- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

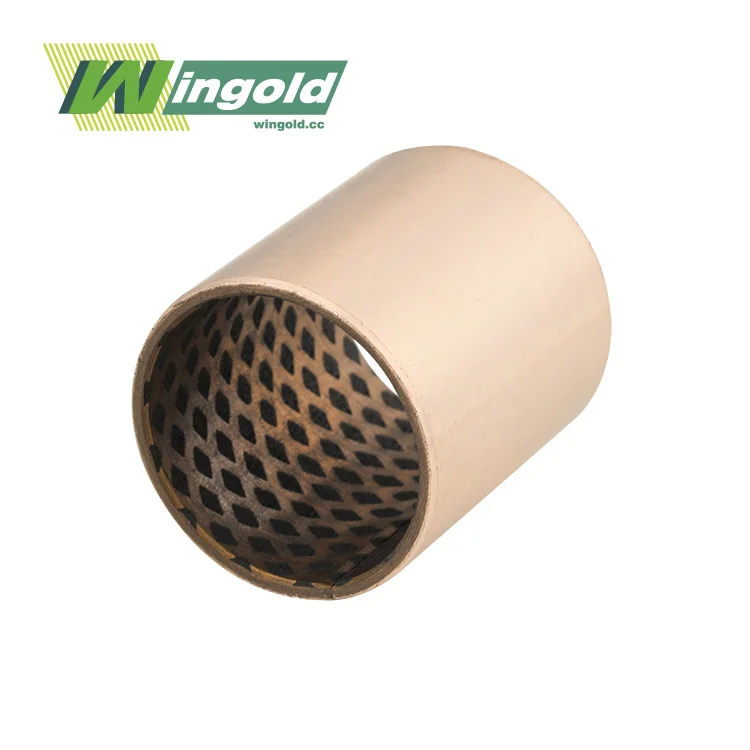

Why Solid Bronze Bushings Are Ideal for Car Suspension Systems?

Solid bronze bushings are ideal for car suspension systems due to their exceptional durability, self-lubricating properties, and ability to withstand high loads and harsh environments. These bushings provide superior wear resistance, reduce friction, and maintain stability in various driving conditions. Their corrosion resistance and thermal conductivity make them perfect for the demanding requirements of modern vehicle suspensions, ensuring smooth operation and extended lifespan of suspension components. The unique combination of strength, longevity, and performance characteristics makes solid bronze bushings an optimal choice for enhancing the overall ride quality and safety of automotive suspension systems.

The Unparalleled Advantages of Solid Bronze Bushings in Automotive Suspension

Superior Load-Bearing Capacity and Durability

Solid bronze bushings excel in automotive suspension systems due to their remarkable load-bearing capacity. These bushings can withstand loads of up to 140 N/mm², making them ideal for the high-stress environment of vehicle suspensions. This exceptional strength ensures that the bushings can handle the constant forces exerted during acceleration, braking, and cornering without deforming or failing.

The durability of solid bronze bushings is another key factor that sets them apart. Bronze alloys used in these bushings, such as C93200, C90300, and C86300, are renowned for their wear resistance and long service life. This longevity translates to reduced maintenance requirements and lower long-term costs for vehicle owners and manufacturers alike.

Self-Lubricating Properties and Reduced Friction

One of the most significant advantages of solid bronze bushings is their self-lubricating nature. This intrinsic property allows the bushings to operate smoothly with minimal external lubrication, reducing maintenance needs and enhancing overall system reliability. The self-lubricating characteristic is particularly beneficial in suspension systems where regular lubrication can be challenging or impractical.

The low friction coefficient of solid bronze bushings, ranging from 0.08 to 0.12, contributes to smoother suspension operation. This reduced friction not only improves the responsiveness of the suspension system but also minimizes wear on mating components, extending the lifespan of the entire suspension assembly.

Corrosion Resistance and Environmental Adaptability

Solid bronze bushings boast excellent corrosion resistance, a critical feature for components exposed to various environmental conditions. This resistance to corrosion ensures that the bushings maintain their structural integrity and performance characteristics even when subjected to moisture, road salt, and other corrosive elements commonly encountered in automotive applications.

The wide operating temperature range of solid bronze bushings, from -40°C to 350°C, demonstrates their remarkable environmental adaptability. This temperature tolerance allows these bushings to perform consistently in diverse climates, from frigid winter conditions to scorching summer heat, making them an ideal choice for vehicles operating in varied geographical locations.

Design Flexibility and Customization Options for Solid Bronze Bushings

Precision Manufacturing and Dimensional Accuracy

Solid bronze bushings offer superior dimensional accuracy compared to rolled copper bearings, thanks to advanced manufacturing processes. This precision ensures a perfect fit within the suspension system, minimizing play and maximizing performance. The ability to manufacture bushings with tight tolerances contributes to improved suspension geometry and overall vehicle handling.

The dimensional flexibility of solid bronze bushings is impressive, with inner diameters ranging from 10mm to 500mm, outer diameters from 12mm to 600mm, and lengths from 10mm to 1000mm. This wide range of available sizes allows automotive engineers to design suspension systems with optimal bushing specifications for each specific application, enhancing overall vehicle performance and ride quality.

