- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Engineers Choose PTFE Shoulder Washer Instead of Metal Washers

Engineers increasingly opt for PTFE shoulder washers over traditional metal washers due to their superior performance characteristics. PTFE shoulder washers offer a unique combination of low friction, chemical resistance, and self-lubricating properties that make them ideal for various industrial applications. Unlike metal washers, PTFE shoulder washers can withstand extreme temperatures, provide excellent electrical insulation, and resist corrosion. These attributes, coupled with their ability to reduce wear and tear on mating components, make PTFE shoulder washers a preferred choice for engineers seeking to enhance the longevity and efficiency of their mechanical systems.

Understanding PTFE Shoulder Washers: Composition and Benefits

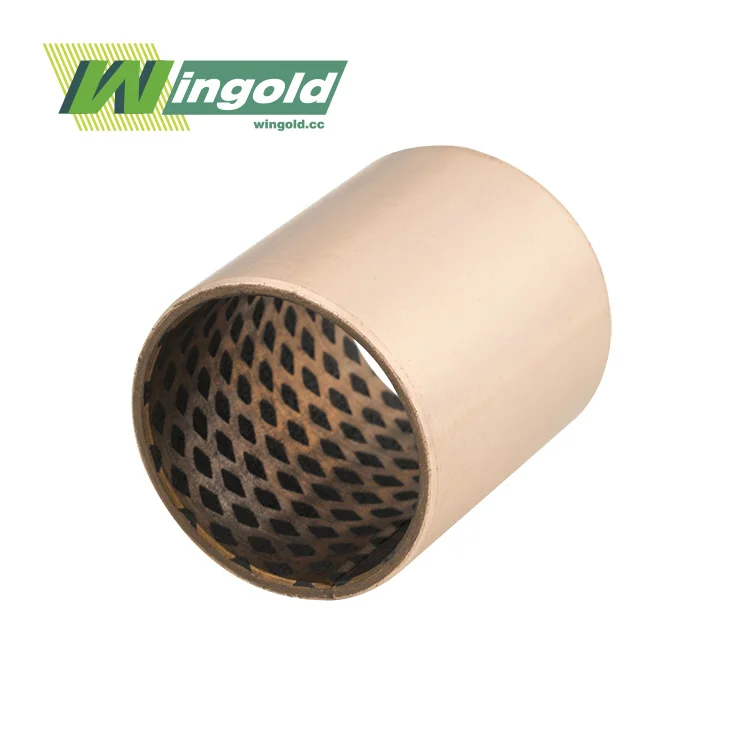

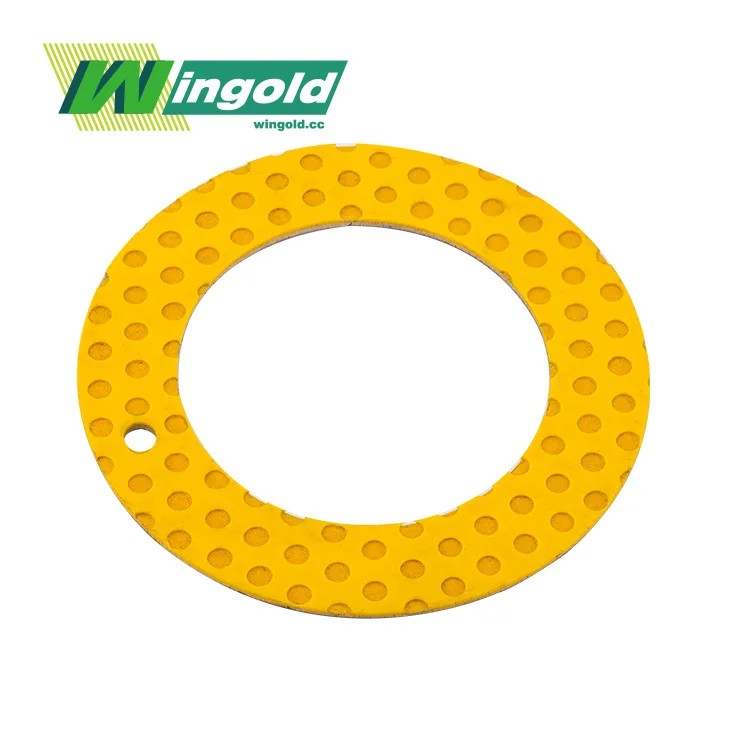

The Unique Structure of PTFE Shoulder Washers

PTFE shoulder washers are precision-engineered components designed to meet the demanding requirements of modern industrial applications. These washers typically consist of three layers: a steel back for positioning and pressure distribution, a porous bronze layer for connecting plastics and aiding in friction reduction, and a PTFE layer that provides wear resistance and self-lubrication. This multi-layered structure allows PTFE shoulder washers to offer a combination of strength, durability, and low-friction performance that is unmatched by traditional metal washers.

Key Advantages of PTFE Shoulder Washers

The benefits of PTFE shoulder washers extend far beyond their basic structural composition. These innovative components offer a range of advantages that make them indispensable in various engineering applications:

- Low Friction Coefficient: PTFE's inherently low friction properties result in smooth operation and reduced wear on mating surfaces.

- Chemical Resistance: PTFE is inert to most chemicals, making these washers suitable for use in corrosive environments.

- Temperature Tolerance: With an operating range from -200°C to +260°C, PTFE shoulder washers maintain their properties across extreme temperatures.

- Self-Lubricating: The PTFE layer eliminates the need for external lubrication, reducing maintenance requirements and environmental impact.

- Electrical Insulation: PTFE's excellent dielectric properties make these washers ideal for electrical applications.

- Dimensional Stability: PTFE resists deformation under load, ensuring consistent performance over time.

