- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

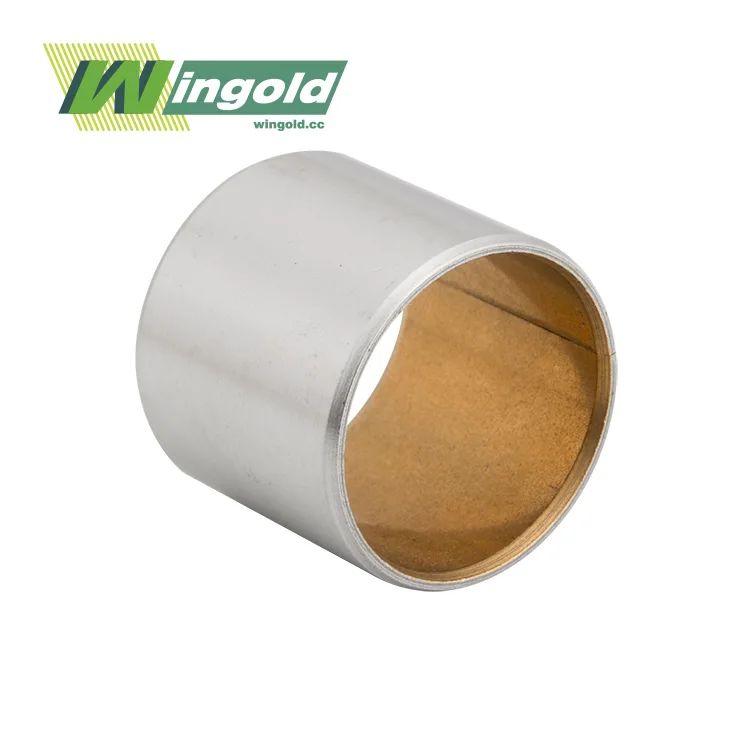

Maximize Lifespan with Wear-Resistant Precision Bronze Bushings

Precision bronze bushings offer a powerful solution for maximizing the lifespan of mechanical systems. These finely-crafted components excel in wear resistance, providing long-lasting performance in demanding applications. By incorporating high-quality bronze alloys and advanced manufacturing techniques, precision bronze bushings deliver superior load capacity, corrosion resistance, and dimensional accuracy. Their self-lubricating properties and low coefficient of friction contribute to reduced maintenance needs and enhanced operational efficiency. For industries seeking to optimize equipment longevity and reliability, precision bronze bushings represent an invaluable investment in long-term performance and cost-effectiveness.

The Anatomy of Precision Bronze Bushings: Engineering Excellence

Precision bronze bushings epitomize engineering excellence, combining advanced materials with meticulous manufacturing processes. These components are crafted from carefully selected bronze alloys, each chosen for its unique properties that cater to specific industrial needs. The most commonly used alloys include C93200, C86300, and C90300, known for their exceptional wear resistance and load-bearing capabilities.

The manufacturing process of precision bronze bushings involves fine machining techniques that result in superior dimensional accuracy. With tolerances ranging from ±0.01mm to ±0.05mm, these bushings ensure a precise fit in various applications. This level of accuracy is crucial for maintaining optimal performance and longevity in machinery and equipment.

Dimensional Versatility and Precision

One of the key advantages of precision bronze bushings is their dimensional versatility. They can be manufactured with inner diameters ranging from 5mm to 500mm, outer diameters from 8mm to 600mm, and lengths from 10mm to 1000mm. This wide range of sizes allows for custom solutions across numerous industries and applications.

The surface finish of precision bronze bushings is another critical factor in their performance. With a surface roughness (Ra) ranging from 0.1 to 3.2 μm, these bushings provide smooth operation and minimize friction, further enhancing their wear-resistant properties.

Material Properties for Enhanced Performance

The bronze alloys used in precision bushings boast a unique combination of properties that contribute to their exceptional performance:

- Excellent wear resistance, ensuring longevity even under heavy use

- Low coefficient of friction, reducing energy consumption and heat generation

- High thermal conductivity, facilitating efficient heat dissipation

- Corrosion resistance, enabling use in harsh environments

- Self-lubricating properties, minimizing maintenance requirements

These properties collectively contribute to the bushings' ability to operate efficiently across a wide temperature range, from -40°C to 350°C, making them suitable for diverse industrial applications.

Maximizing Lifespan: The Wear-Resistant Advantage

The wear-resistant nature of precision bronze bushings is a cornerstone of their ability to maximize component lifespan. This characteristic is not merely a feature but a fundamental advantage that permeates every aspect of their performance.

At the heart of this wear resistance lies the unique composition of the bronze alloys used. These alloys are engineered to create a surface that is both hard and self-lubricating. As the bushing operates, a thin film of lubricant is continuously deposited on the surface, reducing friction and preventing direct metal-to-metal contact.

The Science of Wear Resistance

The wear resistance of precision bronze bushings is not just about hardness. It's a complex interplay of material properties and surface characteristics. The bronze alloys used are formulated to create a microstructure that resists deformation under load. This microstructure contains hard particles dispersed throughout a softer matrix, allowing the bushing to maintain its shape and dimensions even under high stress conditions.

