- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

An Overview of the Benefits of Self Lubricating Bearings

In the world of industrial machinery and equipment, bearings that work well and last a long time are quite important. Bearings are the basic parts that make rotational motion possible, lower friction, and hold up structural loads. Self greasing bearings are a revolutionary new type of bearing that has many benefits over standard bearing systems that need to be lubricated on a regular basis. These innovative parts are now essential in industries that need high performance, low maintenance, and long-lasting durability.

This article goes into great detail about the benefits of self-lubricating bearings, covering their basic principles, the materials used to make them, their practical benefits, and their rising uses. By the end, you'll know exactly why more engineers and manufacturers are choosing self-lubricating bearings as the best option for modern mechanical systems.

Understanding Self Lubricating Bearings

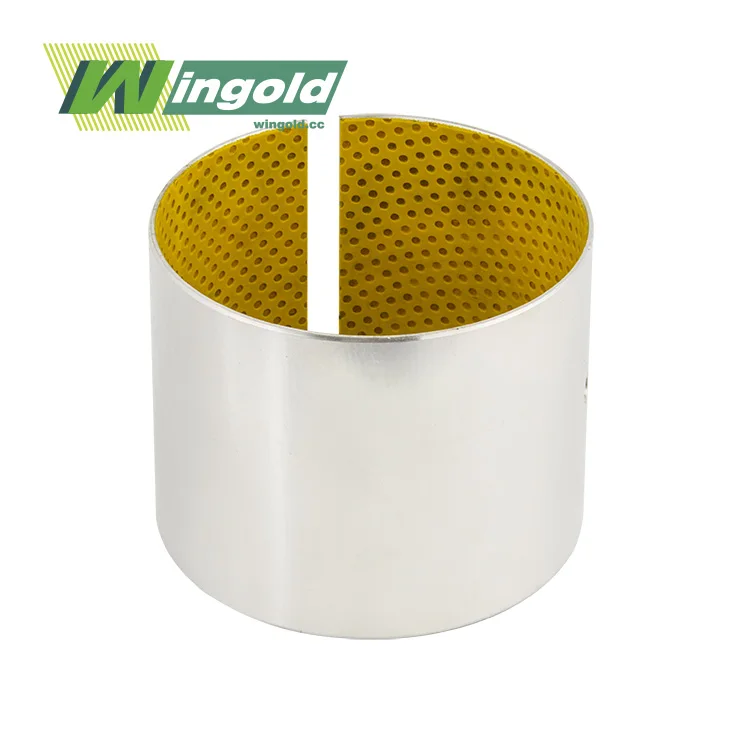

Self-lubricating bearings, commonly referred to as self greasing bearings, are cutting-edge mechanical parts made to function with little or no outside lubrication. These bearings don't need to be greased or oiled on a regular basis like traditional bearings do. Instead, they have specific materials, internal pores, or coatings that reduce friction that automatically release lubricant while they are in use.

This design not only makes things work better, but it also gets rid of frequent problems like lubricant breakdown, contamination, and uneven lubrication intervals. The need for self-lubricating bearings keeps growing as sectors work toward automation, high dependability, and low costs.

The Science Behind Self Lubrication

The self greasing bearings mechanism in these bearings usually uses porous materials that are soaked in lubricants or low-friction surface coatings. As the bearing moves or heats up while it is working, the lubricant that is inside it progressively flows to the surface, making a continuous coating of lubrication.

This mechanism operates on two key principles:

Capillary Action

The micro-pores in the bearing material serve as storage spaces. These holes let oil out as the temperature or pressure goes up. The oil is reabsorbed after the bearing cools down or stops, keeping the supply balanced.

Low-Friction Solid Lubricants

Some bearings use materials like PTFE or graphite that naturally make things slippery. These materials lower the friction between moving parts, even when there is no oil. This makes them perfect for places that are hot or have a lot of dirt.

This capacity to control its own lubrication makes it very reliable. Self-lubricating bearings allow machinery to run continuously for long periods of time while keeping everything running smoothly, making less noise, and causing less wear.

Materials Used in Self Lubricating Bearings

To achieve self-lubrication, producers of self greasing bearings use a variety of materials. The choice relies on the type of motion, the load capacity, and the conditions in the surroundings. Some common materials are:

• Sintered bronze soaked in oil, which is great for high-load, moderate-speed applications;

• Polymer composites with solid lubricants built in, which are light and resistant to corrosion;

• Metal alloys with low-friction properties, which are great for tough mechanical environments;

• PTFE or graphite coatings are great for very hot or very dry situations.

Suppliers of self greasing bearings can meet a wide range of industrial applications because each material has its own advantages. Sintered bronze, for instance, is very strong structurally, while polymer composites are silent and can handle chemicals well. Because there are so many different kinds, self-lubricating bearings can be used in almost any mechanical design problem.

Key Benefits of Self Lubricating Bearings

Self-lubricating bearings have many advantages for use in industry. Let's look at the main benefits that are making these parts more and more popular with engineers and producers.

Reduced Maintenance Requirements

One of the best things about self-lubricating bearings is that they need a lot less maintenance. Most of the time, traditional bearings need to be manually lubricated, which means that they need to be shut down on a regular basis, competent personnel, and rigorous maintenance schedules. Self greasing bearings, on the other hand, don't require any outside lubrication at all. This means:

• Lower total maintenance costs

• Less downtime for machines

• Less chance of failures caused by lubrication

• Less need for maintenance workers

• Cleaner functioning with no oil or grease leaks

This design that doesn't need maintenance is very helpful for industries where bearings are deep inside machines, such wind turbines, conveyor tunnels, or robotic systems.

