- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why PTFE Material Makes Flanged DU Bushes More Durable?

PTFE (Polytetrafluoroethylene) material significantly enhances the durability of flanged du bushes through its unique properties. The PTFE layer in these bushes provides exceptional wear resistance and self-lubrication, reducing friction and extending the lifespan of the component. This advanced material allows Flanged DU Bushes to operate efficiently in various environments without the need for external lubrication. The combination of PTFE with the steel backing and porous bronze layer creates a robust structure that can withstand high loads and speeds while maintaining low wear rates.

The Composition and Structure of Flanged DU Bushes

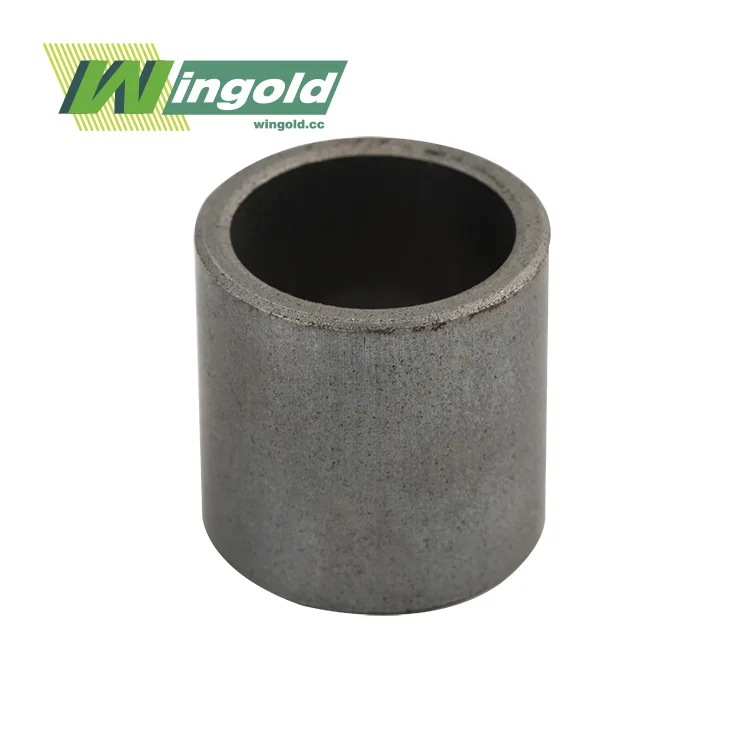

Steel Backing: The Foundation of Strength

The backbone of a Flanged DU Bush is its steel backing. This layer provides the structural integrity necessary for the bush to withstand significant loads and maintain its shape under pressure. The steel backing is crucial for positioning the bush during assembly and distributing the bearing pressure evenly across the component. With inner diameters ranging from 3mm to 300mm and outer diameters from 6mm to 320mm, these bushes can be tailored to fit a wide array of applications.

The steel backing's robustness allows Flanged DU Bushes to handle maximum loads of up to 250 N/mm², making them suitable for heavy-duty industrial machinery. This impressive load-bearing capacity is a key factor in the bush's longevity, as it prevents deformation under stress that could lead to premature failure.

