Understanding Oil Pump Bushings and Their Function

Understanding Oil Pump Bushings and Their Function

The Role of Oil Pump Bushings in Pump Operation

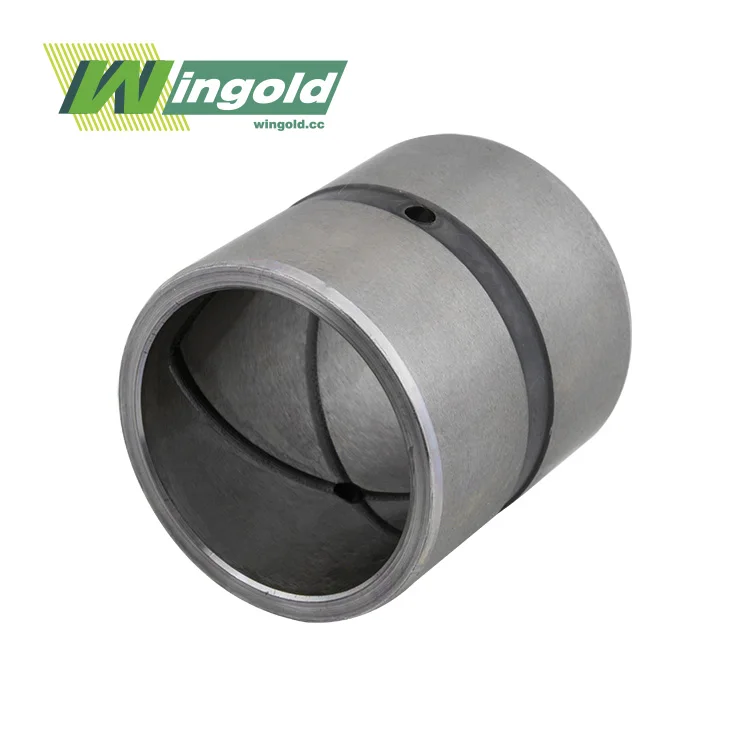

Oil pump bushings are integral components in the efficient operation of oil pumps. These precision-engineered parts serve as bearings, providing a smooth surface for rotating shafts within the pump. By maintaining proper clearance and alignment, oil pump bushings ensure optimal performance and longevity of the pump mechanism.

The primary function of oil pump bushings is to reduce friction between moving parts. This reduction in friction not only enhances the pump's efficiency but also minimizes wear on critical components. Additionally, these bushings play a vital role in maintaining proper oil pressure by preventing internal leakage within the pump.

Types of Oil Pump Bushings and Their Characteristics

Various types of oil pump bushings are available, each suited to specific applications and operating conditions. Bronze bushings are widely used due to their excellent wear resistance and compatibility with many lubricants. Babbitt-lined bushings offer superior conformability and embedability, making them ideal for high-load applications.

Some advanced bushing materials, like those offered by Wingold Bearing, incorporate self-lubricating properties. These innovative bushings, such as the WGB-1P series, provide superior wear resistance even without external lubrication. This characteristic makes them particularly suitable for applications involving frequent reciprocation and large lateral forces.

Identifying Signs of Oil Pump Bushing Wear

Audible Indicators of Bushing Wear

One of the most noticeable signs of oil pump bushing wear is unusual noise during operation. As bushings deteriorate, they may produce distinct sounds that can alert operators to potential issues:

- Squealing or whining noises, particularly during startup or under load

- Knocking or rattling sounds, indicating excessive clearance between the bushing and shaft

- Intermittent grinding noises, suggesting severe wear or potential failure

These auditory cues often precede more serious problems and should not be ignored. Regular auditory inspections can help identify bushing wear at an early stage, allowing for timely intervention.

