Material Properties and Performance Characteristics

Bronze Machine Bushings: The Versatile Powerhouse

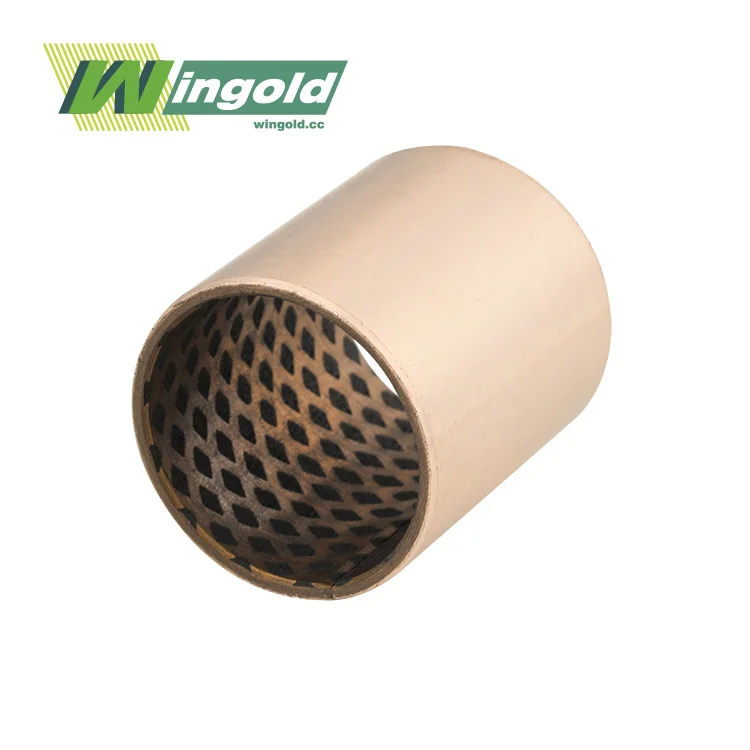

Bronze machine bushings, crafted from high-density copper alloy strips, offer a compelling combination of strength, durability, and performance. These bushings boast exceptional load-bearing capacity, often supporting up to 140 MPa, making them ideal for heavy-duty industrial applications. The inherent properties of bronze alloys, such as CuSn8, CuSn10, and CuSn12, contribute to their remarkable wear resistance and extended service life.

One of the standout features of bronze machine bushings is their excellent thermal conductivity. This characteristic allows for efficient heat dissipation, preventing overheating and ensuring stable performance even in high-temperature environments. The ability to maintain structural integrity under extreme pressure and temperature conditions makes bronze bushings a reliable choice for applications involving continuous operation or high-speed machinery.

Furthermore, bronze machine bushings exhibit natural self-lubricating properties, reducing the need for frequent lubrication and minimizing maintenance requirements. This feature is particularly advantageous in applications where regular lubrication is challenging or impractical. The surface of these bushings can be customized with diamond or hemispherical oil holes and grooves, further enhancing their lubrication capabilities and overall performance.

Nylon Bushings: Lightweight and Cost-Effective

Nylon bushings offer distinct advantages in certain applications, primarily due to their lightweight nature and cost-effectiveness. These thermoplastic components are known for their low friction coefficients, which can contribute to smooth operation and reduced wear in low-load scenarios. Nylon's inherent corrosion resistance makes it suitable for use in environments where exposure to chemicals or moisture is a concern.

However, nylon bushings have limitations when it comes to load-bearing capacity and heat resistance. They typically cannot match the high load capacities of bronze machine bushings, limiting their use in heavy-duty industrial applications. Additionally, nylon's thermal properties are less favorable compared to bronze, potentially leading to performance issues in high-temperature environments or applications involving rapid heat generation.

Steel Bushings: Strength at a Cost

Steel bushings are renowned for their exceptional strength and durability, making them suitable for high-load applications. They offer excellent wear resistance and can withstand significant mechanical stress. However, steel bushings come with their own set of drawbacks that may limit their suitability in certain scenarios.

One of the primary concerns with steel bushings is their propensity for corrosion, particularly in humid or chemically aggressive environments. This vulnerability necessitates additional protective measures, such as surface treatments or coatings, which can increase overall costs and maintenance requirements. Steel bushings also tend to have higher friction coefficients compared to bronze or nylon alternatives, potentially leading to increased wear and reduced efficiency in some applications.

Application-Specific Considerations and Industry Usage

Bronze Machine Bushings: Versatility Across Industries

The versatility of bronze machine bushings is evident in their widespread adoption across various industries. In the realm of heavy machinery, such as construction equipment and mining apparatus, bronze bushings excel due to their superior load-bearing capacity and ability to withstand harsh operating conditions. The automotive sector, particularly in chassis components and powertrain systems, benefits from the durability and self-lubricating properties of bronze bushings.

Marine applications present unique challenges due to the corrosive nature of saltwater environments. Bronze machine bushings, with their inherent corrosion resistance, prove to be an excellent choice for ship propulsion systems, rudder bearings, and other critical components exposed to marine conditions. The material's ability to maintain performance integrity in the presence of saltwater contributes to increased equipment longevity and reduced maintenance intervals.

In the aerospace industry, where precision and reliability are paramount, bronze machine bushings find applications in landing gear assemblies, flight control systems, and engine components. The material's combination of strength, wear resistance, and thermal stability aligns well with the stringent requirements of aviation applications.

Nylon Bushings: Specialized Applications

While nylon bushings may not match the overall performance of bronze in heavy-duty scenarios, they carve out a niche in specific applications. The food processing industry, for instance, benefits from nylon's FDA-compliant nature and resistance to chemicals commonly used in cleaning processes. Light-duty conveyor systems and packaging machinery often incorporate nylon bushings due to their low friction properties and cost-effectiveness.