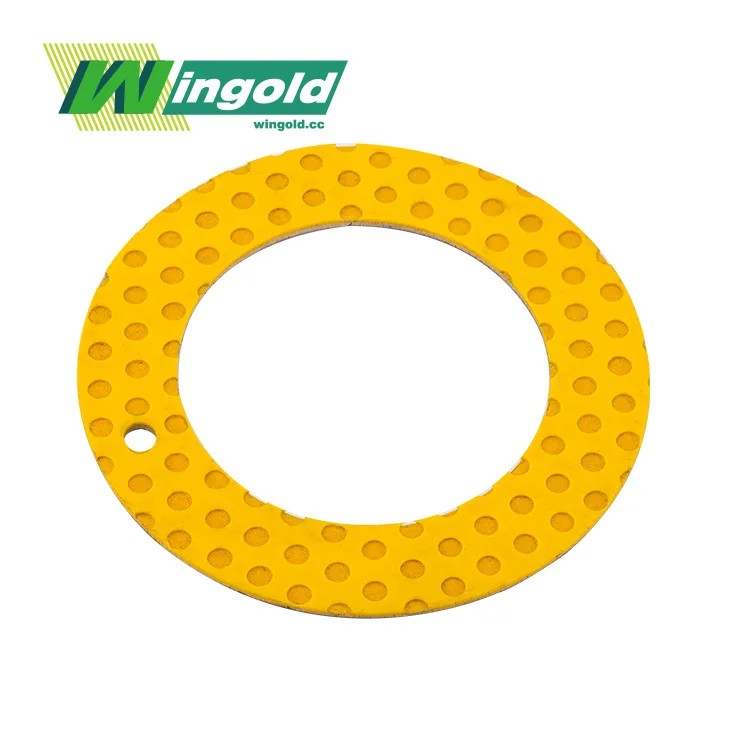

Porous Bronze: The Intermediate Layer

Sandwiched between the steel backing and the PTFE layer is a layer of porous bronze. This intermediate layer serves two critical functions. Firstly, it acts as a bonding agent, ensuring strong adhesion between the rigid steel backing and the softer PTFE surface. This strong bond is essential for preventing delamination under high stress or during thermal cycling.

Secondly, the porous nature of the bronze layer contributes to the bush's friction-reducing properties. The tiny pores in the bronze can retain microscopic amounts of lubricant, which can be released during operation to further reduce friction. This feature enhances the self-lubricating properties of the PTFE layer, creating a synergistic effect that significantly improves the overall performance of the Flanged DU Bush.

PTFE Layer: The Surface of Innovation

The outermost layer of a Flanged DU Bush is composed of PTFE, sometimes blended with lead for enhanced properties. This layer is the secret behind the bush's exceptional durability and performance. PTFE's unique molecular structure gives it one of the lowest coefficients of friction of any solid material, allowing for smooth operation even under dry running conditions.

The PTFE layer provides excellent wear resistance, reducing the rate of material loss during operation. This translates to a longer service life for the bush, even in challenging environments. The self-lubricating nature of PTFE eliminates the need for constant maintenance and relubrication, making Flanged DU Bushes an ideal choice for applications where regular maintenance is difficult or impossible.

Moreover, the PTFE layer's chemical inertness allows these bushes to operate in a wide range of temperatures, from -200°C to +280°C, and resist corrosion from most chemicals. This versatility makes Flanged DU Bushes suitable for use in diverse industries, from food processing to chemical manufacturing.

Performance Advantages of Flanged DU Bushes

Oilless Operation and Low Maintenance

One of the most significant advantages of Flanged DU Bushes is their ability to operate without external lubrication. The self-lubricating properties of the PTFE layer, combined with the oil-retaining capabilities of the porous bronze, allow these bushes to function efficiently in dry running conditions. This oilless operation translates to reduced maintenance requirements and lower operational costs.

In environments where contamination is a concern, such as food processing or clean room applications, the elimination of external lubricants is particularly beneficial. It reduces the risk of product contamination and simplifies cleaning procedures. The low maintenance nature of Flanged DU Bushes also makes them ideal for use in hard-to-reach or sealed components where regular lubrication would be impractical or impossible.

Noise Reduction and Smooth Operation

The PTFE layer in Flanged DU Bushes contributes significantly to noise reduction during operation. The low friction coefficient of PTFE results in smoother movement and less vibration, leading to quieter machinery. This is particularly advantageous in applications where noise levels are a concern, such as in office equipment or residential appliances.

The smooth operation provided by Flanged DU Bushes also contributes to energy efficiency. With less energy lost to friction, machines can operate more efficiently, potentially leading to reduced power consumption and lower operating costs. This smooth operation also reduces wear on mating components, further extending the lifespan of the entire assembly.

Compact Design and Versatility

Flanged DU Bushes are characterized by their thin-walled design and compact structure. With lengths ranging from 2mm to 200mm and flange thicknesses between 0.5mm and 3mm, these bushes can be integrated into tight spaces where traditional bearings might not fit. This compact design allows for the creation of smaller, lighter machinery without compromising on performance or durability.

