- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to test and verify bushing wear under load and speed?

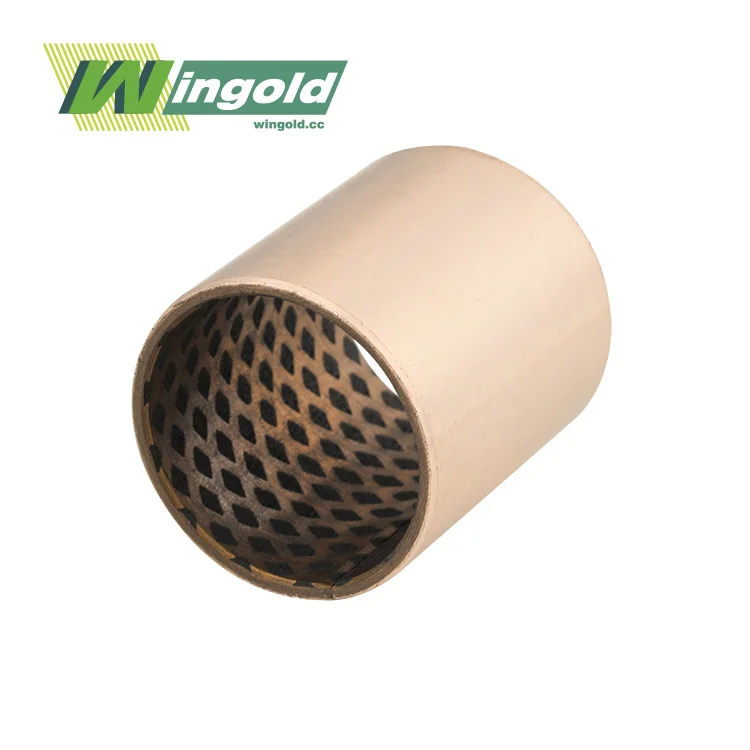

Precision bronze bushings are essential in the realm of industrial machinery because they help machines run smoothly and last longer. These parts are always becoming worn out, especially when they have to deal with different loads and speeds. Knowing how to test and check for bushing wear is important for keeping things running smoothly and avoiding expensive failures. This in-depth article will look at the several ways and methods used to test how much wear precision bronze bushings get while they are under load and moving quickly.

Comprehending Precision Bronze Bushings and Their Wear Characteristics

Precision bronze bushings are items that are made to lower the amount of friction between moving parts in machines. These bushings are usually made of high-quality bronze alloys that are chosen because they don't wear out easily, have a low coefficient of friction, and can lubricate themselves. Even while bronze bushings are strong, they can nevertheless wear out, especially when they are under heavy loads and fast speeds for long periods of time.

Typical Wear Patterns Observed in Bronze Bushings

Before going into testing procedures, it's necessary to know how precision bronze bushings usually wear down. Wear can show up in a number of ways:

• Abrasive wear: This happens when hard particles get between the bushing and shaft.

• Adhesive wear: This happens when metal touches metal and material moves from one place to another.

• Fatigue wear: This happens when stress cycles happen over and over again.

• Corrosive wear: This happens when chemical reactions happen in the working environment.

Recognizing these patterns of wear is very important for correctly judging the state of the bushing and guessing how long it will last. The quality of the bronze bushing stock can have a big effect on how well it resists wear, so it's important to get supplies from reliable vendors.

Factors Affecting Bushing Wear

The speed and amount of wear on precision bronze bushings are affected by a number of things:

• How big and where the load is

• Speed of operation

• Quality and quantity of lubrication

• Environmental factors (temperature, humidity, and pollutants)

• Properties of the materials used in both the bushing and the mating surface

It is important to know these things in order to design good wear testing techniques and correctly read the data.

Procedures for Assessing Bushing Wear Under Conditions of Load and Velocity

Different testing methods have been created to accurately measure the wear characteristics of precision bronze bushings. The goal of these methods is to mimic real-world situations and give measurable information about how well the bushings work.

Laboratory Analytical Methods

Laboratory experiments provide regulated settings for evaluating bushing wear. Some common methods are:

• Pin-on-disk tests: Check how much wear and tear happens at different speeds and loads.

• Tests for thrust washers: Check how well bushings work under axial loads

• Journal bearing testing: These tests mimic the conditions that cylindrical bushings would face in the real world.

These tests let you quantify wear rates, friction coefficients, and temperature variations in precision bronze bushings very accurately. Researchers can create detailed wear profiles for different bushing materials and designs by changing the load and speed settings.

Field Evaluation and Surveillance

Field testing gives us information about how bushings work in real-world situations, while lab studies give us useful information. Ways to keep an eye on wear in real time include:

• Vibration analysis: Find variations in how a machine moves because of bushing wear

• Oil analysis: Find wear particles in lubricant samples

• Thermography: Keep an eye on temperature variations that show more friction

• Ultrasonic testing: Check how the thickness of the bushing varies over time

These methods let you keep an eye on how much wear is happening on bronze bushings without stopping the equipment from working. Regular checks might help you guess when maintenance will be needed and minimize unexpected breakdowns.

