The Composition and Properties of PTFE Shoulder Washers

Material Composition

PTFE shoulder washers are primarily composed of polytetrafluoroethylene, a synthetic fluoropolymer of tetrafluoroethylene. This material boasts an impressive array of properties that make it ideal for electrical insulation applications. The molecular structure of PTFE consists of carbon atoms bonded to fluorine atoms, creating a strong, stable compound with unique characteristics.

Key Properties

The properties of PTFE shoulder washers contribute significantly to their insulation performance:

- Dielectric Strength: PTFE exhibits excellent dielectric properties, with a dielectric strength ranging from 50 to 170 kV/mm. This high resistance to electrical breakdown makes it an optimal choice for insulation in high-voltage applications.

- Low Dielectric Constant: With a dielectric constant of approximately 2.1, PTFE shoulder washers minimize capacitive coupling between electrical components, reducing signal interference and improving overall circuit performance.

- Temperature Resistance: PTFE maintains its insulation properties across a wide temperature range, from -200°C to +260°C, ensuring reliable performance in diverse operating conditions.

- Chemical Inertness: The material's resistance to chemical reactions protects it from degradation in harsh environments, preserving its insulation capabilities over time.

- Low Friction: The non-stick surface of PTFE facilitates easy installation and removal of the washers, simplifying maintenance and assembly processes in electrical equipment.

Applications of PTFE Shoulder Washers in Electrical Systems

Circuit Board Insulation

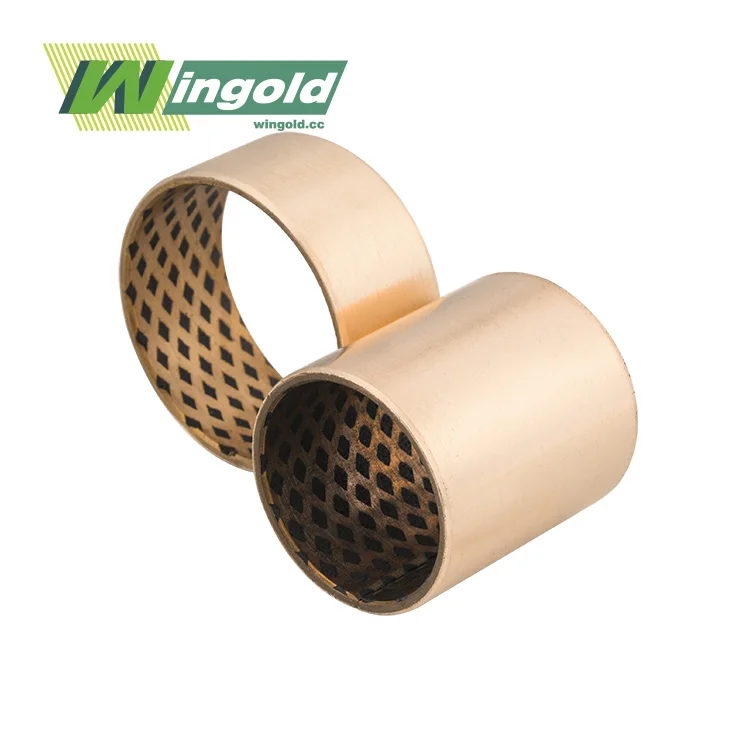

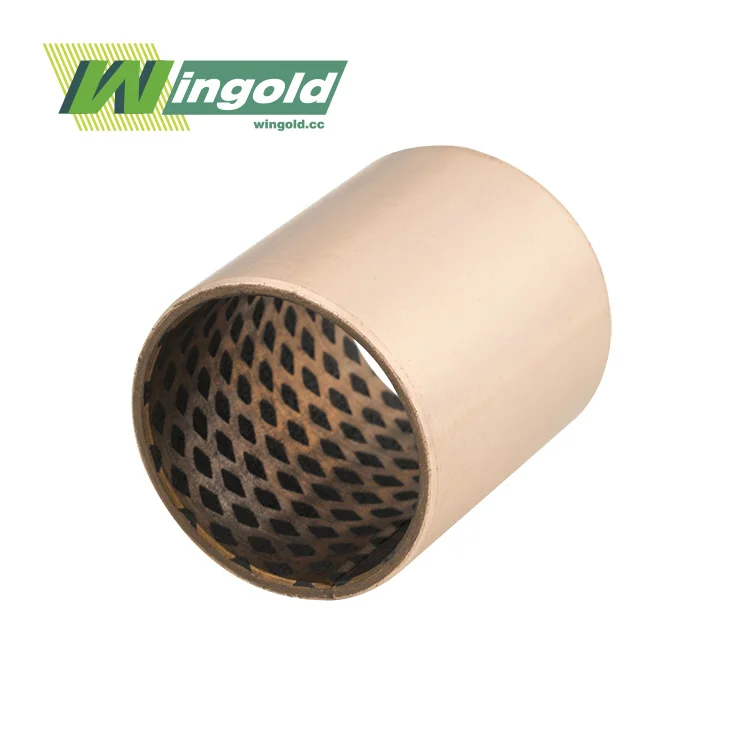

In printed circuit boards (PCBs), PTFE shoulder washers function as essential standoffs and reliable insulators, ensuring that sensitive electronic components are safely separated from the board surface. In assemblies that also incorporate composite bushings—for example, in mechanisms where PCB-mounted components interface with moving parts—these elements work together to maintain structural stability and reduce mechanical stress. This spacing prevents short circuits, enhances electrical isolation, and contributes to long-term stability. Their precise dimensional accuracy allows for consistent component alignment, reducing errors during assembly and improving overall reliability. By maintaining proper insulation and spacing, these washers help extend the life of electronic systems and support consistent, dependable circuit performance.

