The Role of Bronze Sleeve Bushings in Renewable Energy Applications

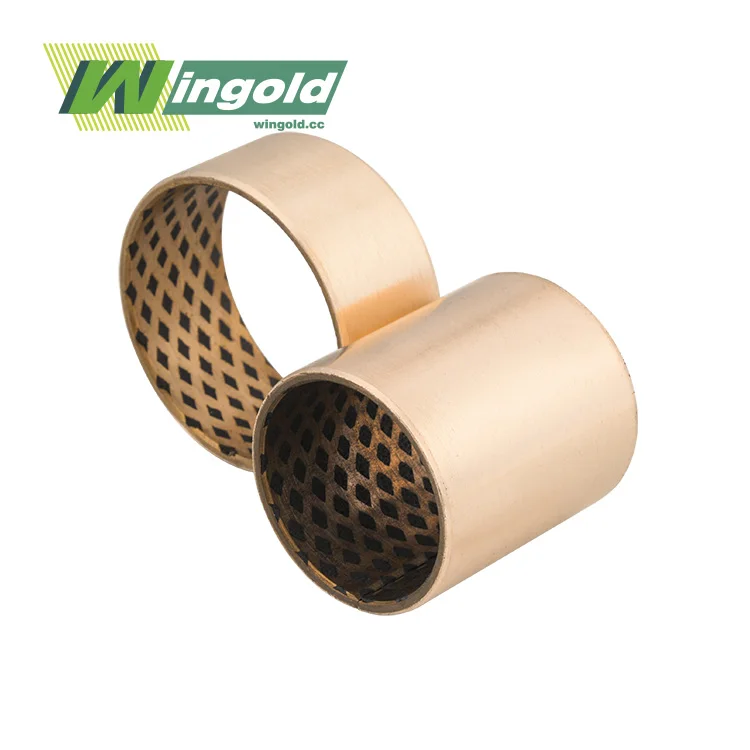

Bronze sleeve bushings have become indispensable components in the renewable energy sector, contributing significantly to the efficiency and reliability of various green energy systems. These precision-engineered parts excel in applications where traditional bearings might falter, offering unparalleled performance in challenging environments.

Wind Turbine Applications

In wind energy systems, bronze sleeve bushings play a crucial role in ensuring smooth operation and longevity. They are commonly used in pitch control systems, which adjust the angle of wind turbine blades to optimize energy capture. The self-lubricating properties of bronze bushings make them ideal for this application, as they can withstand high loads and frequent oscillatory movements without the need for constant maintenance.

Moreover, these bushings are utilized in yaw systems, which rotate the nacelle to face the wind direction. The corrosion-resistant nature of bronze alloys protects against the harsh environmental conditions often encountered in offshore wind farms, where salt spray and humidity can quickly degrade less robust materials.

Solar Energy Applications

The solar energy sector also benefits significantly from the use of bronze sleeve bushings. In solar tracking systems, these components facilitate the precise movement of solar panels to follow the sun's path, maximizing energy absorption throughout the day. The low friction coefficient of bronze bushings ensures smooth rotation with minimal wear, contributing to the overall efficiency of the system.

Additionally, bronze sleeve bushings find applications in the mounting hardware of solar panels, providing stable support while allowing for thermal expansion and contraction. This flexibility is crucial in maintaining the integrity of large-scale solar installations exposed to varying temperatures and weather conditions.

Hydroelectric Power Systems

In hydroelectric power generation, bronze sleeve bushings are essential components in turbine guide bearings and wicket gate mechanisms. These bushings must withstand substantial loads and operate reliably in submerged conditions. The inherent corrosion resistance and self-lubricating properties of bronze make it an excellent choice for these demanding applications, ensuring long-term performance with minimal maintenance requirements.

Advancements in Bronze Sleeve Bushing Technology for Renewable Energy

The renewable energy sector's rapid growth has spurred significant advancements in bronze sleeve bushing technology. Manufacturers are continuously innovating to meet the evolving demands of this dynamic industry, focusing on enhancing performance, durability, and sustainability.