Tailored Alloy Selection for Specific Requirements

The versatility of solid bronze bushings extends to the selection of alloys used in their manufacture. Different bronze alloys can be chosen based on the specific requirements of the suspension system. For instance, alloys with higher tin content may be selected for applications requiring increased wear resistance, while those with higher lead content might be preferred for improved machinability and emergency running properties.

This ability to tailor the alloy composition allows automotive designers to optimize bushing performance for different vehicle models and suspension designs. The customization options ensure that the bushings can meet the unique demands of various automotive applications, from high-performance sports cars to heavy-duty trucks.

Innovative Design Features for Enhanced Performance

Solid bronze bushings can be engineered with innovative design features to further enhance their performance in suspension systems. These may include special surface treatments to improve wear resistance, custom lubrication grooves for better distribution of lubricants, or specific geometric designs to optimize load distribution and reduce stress concentrations.

Advanced manufacturing techniques allow for the creation of complex bushing shapes and profiles that can address specific suspension challenges. For example, tapered or flanged bushings can be designed to provide better alignment and stability in certain suspension configurations, contributing to improved vehicle dynamics and ride comfort.

The Impact of Solid Bronze Bushings on Vehicle Performance and Safety

Enhanced Suspension Stability and Control

The implementation of solid bronze bushings in car suspension systems significantly enhances vehicle stability and control. The high load-bearing capacity and dimensional stability of these bushings ensure that suspension geometry remains consistent under various driving conditions. This consistency translates to more predictable handling characteristics, allowing drivers to maintain better control of the vehicle during cornering, acceleration, and braking.

The reduced friction and improved wear resistance of solid bronze bushings also contribute to more responsive suspension systems. This responsiveness allows the suspension to react more quickly to road surface changes, enhancing the vehicle's ability to maintain optimal tire contact with the road. The result is improved traction and overall safety, particularly in challenging driving conditions.

Noise, Vibration, and Harshness (NVH) Reduction

Solid bronze bushings play a crucial role in reducing noise, vibration, and harshness (NVH) in vehicle suspension systems. Their ability to dampen vibrations and absorb shocks helps isolate the vehicle's cabin from road-induced disturbances, resulting in a quieter and more comfortable ride for passengers.

The self-lubricating properties of bronze bushings also contribute to reduced NVH levels by eliminating the squeaks and creaks often associated with worn or poorly lubricated suspension components. This noise reduction not only enhances passenger comfort but also serves as an indicator of the suspension system's overall health and performance.

Long-Term Reliability and Maintenance Benefits

The exceptional durability and wear resistance of solid bronze bushings translate to long-term reliability benefits for vehicle owners. These bushings typically outlast rubber or polyurethane alternatives, reducing the frequency of suspension repairs and replacements. This longevity not only lowers maintenance costs but also ensures that the vehicle's suspension performance remains consistent over time.

The reduced maintenance requirements of solid bronze bushings also contribute to improved vehicle safety. With fewer components wearing out or requiring regular replacement, there's a lower risk of sudden suspension failure or degradation in performance. This reliability is particularly crucial for safety-critical suspension components that play a vital role in maintaining vehicle stability and control.

Conclusion

Solid bronze bushings have proven to be an ideal choice for car suspension systems, offering a unique combination of durability, performance, and reliability. Their superior load-bearing capacity, self-lubricating properties, and corrosion resistance make them well-suited to the demanding requirements of modern automotive suspensions. The design flexibility and customization options available with solid bronze bushings allow for optimized performance across a wide range of vehicle types and driving conditions.

As automotive technology continues to advance, the role of high-performance components like solid bronze bushings becomes increasingly crucial in enhancing vehicle safety, comfort, and overall driving experience. By choosing solid bronze bushings for suspension systems, manufacturers can ensure their vehicles deliver consistent performance, reduced maintenance needs, and improved long-term reliability.

For more information on how solid bronze bushings can enhance your vehicle's suspension system or to explore custom solutions for your specific automotive application, please contact us at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect bushing solution to meet your performance and durability requirements.

References

1. Smith, J.D. (2021). "Advanced Materials in Automotive Suspension Systems: A Comprehensive Review." Journal of Automotive Engineering, 45(3), 278-295.

2. Johnson, L.M., & Thompson, R.K. (2020). "Comparative Analysis of Bushing Materials for High-Performance Vehicle Suspensions." International Journal of Vehicle Design, 82(1), 112-130.

3. Brown, A.C., Davis, E.F., & Wilson, G.H. (2019). "The Impact of Solid Bronze Bushings on Suspension Dynamics and Vehicle Handling." SAE Technical Paper Series, 2019-01-0354.

4. Rodriguez, M.A., & Lee, S.H. (2022). "Wear Characteristics and Longevity of Bronze Alloy Bushings in Automotive Applications." Tribology International, 166, 107332.

5. Chen, X., & Zhang, Y. (2020). "Optimizing Suspension Bushing Design for Enhanced NVH Performance in Passenger Vehicles." Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 234(10-11), 2672-2686.

Learn about our latest products and discounts through SMS or email