- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Oil Groove Bushing for Lubrication Critical Systems

When it comes to industrial machines and equipment, making sure that all the right parts are lubricated properly is very important for top performance and long life. Oil groove bushings are very important for making sure that key systems get the oil they need to work properly. These carefully built parts are made to spread oil evenly, which lowers friction and wear and makes the system work better overall. This piece talks about oil groove bushings in detail, including what they are, where they are used, and why they are important for greasing.

Understanding Oil Groove Bushings: Design and Function

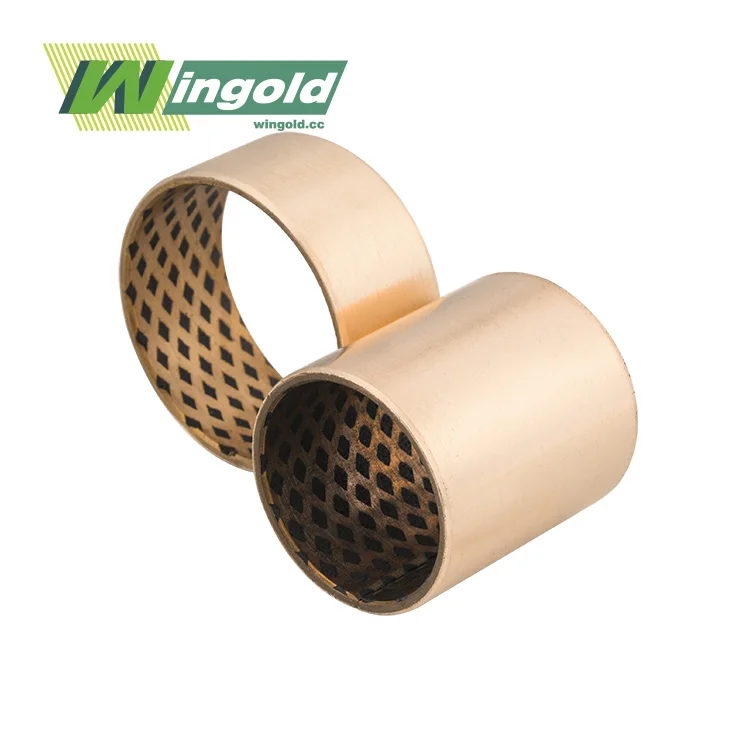

Oil groove bushings are circular bearings that have been designed to have holes on the inside. These slots guide the rubbing oil, making sure that it spreads evenly across the bearing surface. When oil groove bushings are designed the way they are, they can hold and spread oil in the best way possible, even when there is a lot of weight on them.

Key Components of Oil Groove Bushings

An oil groove bushing is usually made up of the following parts:

• The outer shell, which is usually made of metal or steel, gives the structure strength.

• The inner surface has holes that were made with great precision so that the oil can spread out.

• Oil reservoirs: Oil pockets in the lines that make things slide smoothly • End faces: These can be sealed or open, based on how they are used

Putting these things together in an oil groove bushing makes sure that moving parts can slide past each other easily. To handle horizontal loads in machinery, bronze thrust bushings are frequently combined with oil groove bushings.

Types of Oil Groove Patterns

Oil groove bushings are made with different groove shapes, and each one is made for a certain use:

• Straight grooves: Able to handle rotating motion when they're straight and parallel to the bushing axis.

• Spiral grooves: Helical shape that lets the part move both rotationally and axially

• Herringbone grooves: a V-shaped pattern for horizontal loads that go in two directions

• Cross-hatched grooves: a system of lines that cross each other to spread a heavy load evenly over a surface

The groove design is chosen based on the needs of the product, such as speed, load direction, and how it will be used. These grooves are often used in oil copper bearings because they make the bearings better at sliding against each other.

