The Evolution of Bronze Bushings in Machinery

Historical Perspective on Bronze Bushings

Bronze bushings have been a foundation in apparatus plans for centuries. Their travel from fundamental, standardized components to exceedingly customized designing wonders is a confirmation of innovative advance. At first, bronze bushings were fundamentally utilized in straightforward mechanical frameworks, esteemed for their essential properties of toughness and smooth grinding. In any case, as apparatus got to be more complex and specialized, the impediments of one-size-fits-all bushings got to be clear.

Emergence of Customization in Bronze Bushing Design

The shift towards custom bronze bushings began as industries recognized the need for components tailored to specific applications. This evolution was driven by several factors:

- Increasing machinery complexity requiring specialized parts

- Growing demand for improved efficiency and performance

- Advancements in material science and manufacturing technologies

Current State of Custom Bronze Bushing Technology

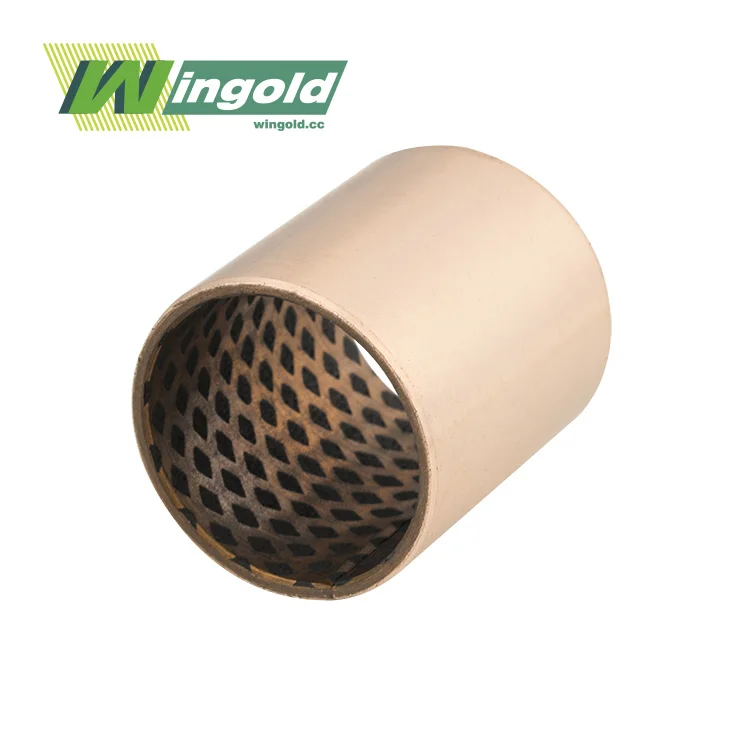

Today, custom bronze bushings represent a leap forward in machinery design. Modern manufacturing techniques, such as CNC machining and 3D printing, have expanded the possibilities for customization. Engineers can now design bushings with precise dimensions, unique alloy compositions, and specialized features like oil grooves and surface treatments. These advancements have made custom bronze bushings invaluable in industries ranging from automotive to aerospace, where performance and reliability are paramount.

Advantages of Custom Bronze Bushings in Modern Machinery

Enhanced Performance and Efficiency

Custom bronze bushings offer several performance advantages:

- Optimized load distribution and reduced friction

- Improved heat dissipation through tailored designs

- Enhanced lubrication properties with specialized oil grooves

Durability and Longevity

One of the key benefits of custom bronze bushings is their exceptional durability:

- Resistance to wear and corrosion

- Ability to withstand high loads and extreme conditions

- Longer service life compared to standard bushings

Cost-Effectiveness and ROI

While custom bronze bushings may have a higher initial cost compared to standard components, they offer substantial long-term cost benefits:

- Reduced frequency of replacements

- Lower maintenance and downtime costs

- Improved machinery performance leading to increased productivity

Applications and Future Trends in Custom Bronze Bushing Technology

Diverse Applications Across Industries

Custom bronze bushings find applications in a wide range of industries:

- Automotive: In engine components and suspension systems

- Aerospace: For landing gear and control surface mechanisms

- Heavy machinery: In construction and mining equipment

- Marine: For propeller shafts and rudder bearings

- Renewable energy: In wind turbine gearboxes and solar tracking systems

Emerging Technologies and Materials

The future of custom bronze bushings is closely tied to advancements in materials science and manufacturing technologies:

- Development of new bronze alloys with enhanced properties

- Integration of smart materials for self-monitoring capabilities

- Adoption of advanced manufacturing techniques like 3D printing for complex geometries

Sustainability and Environmental Considerations

As industries focus more on sustainability, custom bronze bushings are playing a role in creating more environmentally friendly machinery:

- Improved efficiency leading to reduced energy consumption

- Longer lifespan, reducing the need for replacements and waste

- Development of lead-free bronze alloys for environmental compliance

Conclusion

Custom bronze bushings are undoubtedly shaping the future of machinery design. Their ability to be tailored for specific applications, combined with their durability, performance advantages, and cost-effectiveness, makes them an integral part of modern engineering solutions. As industries continue to evolve and face new challenges, the role of custom bronze bushings in machinery design is likely to become even more significant. For those looking to leverage the benefits of custom bronze bushings in their machinery design, it's crucial to partner with experienced manufacturers who can provide tailored solutions. For more information on how custom bronze bushings can revolutionize your machinery design, contact us at info@wingold.cc.