Performance-Related Symptoms of Worn Bushings

As oil pump bushings wear, the pump's performance can be significantly affected. Some performance-related symptoms to watch for include:

- Reduced pump efficiency, resulting in decreased oil flow or pressure

- Increased power consumption to maintain the same output

- Inconsistent or fluctuating oil pressure

- Longer warm-up times for the pump to reach optimal operating conditions

These performance issues can have a cascading effect on the entire system, potentially leading to increased wear on other components and reduced overall efficiency.

Visual Inspection for Bushing Wear

Regular visual inspections can reveal signs of oil pump bushing wear before they lead to catastrophic failure. During these inspections, look for:

- Visible scoring or grooving on the bushing surface

- Discoloration or heat marks, indicating overheating due to insufficient lubrication

- Metal particles in the oil, suggesting accelerated wear

- Misalignment between the shaft and bushing

- Oil leakage around the bushing area

Advanced inspection techniques, such as borescope examinations, can provide a more detailed view of bushing conditions without disassembling the pump.

Solutions and Preventive Measures for Oil Pump Bushing Wear

Replacement Strategies for Worn Bushings

When oil pump bushings show significant wear, replacement is often the most effective solution. The replacement process should follow these key steps:

1. Carefully remove the worn bushing, ensuring no damage to the housing

2. Clean and inspect the housing for any damage or irregularities

3. Select a high-quality replacement bushing, such as those offered by Wingold Bearing, ensuring proper fit and material compatibility

4. Install the new bushing with precision, maintaining correct alignment

5. Perform a run-in procedure to ensure optimal performance of the new bushing

It's crucial to choose replacement bushings that match or exceed the original specifications. Wingold's WGB-1P series, for example, offers superior wear resistance and is especially suitable for applications with frequent reciprocation and large lateral forces.

Maintenance Practices to Extend Bushing Life

Implementing proper maintenance practices can significantly extend the life of oil pump bushings:

- Regular lubrication: Ensure proper lubrication according to manufacturer specifications

- Alignment checks: Periodically verify and adjust pump alignment to prevent uneven wear

- Filtration maintenance: Regularly clean or replace oil filters to minimize contaminants

- Operating within specifications: Avoid overloading or over-speeding the pump

- Temperature monitoring: Keep operating temperatures within recommended ranges

For pumps using self-lubricating bushings like those in Wingold's product line, maintenance requirements may be reduced, but regular inspections remain crucial.

Upgrades and Innovations in Oil Pump Bushing Technology

Advancements in bushing technology offer opportunities to improve pump performance and longevity:

- Self-lubricating materials: Bushings with embedded lubricants reduce maintenance needs

- Composite materials: Advanced composites offer improved wear resistance and reduced friction

- Surface treatments: Specialized coatings can enhance durability and performance

- Smart bushings: Integrated sensors for real-time wear monitoring

Wingold Bearing's innovative products, such as those based on the WGB-1P design, incorporate advanced materials and manufacturing techniques to provide superior performance in demanding applications.

Conclusion

Understanding the signs of oil pump bushing wear and implementing effective solutions is crucial for maintaining the efficiency and longevity of oil pumps. By staying vigilant for audible, performance-related, and visual indicators of wear, operators can address issues before they lead to costly failures. Regular maintenance, timely replacements, and adoption of advanced bushing technologies can significantly extend pump life and improve overall system performance. For those seeking high-quality oil pump bushings or expert advice on bushing solutions, Wingold Bearing offers a range of innovative products and technical support. To learn more about our offerings or to discuss your specific needs, please contact us at info@wingold.cc.

FAQ

How often should oil pump bushings be inspected?

Regular inspections should be conducted at least quarterly, with more frequent checks for high-use or critical applications.

Can worn oil pump bushings cause damage to other pump components?

Yes, worn bushings can lead to misalignment, increased vibration, and metal-to-metal contact, potentially damaging shafts, gears, and other components.

Are self-lubricating bushings suitable for all oil pump applications?

While self-lubricating bushings offer advantages in many scenarios, their suitability depends on specific operating conditions. Consult with a specialist to determine the best option for your application.