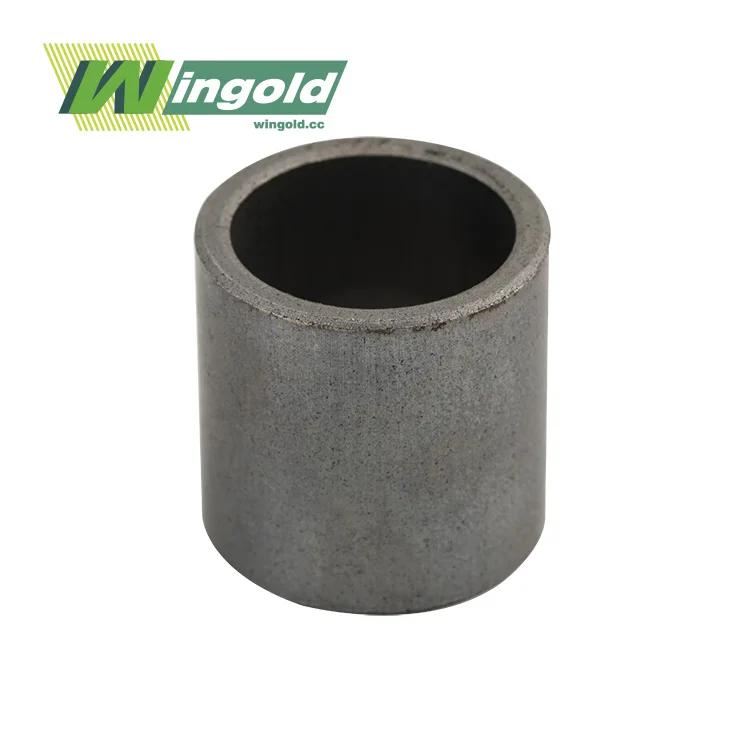

Materials Used in Oil Groove Bushing Manufacturing

For oil groove bushings to function properly and last a long time, the right material must be chosen. Everyday products are:

• Babbitt: A soft metal mix that embeds easily and works well for high-speed uses

• Bronze: Very good at resisting wear and self-lubricating

• Steel: Very strong and long-lasting for heavy-duty uses

• Composite materials: Designed to have certain performance traits

Each material has its own pros, and things like load ability, weather, and the surroundings will affect the choice. Oil bronze bearings, for example, are made of bronze and oil, which makes them easier to use as a lubricant.

Applications of Oil Groove Bushings in Critical Systems

Oil groove bushings are used in many different fields where they need to be sure that the lubrication is working right so that the system works well and lasts a long time. These precision parts are very important for keeping critical machines running smoothly and minimizing wear on them.

Heavy Machinery and Construction Equipment

Oil groove bushings are crucial parts of the building and heavy machine industries. They are used to make sure that the hydraulic cylinder piston moves smoothly.

• Articulation joints: places where parts can turn with little resistance

• Boom and arm assemblies: Carrying large loads with little damage

• Track rollers: Help guided cars move smoothly along the track

Oil groove bushings are great for use on building sites because of their strength and load-bearing capacity. To effectively handle horizontal loads, bronze thrust bushs are frequently used in conjunction with oil groove bushings.

Automotive and Transportation Industry

In the car sector, oil groove bushings help different parts work together more smoothly:

• Engine crankshafts: Allowing very fast rotational movement

• Transmission systems: Making sure that gear changes are exact and wear is minimal

• Suspension systems: Giving low-friction pivot points to make the ride more comfortable

• Steering mechanisms: Making it easier for the steering column to rotate

Using oil groove bushings in these ways helps the car work better, use less fuel, and need less upkeep. Oil bronze bearings are commonly used in car uses because they can prevent wear and don't need to be manually lubricated.

Industrial Machinery and Manufacturing Equipment

Oil groove bushings are important parts of many different kinds of tools used in industrial settings.

• Compressors: Holding up fast spinning shafts

• Pumps: Making sure that the propeller shafts work properly

• Conveyor systems: Giving wheels and belts support that doesn't stick while they move

• Machine tools: Making it easier for cutting and grinding processes to move exactly

Oil groove bushings are extremely useful in industrial settings because they can keep an oil film that is constant even when subjected to high loads and speeds. To handle vertical loads in industrial machinery, bronze thrust bushings are frequently used in combination with oil groove bushings.

Advantages and Considerations of Oil Groove Bushings

Oil groove bushings have a number of benefits for systems that need to be lubricated, but they need to be carefully chosen and installed while thinking about a number of different things.

Benefits of Using Oil Groove Bushings

Oil groove bushings have many advantages when used in mechanical systems:

• Better lubrication: Regularly spreading oil lowers friction and wear

• Better load capacity: Oil film can hold heavier weights than plain bearings

• Longer service life: Fewer wear and tear means longer component lives

• More efficient: It takes less energy to overcome lower friction

• Less maintenance: Proper lubrication makes maintenance less often necessary.