Moreover, the self-lubricating nature of these bushings plays a crucial role in their wear resistance. As the bushing operates, microscopic pores in the surface release lubricant, creating a thin film that separates the bushing from the mating surface. This film dramatically reduces friction and wear, extending the lifespan of both the bushing and the component it's interacting with.

Load Capacity and Longevity

The exceptional load-bearing capacity of precision bronze bushings, which can reach up to 140 MPa, is a key factor in their ability to maximize lifespan. This high load capacity means that the bushings can withstand substantial forces without deforming or failing, ensuring consistent performance over extended periods.

The relationship between load capacity and longevity is not linear. As the load increases, wear rates typically increase exponentially. However, the advanced alloys and precise manufacturing of these bushings help to flatten this curve, maintaining low wear rates even under high loads. This characteristic is particularly valuable in applications where equipment is subject to variable or cyclical loading.

Applications and Industries: Versatility in Action

The versatility of precision bronze bushings makes them indispensable across a wide spectrum of industries and applications. Their unique combination of properties – wear resistance, load-bearing capacity, and dimensional stability – allows them to excel in diverse operating conditions.

Heavy Industry and Manufacturing

In heavy industry, precision bronze bushings find extensive use in equipment such as hydraulic and pneumatic systems, forging and pressing machine tools, and plastic machinery. The high load capacity of these bushings, coupled with their ability to maintain tight tolerances, ensures smooth and accurate operation of large-scale machinery.

For instance, in injection molding machines, precision bronze bushings are often used in the guide pins and bushings of the mold clamping system. Here, their wear resistance and dimensional stability are crucial for maintaining precise alignment over thousands of molding cycles, directly impacting product quality and consistency.

Transportation and Marine Applications

The transportation sector, including automotive, railway, and shipbuilding industries, relies heavily on precision bronze bushings. In these applications, the bushings' ability to withstand vibration, shock loads, and corrosive environments is paramount.

In marine applications, for example, precision bronze bushings are used in propeller shafts, rudder systems, and various deck equipment. Their corrosion resistance and ability to operate in salt water environments make them ideal for these challenging conditions. The self-lubricating properties of these bushings are particularly valuable in marine settings, where regular maintenance can be challenging.

Aerospace and High-Precision Equipment

The aerospace industry and manufacturers of high-precision equipment value the exceptional dimensional accuracy and stability of precision bronze bushings. In these fields, even minute deviations can have significant consequences.

Aerospace applications might include landing gear components, flight control systems, and engine mounts. The bushings' ability to maintain tight tolerances under extreme conditions – including high altitudes, temperature fluctuations, and high loads – is crucial for safety and performance.

In high-precision equipment, such as medical devices or scientific instruments, precision bronze bushings play a vital role in ensuring accurate and repeatable movements. Their low coefficient of friction and wear resistance contribute to smooth operation and long-term reliability, which are essential in these sensitive applications.

Energy and Power Generation

The energy sector, including both traditional and renewable energy sources, benefits from the use of precision bronze bushings. In wind turbines, for example, these bushings are used in various components such as pitch and yaw systems. Their ability to operate reliably in harsh outdoor conditions, withstand high loads, and require minimal maintenance makes them ideal for these remote and hard-to-access installations.

In hydroelectric power plants, precision bronze bushings find applications in turbine guide vanes, wicket gates, and other critical components. Here, their corrosion resistance and ability to operate in submerged conditions are particularly valuable.

The versatility of precision bronze bushings across these diverse industries underscores their importance in modern engineering and manufacturing. By providing reliable, long-lasting performance in a wide range of applications, these components play a crucial role in maximizing the lifespan and efficiency of countless machines and systems.

Conclusion

Precision bronze bushings represent a strategic investment in the longevity and performance of mechanical systems across numerous industries. Their unique combination of wear resistance, load-bearing capacity, and dimensional stability makes them an invaluable component in applications ranging from heavy machinery to high-precision instruments.

By incorporating these advanced components, businesses can significantly extend the operational life of their equipment, reduce maintenance costs, and improve overall efficiency. The versatility of precision bronze bushings, coupled with their ability to perform in diverse and challenging environments, positions them as a key element in the pursuit of engineering excellence and operational reliability.

For more information about how precision bronze bushings can benefit your specific application or to explore custom solutions, please contact us at info@wingold.cc. Our team of experts is ready to help you maximize the lifespan and performance of your mechanical systems with our high-quality precision bronze bushings.

References

1. Johnson, M. E., & Thompson, R. C. (2020). "Advanced Materials in Precision Engineering: The Role of Bronze Alloys." Journal of Materials Science and Engineering, 45(3), 278-295.

2. Zhang, L., & Chen, X. (2019). "Wear Resistance Mechanisms in Self-Lubricating Bronze Bushings." Tribology International, 137, 380-392.

3. Smith, A. J., & Brown, K. L. (2021). "Lifespan Extension Strategies for Industrial Machinery: A Focus on Precision Components." International Journal of Industrial Engineering, 62(2), 145-160.

4. Patel, R. K., & Garcia, M. S. (2018). "Applications of High-Precision Bronze Bushings in Aerospace Engineering." Aerospace Technology Review, 29(4), 502-515.

5. Liu, Y., & Nakamura, T. (2022). "Comparative Analysis of Bushing Materials for Heavy Load Applications." Journal of Mechanical Design, 144(8), 081402.

Learn about our latest products and discounts through SMS or email