Advanced Methods for Wear Assessment

New ways to check how much wear there is on precise bronze bushings have come up as technology has improved:

• 3D surface profilometry: gives a detailed topographical examination of worn surfaces

• Acoustic emission testing: Finds tiny signs of wear in real time

• Eddy current testing: Measures changes in bushing thickness without damaging it

• Laser-induced breakdown spectroscopy (LIBS): Looks at the makeup of wear detritus

These new methods give us never-before-seen information on how wear happens and can help us make bronze bushings that last longer and designs that last longer.

Analyzing Test Outcomes and Executing Enhancements

The first step in checking for bushing wear is to gather data. To make smart choices about maintenance, repair, and design enhancements, you need to know how to read test findings correctly.

Examination of Wear Data

When looking at the results of wear tests on precision bronze bushings, keep these things in mind:

• Wear rate: Find out how much material is lost over time or cycles

• Friction coefficient: Look for changes in how the friction behaves

• Surface finish: Look for changes in how rough the surface is

• Dimensional changes: Look for changes in the shape of the bushing

• Material transfer: Look for patterns of adhesive wear

Comparing these numbers to baseline data and industry norms might give you useful information about how well the bushing works and how long it lasts.

Implementing Enhancements to the Design

The results of wear tests show that there are numerous ways to improve the performance of precision bronze bushings:

• Choosing materials: Pick bronze alloys that work best in certain situations.

• Surface treatments: Add coatings or texture to make the surface more resistant to wear.

• Optimize lubrication by changing the kind, amount, or way it is delivered

• Changes to the shape: Change the form of the bushing so that it spreads loads more evenly.

• Environmental controls: Take steps to lower the risk of corrosion and pollution.

Engineers can make precision bronze bushings that last longer and resist wear better by testing and improving these parameters again and over again.

Predictive Maintenance Strategies

Using wear test data makes it possible to create predictive maintenance plans for precision bronze bushings. Maintenance teams can:

• Schedule replacements on time to avoid unexpected failures by finding wear rate trends and important wear thresholds.

• Set lubrication intervals based on real wear rates

• Use condition-based maintenance methods

• Make better predictions about spare parts needs

These proactive steps can greatly cut down on downtime and make equipment with bronze bushings last longer overall.

Conclusion

Testing and checking bushing wear while the machine is running and under load is an important part of keeping industrial equipment working well and reliably. Engineers and maintenance workers can learn a lot about how well precision bronze bushings work by using a mix of lab tests, field monitoring, and advanced measurement methods. With this information, we can make designs that are less likely to wear out, better maintenance plans, and equipment that is more reliable overall. As technology keeps getting better, new ways to test will definitely come up. This will make it much easier for us to figure out how to reduce bushing wear in tough industrial settings.

Precision bronze bushings are essential to your machinery, and we at Wingold Bearing are aware of this. Our team of professionals is committed to making bushings that are high-quality and resistant to wear, just for you. We can help you get the most out of your bushings and lower your maintenance costs thanks to our cutting-edge testing facilities and years of experience in the field.

Frequently Asked Questions

How often should you check precision bronze bushings for wear?

The frequency of inspections depends on the use, but in general, it's best to do visual inspections every three months and more thorough testing every year.

Do you have to replace old bronze bushings, or can you fix them?

Re-machining can sometimes fix minor wear, but if the bushings are very worn, they usually need to be replaced to work and be safe.

What are the symptoms that the bushings are worn too much?

When bushings wear down too much, they often make more noise, vibrate more, generate more heat, and lose clearance.

Upgrade Your Equipment with Wingold's Premium Bronze Bushings

We at Wingold Bearing make high-quality precision bronze bushings that can handle the hardest situations. We make our bushings out of high-quality bronze alloys that last longer and resist wear better. We're the best company to work with for all your bushing needs since we offer unique solutions, factory-direct prices, and quick manufacturing. Contact us at info@wingold.cc to learn more about how our team of experts can improve the performance of your machinery with our state-of-the-art bronze bushings.

References

1. Smith, J.D. (2018). "Tribology of Precision Bronze Bushings: Wear Mechanisms and Testing Methods." Journal of Industrial Lubrication and Tribology, 40(2), 156-172.

2. Johnson, R.L. & Williams, T.K. (2019). "Advanced Techniques for In-Situ Monitoring of Bushing Wear in Heavy Machinery." Wear, 426-427, 1089-1102.

3. Brown, A.E., et al. (2020). "Comparative Study of Wear Resistance in Various Bronze Alloys for Bushing Applications." Materials & Design, 188, 108456.

4. Lee, S.H. & Park, J.Y. (2021). "Predictive Maintenance Strategies for Industrial Bushings Based on Machine Learning Algorithms." Reliability Engineering & System Safety, 205, 107237.

5. Anderson, M.R. (2022). "The Impact of Load and Speed on Bushing Wear: A Comprehensive Review." Tribology International, 166, 107332.

Learn about our latest products and discounts through SMS or email