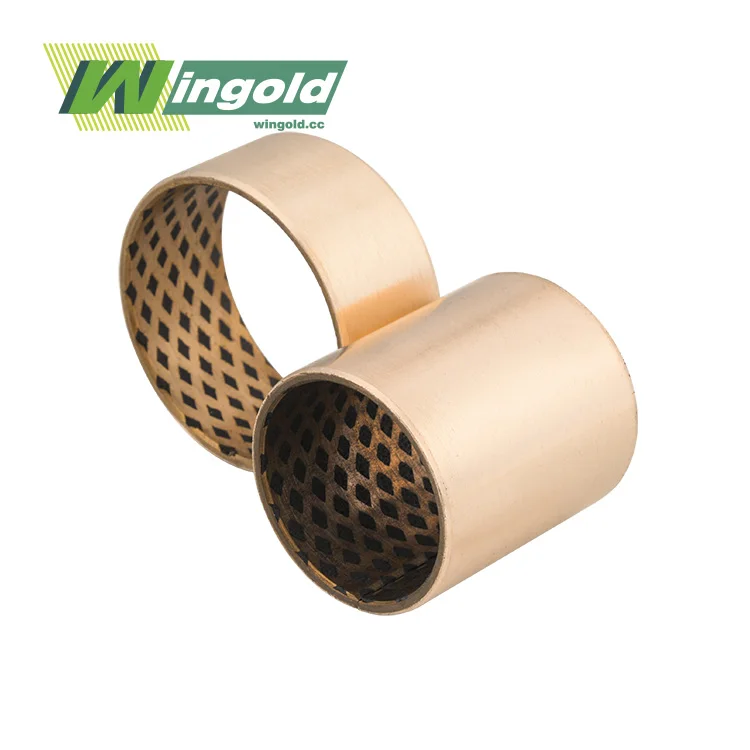

The Advantages of Small Bronze Bushings in Industrial Applications

Superior Strength and Durability

Small bronze bushings are renowned for their exceptional strength and durability, making them a preferred choice in numerous industrial applications. These compact components, crafted from high-quality bronze alloys, exhibit remarkable resistance to wear and tear, even under extreme conditions. The inherent properties of bronze, including its high tensile strength and hardness, contribute to the longevity of these bushings, ensuring they maintain their performance over extended periods.

The robustness of small bronze bushings is particularly advantageous in high-load environments. Whether utilized in heavy machinery, automotive systems, or aerospace applications, these bushings can withstand substantial pressures without deforming or failing. This resilience translates to reduced downtime and maintenance costs, as the need for frequent replacements is significantly diminished.

Excellent Thermal Conductivity

One of the standout features of small bronze bushings is their excellent thermal conductivity. This property is crucial in applications where heat dissipation is a concern. Bronze's natural ability to conduct heat efficiently helps in maintaining optimal operating temperatures, preventing overheating and potential damage to surrounding components.

In high-speed or high-friction applications, the thermal conductivity of bronze bushings plays a vital role in extending the lifespan of the entire system. By effectively dissipating heat, these bushings help reduce wear on both the bushing itself and the shaft it supports. This characteristic is particularly valuable in industries where equipment operates continuously under demanding conditions, such as in manufacturing plants or heavy machinery used in construction.

Self-Lubricating Properties

Many small bronze bushings are engineered with self-lubricating properties, a feature that significantly enhances their performance and longevity. These bushings often incorporate graphite or other lubricating materials within their structure, creating a low-friction surface that reduces wear and extends the operational life of both the bushing and the mating components.

The self-lubricating nature of these bushings is particularly advantageous in applications where regular maintenance or relubrication is challenging or impossible. This feature makes them ideal for use in hard-to-reach areas or in machinery that operates in environments where external lubrication could attract contaminants. The result is a more reliable, low-maintenance solution that contributes to overall system efficiency and reduced operational costs.

Comparing Bronze and Plastic Bushings: Performance in Various Environments

Load-Bearing Capacity

When it comes to load-bearing capacity, small bronze bushings significantly outperform their plastic counterparts. Bronze, being a metal alloy, possesses inherently higher strength and rigidity. This allows bronze bushings to withstand much higher loads without deforming or failing. In applications where heavy loads or sudden impacts are common, such as in construction equipment or industrial machinery, bronze bushings are the clear choice.

Plastic bushings, while suitable for lighter loads, have limitations when it comes to high-stress environments. They may deform under extreme pressures, leading to increased wear and potential failure. However, in applications where weight is a critical factor and loads are relatively light, plastic bushings can offer a suitable alternative.