In the automotive sector, nylon bushings find applications in non-load-bearing components such as interior trim pieces, door hinges, and pedal assemblies. The material's lightweight nature contributes to overall vehicle weight reduction efforts, aligning with fuel efficiency goals.

Steel Bushings: High-Stress Environments

Steel bushings come into their own in applications where extreme mechanical stress is the primary concern. Heavy earth-moving equipment, such as excavators and bulldozers, often utilize steel bushings in their articulation points and pivot joints. The material's high yield strength and resistance to deformation under heavy loads make it suitable for these demanding applications.

In the manufacturing sector, steel bushings are frequently employed in stamping presses and forming dies, where they must withstand repetitive high-impact forces. However, the need for regular lubrication and potential for corrosion in these environments often leads engineers to explore alternative materials or surface treatments to enhance performance and longevity.

Cost-Benefit Analysis and Long-Term Performance

Initial Investment vs. Lifecycle Costs

When evaluating the cost-effectiveness of different bushing materials, it's crucial to consider both the initial investment and long-term operational costs. Bronze machine bushings may have a higher upfront cost compared to nylon alternatives, but their superior durability and extended service life often result in lower total ownership costs over time. The reduced need for replacements and maintenance interventions can lead to significant savings in labor and downtime costs.

Steel bushings, while potentially less expensive initially, may incur higher lifecycle costs due to increased maintenance requirements, particularly in corrosive environments. The need for regular lubrication and potential replacements due to wear or corrosion can offset any initial cost savings.

Performance Longevity and Maintenance Considerations

Bronze machine bushings excel in terms of performance longevity, often outlasting both nylon and steel alternatives in comparable applications. Their self-lubricating properties and resistance to wear contribute to extended service intervals and reduced maintenance requirements. This longevity is particularly valuable in applications where equipment downtime is costly or access for maintenance is limited.

Nylon bushings, while offering low-friction operation, may require more frequent replacements in high-load or high-temperature applications. Their performance can degrade more rapidly under adverse conditions, potentially leading to increased maintenance frequency and associated costs.

Steel bushings, despite their strength, may necessitate more rigorous maintenance schedules to prevent corrosion and ensure optimal performance. The cost of corrosion prevention measures, such as specialized coatings or regular application of protective compounds, should be factored into the overall cost-benefit analysis.

Environmental Impact and Sustainability

In an era of increasing environmental awareness, the sustainability aspects of bushing materials merit consideration. Bronze machine bushings offer advantages in this regard, as they are highly recyclable and can be reprocessed without significant loss of material properties. The longevity of bronze bushings also contributes to reduced waste generation over time.

Nylon bushings, being a thermoplastic material, can also be recycled, but the process may be more complex and energy-intensive compared to metal recycling. The shorter lifespan of nylon bushings in certain applications could lead to increased material consumption over time.

Steel bushings, while recyclable, may present environmental challenges related to the energy-intensive production process and the potential for contamination from lubricants or corrosion-resistant coatings. However, advancements in steel production technology are continually improving the material's environmental footprint.

Conclusion

In the comparison of bronze machine bushings with nylon and steel alternatives, it becomes evident that each material has its unique strengths and optimal applications. Bronze machine bushings stand out for their exceptional combination of load-bearing capacity, wear resistance, thermal conductivity, and self-lubricating properties. These characteristics make them the preferred choice in a wide range of industrial applications, particularly those involving heavy loads, high temperatures, or corrosive environments.

While nylon and steel bushings have their place in specific scenarios, the versatility and long-term performance benefits of bronze often tip the scales in its favor. As engineering requirements continue to evolve, the choice of bushing material remains a critical decision that can significantly impact equipment efficiency, maintenance costs, and overall operational success.

For those seeking high-performance sliding bearing solutions, Jiashan Wingold Bearing Co., Ltd. offers a comprehensive range of bronze machine bushings tailored to meet diverse industrial needs. With over 20 years of industry experience and a commitment to innovation, Wingold provides customized solutions that optimize performance and longevity. To learn more about how our bronze machine bushings can enhance your applications, contact us at info@wingold.cc.

FAQ

What are the key advantages of bronze machine bushings over nylon and steel alternatives?

Bronze machine bushings offer superior load capacity, excellent thermal conductivity, natural self-lubricating properties, and high corrosion resistance. They typically outperform nylon in high-load and high-temperature applications, and offer better wear resistance and lower maintenance requirements compared to steel.

In which industries are bronze machine bushings commonly used?

Bronze machine bushings find wide application in industries such as heavy machinery, automotive, marine, aerospace, and manufacturing. They are particularly valued in applications requiring high load-bearing capacity, wear resistance, and performance in challenging environments.

How do the maintenance requirements of bronze bushings compare to nylon and steel?

Bronze bushings typically require less maintenance due to their self-lubricating properties and durability. Nylon bushings may need more frequent replacement in high-stress applications, while steel bushings often require regular lubrication and corrosion prevention measures.

References

1. Szeri, A. Z. (2005). Tribology: Friction, Lubrication, and Wear. Springer.

2. Hutchings, I. M., & Shipway, P. (2017). Tribology: Friction and Wear of Engineering Materials (2nd ed.). Butterworth-Heinemann.

3. Hutchings, I. M., & Shipway, P. (2017). Tribology: Friction and Wear of Engineering Materials (2nd ed.). Butterworth-Heinemann.

4. Stachowiak, G. W., & Batchelor, A. W. (2013). Engineering Tribology (4th ed.). Butterworth-Heinemann.

5. 0(5–6), 605–616.

6. Bijwe, J., & Sharma, M. (2006). "Wear resistant materials for engineering applications: Polymers and composites." Wear, 260(5–6), 605–616.