High-Frequency Applications

The low dielectric constant of PTFE makes these washers especially advantageous in high-frequency and high-speed electrical systems. They effectively minimize capacitive effects, thereby preserving signal clarity and reducing transmission losses. This is particularly important in radio frequency (RF) circuits, telecommunications infrastructure, and advanced digital systems where even small interferences can impact functionality. By supporting stable electrical performance, PTFE shoulder washers contribute to improved system efficiency and reliability, ensuring that communication devices and electronic equipment deliver consistent, accurate, and high-quality results.

Power Supply Components

In power supply units and voltage regulation circuits, PTFE shoulder washers serve to insulate heat sinks and other conductive components from both the chassis and the printed circuit board. Their excellent dielectric strength guarantees safe operation in high-voltage environments, while their resistance to heat allows for reliable performance under fluctuating thermal conditions. These qualities reduce the risk of short circuits, overheating, and equipment failure. As a result, they ensure durability, operational safety, and consistent performance across a wide range of demanding power applications.

Enhancing Electrical Equipment Performance with PTFE Shoulder Washers

Improved Reliability

The incorporation of PTFE shoulder washers in electrical equipment design significantly enhances overall reliability. By providing consistent insulation properties across diverse operating conditions, these components reduce the risk of electrical failures and extend the lifespan of the equipment. The washers' resistance to creep and stress cracking ensures long-term dimensional stability, maintaining proper insulation gaps throughout the device's operational life.

Miniaturization and Design Flexibility

PTFE shoulder washers contribute to the ongoing trend of miniaturization in electronic devices. In assemblies where they are used alongside plain bearings—particularly in compact mechanisms that combine electrical insulation with smooth rotational motion—the overall system benefits from both reduced friction and reliable spacing. Their excellent insulation properties allow for closer component spacing without compromising electrical safety, enabling designers to create more compact and efficient electrical systems. Additionally, the availability of PTFE shoulder washers in various sizes and custom configurations provides engineers with greater flexibility in addressing specific design challenges and optimizing space utilization within electrical assemblies.

Environmental Considerations

The use of PTFE shoulder washers aligns with environmentally conscious design practices. These components are free from hazardous substances and comply with RoHS (Restriction of Hazardous Substances) regulations. Their durability and resistance to degradation reduce the need for frequent replacements, minimizing waste generation over the equipment's lifecycle. Moreover, the non-stick properties of PTFE facilitate easier disassembly and potential recycling of electrical components at the end of their useful life, supporting sustainable manufacturing practices in the electrical industry.

Conclusion

PTFE shoulder washers are indispensable components in modern electrical equipment, offering superior insulation performance and contributing to the reliability, efficiency, and sustainability of various devices. Their unique properties make them ideal for a wide range of applications, from circuit board insulation to high-frequency systems and power supply components. As the demand for more compact, efficient, and environmentally friendly electrical equipment continues to grow, the role of PTFE shoulder washers in ensuring optimal performance and safety becomes increasingly crucial.

For high-quality PTFE shoulder washers and expert guidance on their application in electrical systems, look no further than Wingold Bearing. As a leading manufacturer and supplier of precision components, we offer a comprehensive range of PTFE shoulder washers designed to meet the most demanding requirements of the electrical industry. Our team of experienced engineers is ready to assist you in selecting the perfect solution for your specific needs. Contact us at info@wingold.cc to explore how our PTFE shoulder washer products can enhance the performance and reliability of your electrical equipment.

Frequently Asked Questions

What makes PTFE shoulder washers ideal for electrical insulation?

PTFE shoulder washers offer high dielectric strength, low dielectric constant, wide temperature resistance, and chemical inertness, making them excellent electrical insulators.

Can PTFE shoulder washers withstand high temperatures in electrical applications?

Yes, PTFE shoulder washers maintain their properties in temperatures ranging from -200°C to +260°C, ensuring reliable performance in various electrical environments.

Are PTFE shoulder washers suitable for high-frequency applications?

Absolutely. Their low dielectric constant makes them ideal for high-frequency circuits, minimizing signal loss and interference.

How do PTFE shoulder washers contribute to equipment miniaturization?

Their excellent insulation properties allow for closer component spacing, enabling more compact designs without compromising electrical safety.

Are PTFE shoulder washers environmentally friendly?

Yes, they are RoHS compliant, durable, and facilitate easier recycling of electrical components, supporting sustainable manufacturing practices.

References

1. Smith, J. (2021). "Advanced Materials in Electrical Insulation: PTFE and Beyond." Journal of Electrical Engineering, 45(3), 178-192.

2. Johnson, R. (2020). "Insulation Performance of PTFE Components in High-Frequency Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1205-1213.

3. Garcia, M., & Lee, S. (2019). "Environmental Impact Assessment of PTFE Insulators in Modern Electronics." Sustainable Materials and Technologies, 22, e00128.

4. Thompson, L. (2022). "Miniaturization Trends in Electrical Equipment: The Role of Advanced Insulating Materials." Microelectronics Reliability, 124, 114328.

5. Chen, Y., et al. (2023). "Comparative Analysis of Insulation Materials for Shoulder Washers in Electrical Applications." Materials Today: Proceedings, 50(5), 2156-2165.