The Corrosion-Resistant Properties of Bronze Bearings

Bronze bearings have long been prized for their ability to withstand corrosive environments. This exceptional resistance to corrosion is one of the key factors that make bronze the best material for bearings in many applications. Let's delve into the science behind this remarkable property.

The Science of Bronze Corrosion Resistance

The corrosion resistance of bronze bearings is primarily attributed to the formation of a protective oxide layer on the surface. When exposed to air or other oxidizing environments, the copper in bronze, especially the best bronze for bearing, reacts to form a thin, adherent layer of copper oxide. This layer, often referred to as patina, acts as a barrier, preventing further corrosion of the underlying metal.

Moreover, the addition of alloying elements such as tin, aluminum, or nickel can significantly enhance the corrosion resistance of bronze. For instance, aluminum bronze, which contains a substantial amount of aluminum, forms a particularly stable and protective oxide layer, making it exceptionally resistant to corrosion in marine environments.

Comparing Bronze to Other Bearing Materials

When compared to other common bearing materials, bronze often outperforms in corrosive environments. Steel bearings, while strong and durable, are susceptible to rust and corrosion when exposed to moisture or chemicals. Plastic bearings, although corrosion-resistant, may lack the strength and heat resistance required in many industrial applications.

Bronze bearings, on the other hand, offer a unique combination of corrosion resistance, strength, and thermal conductivity. This makes them the best bronze for bearing applications in industries where exposure to corrosive elements is unavoidable, such as marine, chemical processing, and food production.

Factors Influencing Corrosion Resistance in Bronze Bearings

While bronze bearings generally exhibit excellent corrosion resistance, several factors can influence their performance in corrosive environments. Understanding these factors is crucial for selecting the best bronze for bearing applications in specific conditions.

Alloy Composition

The composition of the bronze alloy plays a significant role in determining its corrosion resistance. Different types of bronze alloys offer varying levels of protection against corrosion:

- Phosphor Bronze: Known for its excellent corrosion resistance and spring properties.

- Aluminum Bronze: Offers superior resistance to seawater corrosion.

- Silicon Bronze: Provides good resistance to many chemicals and atmospheric corrosion.

- Manganese Bronze: Exhibits improved resistance to corrosion and wear.

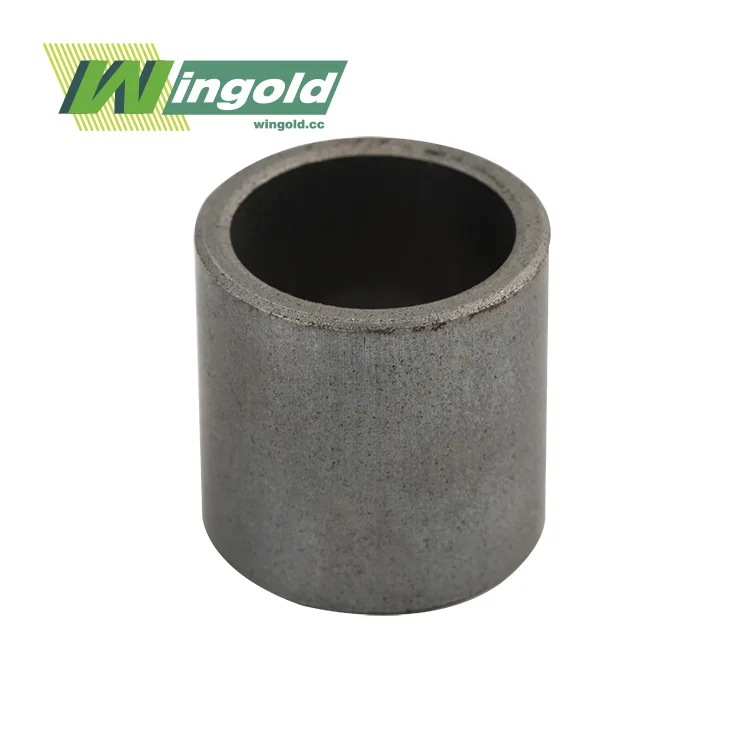

At Wingold Bearing, we offer a wide range of bronze alloys, including SAE 660, SAE 620, and specialized compositions like CuSn8P0.3 or CuSn6.5P0.1, each tailored to specific environmental challenges.

