The Advantages of Brass Thrust Washers in Industrial Applications

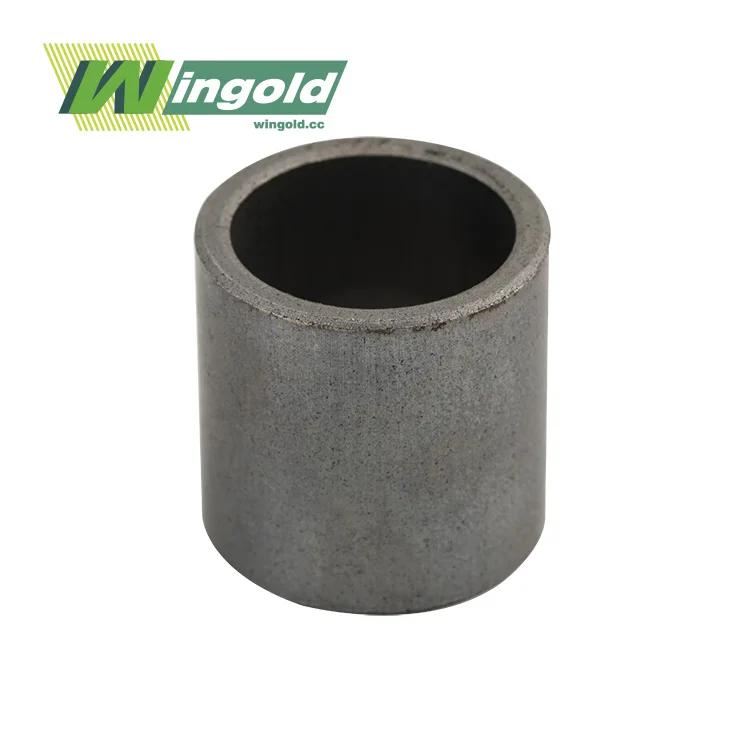

Brass thrust washers, particularly the 4 mm id brass thrust washer, have gained popularity in various industrial sectors due to their unique properties. These precision-engineered components offer a multitude of benefits that make them indispensable in many applications.

Superior Friction Reduction

One of the primary advantages of brass thrust washers is their ability to significantly reduce friction between moving parts. The inherent properties of brass allow for smooth sliding motion, which is crucial in applications where minimal wear and energy loss are desired. This characteristic makes brass thrust washers particularly useful in machinery that requires frequent starts and stops or continuous operation.

Corrosion Resistance

Brass thrust washers exhibit excellent resistance to corrosion, outperforming many other materials in this aspect. This property is especially valuable in environments where exposure to moisture, chemicals, or other corrosive elements is common. The 4 mm id brass thrust washer can maintain its integrity and performance even in challenging conditions, ensuring longevity and reliability of the equipment it's used in.

Thermal Conductivity

Another significant advantage of brass thrust washers is their high thermal conductivity. This property allows for efficient heat dissipation, which is crucial in applications where temperature management is essential. By effectively distributing heat, brass thrust washers help prevent localized overheating and potential damage to surrounding components, contributing to the overall efficiency and lifespan of the machinery.

Comparing Brass and Steel Thrust Washers: A Comprehensive Analysis

While both brass and steel thrust washers provide reliable functionality, a closer examination highlights why brass is frequently selected over steel in many engineering contexts. Brass offers a balance of mechanical strength, wear resistance, and natural lubricity, making it highly versatile across different industries. Steel, by contrast, excels in strength and rigidity but often requires additional treatments or lubrication. This fundamental difference helps explain why brass thrust washers are often considered the more practical and adaptable choice.

Load-Bearing Capacity

Steel thrust washers typically demonstrate higher load-bearing capacity due to their greater hardness and rigidity, making them suitable for extremely heavy-duty environments. Nevertheless, the 4 mm ID brass thrust washer remains capable of managing substantial loads when properly designed and dimensioned. By distributing forces evenly across its surface, brass can achieve reliable performance even under challenging operating conditions. When appropriately integrated into a system, brass thrust washers can sustain demanding loads while preserving functionality and preventing premature mechanical failures.

Wear Resistance

Brass thrust washers are renowned for their impressive wear resistance, often surpassing the performance of steel in applications involving continuous motion and friction. The inherent self-lubricating qualities of brass help reduce direct metal-to-metal contact, thereby minimizing surface degradation. This translates into a longer operational lifespan and fewer interruptions for maintenance. Particularly in systems where downtime is expensive or difficult to manage, the wear-resistant nature of brass provides a crucial advantage, ensuring stability and long-term reliability in critical operations.

Cost-Effectiveness

Although the upfront investment for brass thrust washers may appear higher than steel alternatives, their overall value becomes evident in long-term use. The durability, reduced maintenance requirements, and superior performance contribute to extended service life and lower replacement frequency. These benefits collectively result in notable cost savings over the lifespan of equipment. For businesses seeking both operational efficiency and economic advantages, brass thrust washers often represent the more sustainable and cost-effective solution, balancing initial expense with long-term return on investment.

Applications and Industries Benefiting from 4 mm id Brass Thrust Washers

The versatility and performance advantages of brass thrust washers make them suitable for a wide range of industries and applications.

Automotive Industry

In the automotive sector, 4 mm id brass thrust washers find extensive use in various components such as transmissions, steering systems, and suspension assemblies. Their ability to reduce friction and withstand high temperatures makes them ideal for these demanding applications.

Aerospace Engineering

The aerospace industry relies heavily on high-performance components, and brass thrust washers play a crucial role in many aircraft systems. From landing gear mechanisms to control surfaces, these washers contribute to the smooth and reliable operation of critical components.

Industrial Machinery

Various types of industrial machinery benefit from the use of brass thrust washers. These include conveyor systems, packaging equipment, and manufacturing robots. The durability and low maintenance requirements of brass thrust washers make them particularly valuable in continuous operation scenarios.

Marine Applications

The corrosion-resistant properties of brass thrust washers make them an excellent choice for marine applications. They are commonly used in boat propeller systems, rudder assemblies, and various shipboard machinery where exposure to saltwater is a constant concern.

Conclusion

In conclusion, while both brass and steel thrust washers have their place in various applications, the unique properties of brass often make it the superior choice. The 4 mm id brass thrust washer, with its excellent friction reduction, corrosion resistance, and thermal conductivity, offers significant advantages in a wide range of industries. From automotive and aerospace to industrial machinery and marine applications, brass thrust washers continue to prove their worth as essential components in modern engineering.

If you're looking for high-quality brass thrust washers or need expert advice on selecting the right components for your application, don't hesitate to reach out to us at info@wingold.cc. As a leading thrust washer manufacturer and supplier, we're committed to providing top-notch products and personalized solutions to meet your specific needs.

FAQ

What are the main advantages of using a 4 mm id brass thrust washer?

The main advantages include superior friction reduction, excellent corrosion resistance, high thermal conductivity, and long service life.

Can brass thrust washers be used in high-temperature applications?

Yes, brass thrust washers perform well in high-temperature environments due to their excellent thermal conductivity and stability.

Are brass thrust washers suitable for use in wet or humid conditions?

Absolutely. The corrosion-resistant properties of brass make these washers ideal for use in wet or humid conditions.

How do I choose the right size thrust washer for my application?

The choice depends on factors like shaft diameter, load requirements, and space constraints. It's best to consult with a thrust washer supplier for expert advice.

Can brass thrust washers be custom-made for specific applications?

Yes, many manufacturers offer custom-made brass thrust washers to meet specific application requirements.