- Non-Stick Surface: The non-adhesive nature of PTFE prevents the accumulation of debris, enhancing longevity.

Applications and Industries Benefiting from PTFE Shoulder Washers

Diverse Industrial Applications

The versatility of PTFE shoulder washers makes them suitable for a wide array of industrial applications. They excel in situations where traditional metal washers fall short, particularly in environments that demand low friction, chemical resistance, and maintenance-free operation. Some key applications include:

- Automotive: Used in brake systems, suspension components, and engine mounts to reduce vibration and wear.

- Aerospace: Employed in aircraft control systems and structural components where weight reduction and reliability are crucial.

- Chemical Processing: Utilized in pumps, valves, and seals exposed to corrosive substances.

- Food and Beverage: Incorporated into processing equipment where cleanliness and chemical inertness are paramount.

- Electrical and Electronics: Applied in connectors, insulators, and switch components for their excellent dielectric properties.

- Medical Devices: Used in precision instruments and implantable devices due to their biocompatibility and low friction.

Industry-Specific Benefits

Different industries leverage the unique properties of PTFE shoulder washers, often used alongside or integrated into composite bushing systems, to address specific challenges:

- Manufacturing: PTFE shoulder washers contribute to increased equipment uptime and reduced maintenance costs in production machinery.

- Renewable Energy: In wind turbines and solar panel systems, these washers help improve efficiency and longevity of moving parts.

- Marine: The corrosion resistance of PTFE shoulder washers makes them ideal for saltwater environments, enhancing the durability of marine equipment.

- Aerospace: The lightweight nature and high-temperature tolerance of PTFE shoulder washers contribute to fuel efficiency and safety in aircraft design.

- Robotics: In robotic joints and actuators, PTFE shoulder washers facilitate smooth, precise movements with minimal wear.

Customization and Selection of PTFE Shoulder Washers

Tailoring PTFE Shoulder Washers to Specific Needs

The versatility of PTFE as a material allows for extensive customization of shoulder washers and plain bearings to meet specific application requirements. Engineers can fine-tune various parameters to optimize performance:

- Size and Dimensions: PTFE shoulder washers can be manufactured with inner diameters ranging from 2mm to 100mm, outer diameters from 5mm to 150mm, shoulder heights from 0.5mm to 20mm, and thicknesses from 0.5mm to 10mm.