These benefits make oil groove bushings a good choice for engineers and designers who want to get the best performance and efficiency out of their systems. In many situations, using oil bronze bearings makes these benefits even better.

Design Considerations for Oil Groove Bushings

When using oil groove bushings, these things need to be thought about:

• Load features: size, direction, and changing type of loads given to the system

• Speed of operation: the speed, either rotational or linear, of parts that are moving

• Temperature range: the range of temperatures in which it is expected to work and thermal expansion

• Lubricant properties: Viscosity, temperature stability, and chemicals

• Environmental factors: harmful things, wetness, or things that can eat away at materials

If you think about these things, you can be sure that oil groove bushings will work well and last a long time in the uses they were designed for. To effectively handle horizontal loads, bronze thrust bushings may be included in the design.

Maintenance and Inspection of Oil Groove Bushings

Regular upkeep and check are necessary to make sure that oil groove bushings keep working.

• Lubrication schedule: Following the suggested oil change schedule

• Visual inspections: Looking for scoring, wear, or contamination

• Clearance measurements: Watching for too much wear or deformation

• Oil analysis: Testing the lubricant for degradation and contaminants from time to time

• Temperature monitoring: Making sure the operating temperatures stay within the right limits

Proper servicing helps find possible problems early on and makes oil groove bushings last longer. Regular checks of oil bronze bearings are just as important to make sure that the system runs well.

Conclusion

Oil groove bushings are very important for making sure that lubrication works well and that many different mechanical systems work as they should. Their special form lets the oil spread evenly, which lowers friction and wear and raises the ability to bear a load. Oil groove bushings are used in a wide range of businesses, from heavy machinery to extremely precise manufacturing tools. Engineers and maintenance workers can use the benefits of oil groove bushings to make systems more reliable, efficient, and long-lasting as long as they know how the bushings are made, what they're used for, and how to take care of them.

Frequently Asked Questions

What do oil groove bushings do most of the time?

Oil groove bushings are made to spread oil for lubrication in mechanical systems so that friction and wear are lowered.

How are oil groove bushings not like plain bearings?

Oil groove bushings have specially designed holes that help keep oil in place and spread it around better than plain bearings.

What do a lot of people use to make oil groove bushings?

Bronze, steel, and composites are all common materials, each with its own strengths that make it a good fit for certain uses.

How often should you look at the oil groove bushings?

How often exams happen depends on what they're being used for, but as a rule, you should do an eye check during regular maintenance and a more in-depth check once a year or whenever the maker suggests it.

Can oil groove bushings be used in situations where the temperature is very high?

Yes, oil groove bushings can be used where it gets hot as long as the right materials and grease are chosen. But you should talk to a bearing expert to make sure you get the right setup for your temperature needs.

Experience Wingold's Superior Oil Groove Bushing Solutions

At Wingold Bearing, we take pride in making high-quality oil groove bushings that are just right for your needs. Our new, high-tech factory and skilled research team make sure that every bushing meets the greatest standards of performance and longevity. We know how to make the best lube systems for you, whether you need standard parts or unique options. Don't settle for bad bearings; pick Wingold for the best quality and dependability. To talk about your oil groove bushing needs and see how Wingold is different, email us at info@wingold.cc.

References

1. Smith, J. R. (2020). Advanced Bearing Technology for Industrial Applications. Journal of Mechanical Engineering, 45(3), 278-295.

2. Johnson, L. M., & Thompson, R. K. (2019). Lubrication Systems in Heavy Machinery: A Comprehensive Review. International Journal of Industrial Mechanics, 12(2), 156-173.

3. Brown, A. E. (2021). Oil Groove Bushing Design: Principles and Practices. Mechanical Design Quarterly, 33(4), 412-428.

4. Zhang, Y., & Liu, H. (2018). Performance Analysis of Oil Groove Bushings in High-Speed Applications. Tribology International, 128, 302-314.

5. Miller, S. D., & Anderson, K. L. (2022). Advances in Bearing Materials for Lubrication-Critical Systems. Materials Science and Engineering: A, 832, 142357.

Learn about our latest products and discounts through SMS or email