Enhanced Alloy Compositions

Recent developments in metallurgy have led to the creation of specialized bronze alloys tailored for renewable energy applications. These advanced compositions offer improved wear resistance, higher load-bearing capacities, and enhanced thermal properties. For instance, some manufacturers now produce bronze self lubricating bearings, such as bronze sleeve bushings with nano-particle reinforcements, significantly increasing their strength and durability without compromising the material’s inherent self-lubricating characteristics.

Surface Engineering Techniques

Innovative surface engineering techniques are being employed to further enhance the performance of bronze sleeve bushings. Processes such as laser surface texturing create micro-patterns on the bushing surface, optimizing oil retention and reducing friction. This technology is particularly beneficial in wind turbine applications, where it can extend the lifespan of components and improve overall system efficiency.

Integration of Smart Technologies

The integration of smart technologies into bronze sleeve bushings represents a significant leap forward in predictive maintenance strategies for renewable energy equipment. Some advanced bushings now incorporate embedded sensors that can monitor temperature, vibration, and wear in real-time. This data can be transmitted to centralized monitoring systems, allowing for proactive maintenance and minimizing downtime in critical renewable energy installations.

Market Trends and Future Outlook for Bronze Sleeve Bushings in Renewable Energy

The market for bronze sleeve bushings in the renewable energy sector is poised for substantial growth in the coming years. Several key trends are shaping the industry landscape and driving innovation in bushing design and manufacturing.

Increasing Demand for Larger and More Efficient Systems

As renewable energy technologies mature, there is a growing trend towards larger, more efficient systems. This scaling up presents new challenges for component manufacturers, including those producing bronze sleeve bushings. The demand for bushings capable of handling higher loads and operating in more extreme conditions is increasing, pushing the boundaries of material science and engineering.

Focus on Sustainability and Environmental Impact

The renewable energy sector's commitment to sustainability extends to its component supply chain. Manufacturers of bronze sleeve bushings, including bronze shoulder bushings, are increasingly focusing on environmentally friendly production processes and materials. This includes developing lead-free bronze alloys and implementing recycling programs for used bushings, aligning with the broader goals of the renewable energy industry.

Customization and Rapid Prototyping

The diverse and evolving nature of renewable energy technologies necessitates a high degree of customization in component design. Bronze sleeve bushing manufacturers are adopting advanced manufacturing techniques, such as 3D printing and CNC machining, to offer rapid prototyping and customization services. This flexibility allows for quicker development cycles and more efficient integration of bushings into new renewable energy systems.

Global Market Expansion

The global push towards renewable energy is opening up new markets for bronze sleeve bushings. Emerging economies are investing heavily in green energy infrastructure, creating opportunities for bushing manufacturers to expand their global footprint. This expansion is driving competition and innovation in the industry, benefiting end-users with improved products and services.

Conclusion

The market for bronze sleeve bushings in renewable energy equipment is experiencing robust growth, driven by the sector's expansion and the critical role these components play in ensuring the efficiency and reliability of green energy systems. As the industry continues to evolve, the demand for high-performance, durable, and sustainable bushings will only increase. Manufacturers who can innovate and adapt to the changing needs of the renewable energy sector are well-positioned to capitalize on this growing market.

For those seeking high-quality bronze sleeve bushings for renewable energy applications, Wingold Bearing stands out as a leading manufacturer and supplier. With our extensive experience, commitment to innovation, and focus on customer satisfaction, we are ideally positioned to meet the diverse needs of the renewable energy sector. To learn more about our products and how we can support your renewable energy projects, please contact us at info@wingold.cc.

Frequently Asked Questions

What makes bronze sleeve bushings suitable for renewable energy applications?

Bronze sleeve bushings offer excellent durability, corrosion resistance, and self-lubricating properties, making them ideal for the demanding conditions in renewable energy equipment.

How do bronze sleeve bushings contribute to the efficiency of wind turbines?

In wind turbines, bronze sleeve bushings are used in pitch control and yaw systems, ensuring smooth operation and reducing maintenance needs, thereby enhancing overall efficiency.

Are there environmentally friendly options for bronze sleeve bushings?

Yes, manufacturers are developing lead-free bronze alloys and implementing recycling programs to make bronze sleeve bushings more environmentally friendly.

How is technology improving bronze sleeve bushings for renewable energy?

Advancements include enhanced alloy compositions, surface engineering techniques, and the integration of smart technologies for real-time monitoring.