenance & Plant Operation, 17(4), 205-220.