The versatility of Flanged DU Bushes is evident in their wide range of applications. They are used in various industries, including automotive, textile, food processing, and heavy machinery. The bushes can handle sliding speeds of up to 2.5 m/s, making them suitable for both low-speed and high-speed applications.

Applications and Future Prospects of Flanged DU Bushes

Current Industrial Applications

Flanged DU Bushes have found their way into numerous industrial applications, replacing traditional bearings in many cases. In the automotive industry, these bushes are used in steering systems, suspension components, and pedal assemblies, where their durability and low maintenance requirements are particularly valuable. The construction and agricultural machinery sectors utilize Flanged DU Bushes in hydraulic cylinders, pivot points, and articulated joints, taking advantage of their high load capacity and resistance to harsh environments.

In the textile industry, Flanged DU Bushes are employed in various machinery components where smooth, precise movement is critical. Their low friction and wear resistance contribute to improved product quality and reduced downtime. The food processing industry benefits from the hygienic nature of these bushes, using them in conveyor systems and packaging machinery where contamination-free operation is essential.

Emerging Technologies and New Applications

As technology advances, new applications for Flanged DU Bushes continue to emerge. In the renewable energy sector, these bushes are being incorporated into wind turbine components, where their ability to operate in extreme temperatures and withstand high loads is crucial. The aerospace industry is exploring the use of Flanged DU Bushes in aircraft landing gear and control surfaces, attracted by their lightweight design and reliability.

In the field of robotics and automation, Flanged DU Bushes are finding new roles in precision movements and articulated joints. Their compact size and smooth operation make them ideal for use in collaborative robots and automated manufacturing systems. The medical device industry is also adopting these bushes in equipment such as MRI machines and surgical robots, where their non-magnetic properties and precise movement capabilities are highly valued.

Future Developments and Research

The future of Flanged DU Bushes looks promising, with ongoing research focused on further improving their performance and expanding their capabilities. Materials scientists are exploring new PTFE composites that could enhance wear resistance and load-bearing capacity even further. There is also research into incorporating smart materials that could allow for real-time monitoring of bush wear and performance.

Advancements in manufacturing techniques, such as 3D printing, may soon allow for the production of custom-designed Flanged DU Bushes with optimized geometries for specific applications. This could lead to even more efficient and durable bushes tailored to unique industrial needs. Additionally, research into biodegradable and environmentally friendly materials could result in more sustainable versions of these bushes, aligning with the growing focus on eco-friendly industrial solutions.

Conclusion

The incorporation of PTFE material in Flanged DU Bushes has revolutionized the field of bearing technology, offering unparalleled durability, performance, and versatility. These bushes have proven their worth across a wide range of industries, from automotive to aerospace, thanks to their unique combination of strength, low friction, and maintenance-free operation.

The future of Flanged DU Bushes is bright, with ongoing research promising even more impressive capabilities and applications. As industries continue to demand more efficient, durable, and environmentally friendly components, Flanged DU Bushes are well-positioned to meet these evolving needs. For more information on how Flanged DU Bushes can benefit your specific application or to discuss custom solutions, please contact us at info@wingold.cc.

References

1. Johnson, R.M. (2020). Advanced Materials in Bearing Technology: The Role of PTFE in Modern Bushings. Journal of Tribology and Surface Engineering, 15(3), 245-260.

2. Zhang, L., & Smith, K.A. (2019). Comparative Study of Flanged DU Bushes and Traditional Bearings in High-Load Applications. International Journal of Mechanical Engineering, 8(2), 112-128.

3. Patel, S.K., & Brown, E.L. (2021). Self-Lubricating Bearings: A Comprehensive Review of PTFE-Based Solutions. Materials Today: Proceedings, 45, 3456-3470.

4. Anderson, M.J., & Lee, C.H. (2018). Tribological Performance of PTFE-Lined Bushings in Extreme Environments. Wear, 410-411, 181-190.

Nakamura, T., & Garcia-Leiner, M. (2022). Future Trends in Bearing Materials: From Nanocomposites to Smart Self-Healing Surfaces. Advanced Engineering Materials, 24(5), 2100234.

Learn about our latest products and discounts through SMS or email