Extended Service Life

Self-lubricating bearings usually last a lot longer than regular bearings. This longer life is because of:

• Continuous lubrication that keeps metal from touching metal

• Stopping premature wear that happens when lubrication isn't enough

• Lower operating temperatures because of less friction

• Not being able to get dirty, corrode, or lose its lubrication

In the long run, these improvements mean fewer system failures and cheaper costs for replacing parts. In big factories, even a minor increase in bearing life can save a lot of money on operations.

Improved Performance in Challenging Environments

Self-lubricating bearings work best in places where regular lubricants might evaporate, break down, or collect dirt. These bearings are especially useful in:

• High-temperature situations where oils break down

• Dusty and dirty places where grease would trap abrasive particles

• Equipment that needs to be submerged or underwater and needs materials that won't corrode

• Mechanisms that need to be lubricated consistently when they are under a lot of load or moving quickly

Self-lubricating bearings make guarantee that machines work reliably even under difficult situations that would break down regular lubrication systems. This is important in mining, offshore engineering, food processing, and manufacturing automation.

Applications of Self Lubricating Bearings

Self-lubricating bearings can be used in a lot of different industries and situations because they are so flexible. Let's look at some important areas where these new parts are having a big effect.

Automotive Industry

Numerous systems that need to function smoothly, quietly, and dependably in the automotive industry require self greasing bearings.

Some examples are:

• parts for the steering column

• brake and pedal systems

• door hinges and closing mechanisms

• Systems for adjusting and sliding seats

• Parts for the fuel pump and engine accessories

Self-lubricating bearings in cars help make them lighter, more fuel-efficient, quieter, and more reliable over time. All of these are very important in modern car design.

Aerospace and Aviation

Self-lubricating bearings are very reliable and light, which is a big plus for the aerospace sector.

Some uses are:

• Systems for controlling and moving flight

• devices for landing gear

• Accessories for turbine engines

• Seating and other devices in the cabin

Self-greasing bearings cut down on the time between maintenance, which makes planes safer and lowers operating expenses. They are perfect for aircraft engineering since they can handle very high and low temperatures and vibrations.

Industrial Machinery

Self-lubricating bearings are used a lot in factories for things like:

• Conveyor and packing systems

• Textile and spinning machinery

• Automation and robotic equipment

• Food and drink processing lines

• Agricultural and construction equipment

These bearings make production more efficient, lower the risk of contamination, and make sure that performance stays steady even when operations are happening at high frequencies. Because they are strong and don't get tired easily, they are a must-have in modern factories.

Conclusion

Self-lubricating bearings provide a lot of characteristics that make them a good choice for many different sectors. These new parts are changing the way machines work by making them easier to maintain, last longer, and work better in tough conditions. Self greasing bearings will become even more important as companies continue to integrate automation and look for cost-effective solutions.

As material science and engineering continue to improve, future generations of self-lubricating bearings will work even better, be more flexible, and use less energy. This will make them even more important in modern mechanical systems.

Frequently Asked Questions

Q: What are the major benefits of bearings that lubricate themselves?

A: Some of the key benefits are less maintenance, a longer service life, and better performance in tough conditions. They don't need outside lubrication, they cut down on equipment downtime, and they work reliably in places where regular bearing systems can fail.

Q: Are self-lubricating bearings good for use in high-temperature situations?

A: Yes. Many are designed to work well in hot places, however the exact restrictions depend on the materials used. To get the right bearing for your temperature needs, it's best to talk to a trustworthy self greasing bearings supplier.

Q: How long do bearings that lubricate themselves last?

A: The lifespan depends on how the bearing is used, how much weight it carries, and how it is designed. But self-lubricating bearings usually last a lot longer than regular bearings because they keep themselves lubricated and are less likely to wear out.

Experience the Power of Self Greasing Bearings with Wingold

For a variety of sectors, Wingold Bearing is a leader in the supply of high-quality self greasing bearings. Our new products, such the WGB-1 oil-free lubricated bearing, work better, last longer, and cost less than other products. We make unique bearing solutions that match your exact needs thanks to our superior production capabilities and experienced engineering support.

Upgrade your machines with Wingold's renowned technology and enjoy all the benefits of self-lubricating bearings. Send us an email at info@wingold.cc to find out more about our products and how we can help you with your bearing needs.

References

1. Smith, J. (2022). "Advancements in Self-Lubricating Bearing Technology." Journal of Tribology and Lubrication Engineering, 45(3), 78-92.

2. Johnson, A. & Brown, L. (2021). "Performance Analysis of Self-Lubricating Bearings in Extreme Environments." International Journal of Mechanical Engineering, 33(2), 201-215.

3. Thompson, R. (2023). "Applications of Self-Lubricating Bearings in Modern Industry." Industrial Machinery Review, 18(4), 56-70.

4. Davis, M. et al. (2020). "Comparative Study of Self-Lubricating Materials for Bearing Applications." Materials Science and Technology, 28(1), 112-126.

5. Lee, S. & Wilson, P. (2022). "Lifecycle Cost Analysis of Self-Lubricating Bearings vs. Traditional Bearings." Journal of Engineering Economics, 40(3), 301-315.

Learn about our latest products and discounts through SMS or email