Temperature Resistance

Temperature resistance is another area where small bronze bushings shine. Bronze has a much higher melting point compared to most plastics, allowing these bushings to operate effectively in high-temperature environments. This makes them ideal for use in applications such as furnaces, engines, or any machinery that generates significant heat during operation.

Plastic bushings, on the other hand, have a more limited temperature range. While some advanced engineering plastics can withstand moderately high temperatures, they generally cannot match the heat resistance of bronze. In extreme cold, however, certain plastics may maintain their properties better than bronze, which can become brittle at very low temperatures.

Chemical Resistance

When it comes to chemical resistance, the comparison between bronze and plastic bushings becomes more nuanced. Bronze bushings offer good resistance to many chemicals and are particularly resistant to oxidation. This makes them suitable for use in various industrial environments where exposure to certain chemicals is common.

Plastic bushings, depending on the specific type of plastic, can offer superior resistance to a wide range of chemicals. This makes them particularly useful in applications involving exposure to corrosive substances or in industries such as food processing or pharmaceuticals, where chemical inertness is crucial. However, it's important to note that not all plastics are equally resistant to all chemicals, and careful selection is necessary based on the specific environmental conditions.

Cost-Effectiveness and Long-Term Value of Small Bronze Bushings

Initial Investment vs. Longevity

When considering the cost-effectiveness of small bronze bushings, it's essential to look beyond the initial investment. While bronze bushings may have a higher upfront cost compared to plastic alternatives, their longevity often results in better long-term value. The superior durability of bronze means these bushings can outlast plastic versions several times over, especially in demanding applications.

This extended lifespan translates to fewer replacements over time, reducing not only the cost of parts but also the associated labor and downtime expenses. In industries where equipment reliability is paramount, the long-term savings and reduced interruptions to operations can far outweigh the higher initial cost of bronze bushings.

Maintenance and Replacement Costs

The maintenance requirements and replacement frequency of bushings significantly impact their overall cost-effectiveness. Small bronze bushings, particularly those with self-lubricating properties, often require minimal maintenance. Their resistance to wear and ability to operate efficiently for extended periods mean less frequent inspections and replacements are necessary.

In contrast, plastic bushings may need more frequent replacements, especially in high-stress or high-temperature environments. While the individual cost of a plastic bushing might be lower, the cumulative expense of more frequent replacements, along with the associated labor and downtime, can quickly surpass the cost of a more durable bronze alternative.

Energy Efficiency and System Performance

The impact of bushing material on overall system performance is an often-overlooked aspect of cost-effectiveness. Small bronze bushings, with their superior strength and self-lubricating properties, can contribute to improved energy efficiency in machinery. The reduced friction and better heat dissipation characteristics of bronze can lead to smoother operation and less energy waste.

This improved efficiency not only reduces operating costs but can also extend the life of other components in the system. In applications where precision and consistent performance are crucial, the stability and reliability of bronze bushings can lead to better overall system performance, potentially improving product quality and reducing waste.

Conclusion

In conclusion, while both bronze and plastic bushings have their place in various applications, small bronze bushings offer significant advantages in terms of durability, performance, and long-term cost-effectiveness, especially in demanding industrial environments. Their superior strength, excellent thermal properties, and self-lubricating capabilities make them an ideal choice for applications requiring reliability and longevity. While the initial investment may be higher, the reduced maintenance needs, longer lifespan, and improved system performance often result in substantial long-term savings.

For those seeking high-quality small bronze bushings or looking to explore customized bushing solutions, Wingold Bearing offers a wide range of options tailored to specific industry needs. With our expertise in sliding bearing solutions and commitment to quality, we can help you find the perfect bushing for your application. To learn more about our products or to discuss your specific requirements, please contact us at info@wingold.cc.

FAQs

What are the main advantages of small bronze bushings over plastic ones?

Small bronze bushings offer superior strength, better heat dissipation, and longer lifespan, making them ideal for high-load and high-temperature applications.

In what industries are small bronze bushings commonly used?

They are widely used in automotive, aerospace, heavy machinery, and manufacturing industries where reliability and durability are crucial.

Are bronze bushings more expensive than plastic bushings?

Initially, yes. However, their longevity and reduced maintenance needs often make them more cost-effective in the long run, especially in demanding applications.

Can small bronze bushings operate in high-temperature environments?

Yes, bronze bushings can withstand much higher temperatures compared to most plastic bushings, making them suitable for use in high-heat applications.

Do bronze bushings require frequent lubrication?

Many bronze bushings are self-lubricating, reducing or eliminating the need for frequent manual lubrication.