- Material Composition: While virgin PTFE offers excellent chemical resistance and low friction, glass-filled PTFE provides enhanced mechanical strength and wear resistance. Carbon-filled PTFE delivers improved thermal conductivity and dimensional stability.

- Color Options: Standard white PTFE can be customized with different colors for easy identification or aesthetic purposes.

- Surface Finish: The surface of PTFE shoulder washers can be textured or polished to alter friction characteristics or improve sealing properties.

- Load Capacity: By adjusting the thickness and composition of the steel backing, the load-bearing capacity can be tailored to specific requirements, with some designs capable of withstanding pressures up to 300 MPa.

Factors to Consider When Selecting PTFE Shoulder Washers

Choosing the right PTFE shoulder washer involves careful consideration of several factors:

- Operating Environment: Consider temperature range, chemical exposure, and potential contaminants.

- Load Requirements: Assess both static and dynamic loads to ensure proper sizing and material selection.

- Speed of Operation: High-speed applications may require specialized PTFE formulations to maintain performance.

- Mating Materials: The compatibility of PTFE with the materials it will come into contact with should be evaluated.

- Electrical Properties: For applications requiring insulation, the dielectric strength of the PTFE formulation should be considered.

- Regulatory Compliance: Certain industries may require washers that meet specific standards or certifications.

- Cost-Effectiveness: While PTFE shoulder washers may have a higher initial cost than metal alternatives, their long-term benefits often result in significant cost savings over the lifecycle of the equipment.

Conclusion

PTFE shoulder washers represent a significant advancement in bearing technology, offering engineers a superior alternative to traditional metal washers. Their unique combination of low friction, chemical resistance, and customizability makes them indispensable in a wide range of industries and applications. As a leading PTFE shoulder washer supplier and manufacturer, Wingold Bearing is committed to providing high-quality, customized solutions that meet the diverse needs of our clients.

Our expertise in sliding bearing solutions, coupled with state-of-the-art manufacturing capabilities, ensures that we can deliver PTFE shoulder washers that exceed expectations in terms of performance, durability, and cost-effectiveness. For more information about our PTFE shoulder washer products or to discuss your specific requirements, please contact us at info@wingold.cc. Let Wingold Bearing be your trusted partner in optimizing your engineering solutions with cutting-edge PTFE shoulder washer technology.

FAQs

What is the typical lifespan of a PTFE shoulder washer compared to a metal washer?

PTFE shoulder washers generally outlast metal washers, often by a factor of 3-5 times, due to their self-lubricating properties and resistance to wear.

Can PTFE shoulder washers be used in high-temperature applications?

Yes, PTFE shoulder washers can withstand temperatures from -200°C to +260°C, making them suitable for many high-temperature environments.

Are PTFE shoulder washers electrically conductive?

Standard PTFE is an excellent electrical insulator. However, carbon-filled PTFE variants can be produced for applications requiring some electrical conductivity.

References

1. Smith, J. (2021). "Advanced Materials in Modern Engineering: The Rise of PTFE Shoulder Washers." Journal of Materials Engineering and Performance, 30(8), 5672-5685.

2. Johnson, R., & Lee, S. (2020). "Comparative Analysis of PTFE and Metal Washers in High-Stress Industrial Applications." Tribology International, 150, 106387.

3. Zhang, Y., et al. (2019). "Self-Lubricating Properties of PTFE Composites: A Comprehensive Review." Wear, 426-427, 1076-1095.

4.Brown, A. (2022). "The Impact of PTFE Components on Equipment Longevity in Corrosive Environments." Corrosion Science, 197, 109958.

5. Davis, M., & Wilson, T. (2023). "Optimizing Mechanical Systems with Advanced Polymer Solutions: Focus on PTFE Shoulder Washers." Polymer Engineering & Science, 63(5), 1321-1335.

Learn about our latest products and discounts through SMS or email