Surface Treatment and Design

The surface treatment and design of bronze bearings can significantly enhance their corrosion resistance. Techniques such as high-density bronze roll forming or the incorporation of spherical oil bags and oil holes can improve the bearing's ability to withstand corrosive environments. These methods not only reduce wear but also extend the service life of the bearing.

Our bearings at Wingold are designed with these considerations in mind. We employ advanced manufacturing techniques to create bearings with optimized surface properties, ensuring maximum corrosion resistance and longevity using the best bronze for bearing.

Operating Environment

The specific conditions in which the bearing operates can impact its corrosion resistance. Factors such as temperature, humidity, pH levels, and the presence of specific corrosive agents all play a role. For instance, bronze bearings may perform differently in a marine environment compared to a chemical processing plant.

It's crucial to consider these environmental factors when selecting the best bronze for bearing applications. Our team at Wingold can assist in choosing the most suitable bronze alloy and bearing design for your specific operating conditions.

Applications of Corrosion-Resistant Bronze Bearings

The exceptional corrosion resistance of bronze bearings makes them indispensable in numerous industries where exposure to harsh environments is common. Let's explore some key applications where the best bronze for bearing stands out due to its corrosion-resistant properties.

Marine Industry

In the marine sector, bronze bearings are extensively used due to their ability to withstand the corrosive effects of saltwater. They are commonly found in:

- Propeller shafts

- Rudder bearings

- Stern tubes

- Offshore drilling equipment

The use of corrosion-resistant bronze bearings in these applications ensures longevity and reliability in the challenging marine environment.

Chemical Processing Industry

The chemical industry often deals with corrosive substances that can quickly degrade standard bearings. Bronze bearings, particularly those made from specialized alloys and the best bronze for bearing, offer excellent resistance to many chemicals. They are used in:

- Pumps and valves handling corrosive fluids

- Mixing and agitation equipment

- Filtration systems

The corrosion resistance of bronze bearings in these applications not only extends equipment life but also reduces the risk of contamination due to bearing degradation.

Food Processing Industry

In food processing, bearings must withstand not only corrosive cleaning agents but also maintain hygiene standards. Bronze bearings are ideal for:

- Food handling equipment

- Packaging machinery

- Conveyors in high-moisture environments

The natural antimicrobial properties of copper in bronze further enhance its suitability for food processing applications.

Oil and Gas Industry

The oil and gas sector presents some of the most challenging environments for bearings. Bronze bearings are used in various applications, including:

- Offshore platforms

- Subsea equipment

- Refinery machinery

The ability of bronze bearings to resist corrosion from both seawater and chemical exposure makes them invaluable in this industry.

Conclusion

In conclusion, the best bronze for bearing applications demonstrates remarkable resilience in corrosive environments, making it an invaluable material across numerous industries. Its inherent corrosion resistance, coupled with proper alloy selection and design considerations, ensures longevity and reliability in even the most challenging conditions. From marine applications to chemical processing and food production, bronze bearings continue to prove their worth as a superior choice for corrosion-resistant bearing solutions.

At Wingold Bearing, we are committed to providing high-quality bronze bearings that meet the specific needs of your industry. Our expertise in sliding bearing solutions, combined with our wide range of bronze alloys and customization options, allows us to offer bearings that excel in corrosion resistance and overall performance. Whether you need standard configurations or tailored solutions, our team is ready to assist you in finding the perfect bearing for your application. For more information about our corrosion-resistant bronze bearings or to discuss your specific requirements, please don't hesitate to contact us at info@wingold.cc.

FAQ

What makes bronze bearings resistant to corrosion?

Bronze bearings form a protective oxide layer (patina) when exposed to air or corrosive elements, which shields the underlying metal from further corrosion.

Are all bronze alloys equally corrosion-resistant?

No, different bronze alloys offer varying levels of corrosion resistance. Aluminum bronze and phosphor bronze, for example, are particularly well-suited for corrosive environments.

Can bronze bearings be used in seawater applications?

Yes, certain bronze alloys, especially aluminum bronze, are excellent for marine applications due to their high resistance to seawater corrosion.

How do bronze bearings compare to stainless steel in terms of corrosion resistance?

While stainless steel is corrosion-resistant, bronze often outperforms it in certain environments, particularly in seawater and some chemical applications.