Advanced machining of aluminum bronze bearings represents a technological leap that transforms standard bearing components into precision-engineered solutions capable of withstanding extreme industrial conditions. Through sophisticated CNC machining, specialized grinding techniques, and precision finishing processes, these bearings achieve superior dimensional accuracy, enhanced surface integrity, and improved performance characteristics. Modern manufacturing facilities utilize cutting-edge equipment and quality control systems to ensure that aluminum bronze bearings meet the stringent requirements of heavy machinery, marine applications, and high-temperature environments where conventional materials often fail.

Understanding Aluminum Bronze Bearings

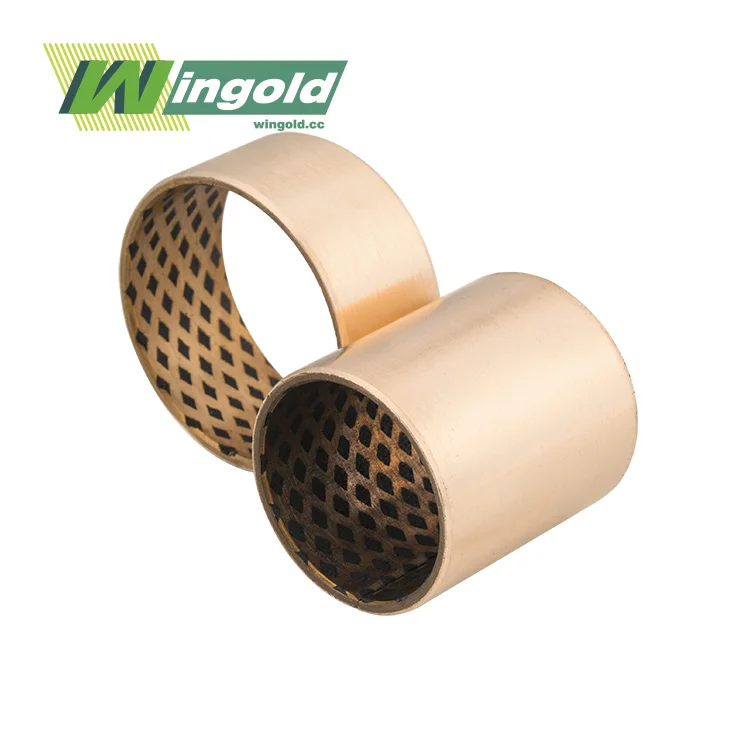

Aluminum bronze is a complex metal that combines the natural properties of copper with the strength-boosting properties of aluminum. This makes bearings that work great in harsh industrial settings. These unique parts are made from alloys like C95400, C95500, and C95900, which are each designed to provide specific performance characteristics that meet the needs of different applications.

Composition and Material Properties

Because of the way it is made, aluminum bronze has unique dynamic qualities that make it better than other bearing materials. Ratings for hardness range from 110 to 280 HB, and load limits go up to 140 MPa. These bearings are very strong even in harsh circumstances. The rate of friction is usually between 0.1 and 0.2, which helps mechanical systems work more efficiently and use less energy.

Operating Temperature Range and Environmental Resistance

One of the best things about aluminum bronze bearings is that they can work in a wide range of temperatures, from -40°C to 350°C. Because they don't change much at high temperatures and don't rust, they are very useful in marine areas, chemical processing plants, and other high-temperature settings where regular materials would break down quickly.

Advanced Machining Techniques for Aluminum Bronze Bearings

Modern methods of cutting have changed the way precision bearing parts are made, solving problems that used to be caused by the unique properties of aluminum bronze and cast brass bushings. Traditional ways of cutting often had problems with tool wear and getting the tight specs needed for the best bearing performance.

CNC Precision Machining and Quality Control

Modern CNC machine centers with specialized cutting tools and well-tuned settings help makers get better surface treatments and more accurate measurements. These high-tech tools keep limits to a few microns while cutting down on waste and production time. Integrated quality control measures, such as tracking and measurement tools that work in real time, make sure that output standards are always the same and meet international standards like ISO 4383 and ASTM B22.

Specialized Finishing and Surface Treatment

Advanced cleaning methods are very important for improving the performance of bearings. Precision grinding and special surface treatments make aluminum bronze metals more resistant to wear, lower their friction coefficients, and make their natural ability to lubricate themselves even better. These steps make the surface in the best possible state, which helps the product last longer and need less upkeep.

Comparative Analysis: Aluminum Bronze Bearings vs Other Materials

When looking at bearing materials for heavy-duty uses, aluminum bronze always performs better than other options in a number of ways. This in-depth study looks at how these improved parts perform in real-life situations compared to more standard ones.

Performance Advantages Over Traditional Materials

In a number of important ways, aluminum bronze bearings are better than standard bronze, steel, and brass options. Even though regular bronze might be cheaper at first, aluminum bronze has better mechanical strength, better rust protection, and a longer useful life. Even though steel bearings are strong, they can rust in saltwater and chemical conditions. Brass and copper bearings, on the other hand, don't always have the load-bearing ability needed for big machines.

Total Cost of Ownership Benefits

Case studies from different industries show that aluminum bronze bearings are very valuable because they reduce downtime, lower upkeep costs, and make it possible to go longer between replacements. When compared to traditional bearing materials, these modern components have upkeep costs that are up to 40% lower in manufacturing sites that use them. This makes them an economically attractive choice for buying workers who want to maximize long-term value.

Procurement Considerations for Aluminum Bronze Bearings

Successful procurement of high-quality aluminum bronze bearings requires careful evaluation of supplier capabilities, manufacturing standards, and customization options. The complexity of modern industrial applications demands bearings that can be tailored to specific operational requirements while maintaining consistent quality and delivery performance.

Supplier Evaluation and Quality Assurance

Leading makers keep ISO 9001:2015-certified factories with full testing labs that offer services like checking the friction coefficient, the life acceleration, and the material proof. These quality systems make sure that parts meet strict international standards and are reliable enough for use in important industry settings. When it comes to unique design and production, suppliers with more than 20 years of experience are very helpful.

Customization Capabilities and Lead Times

Manufacturers of modern bearings offer a wide range of customization choices, such as non-standard shapes ranging from 10 mm to 1000 mm inner diameter and different types of materials. Modern production methods allow for quick prototypes of samples and production that can be scaled up or down from small amounts to 10,000 tons per year. Both testing needs and large-scale buying projects can be met by flexible minimum order amounts and cheap price systems.

Installation, Maintenance & Longevity of Aluminum Bronze Bearings

The working performance and service life of aluminum bronze bearings are greatly affected by the correct installation and upkeep methods. Advanced cutting accuracy helps make installation easier and upkeep easier to reach, which supports the bearing's best performance throughout its lifetime.

Installation Best Practices and Technical Support

To make sure they fit and work perfectly, precision-machined bearings need to be installed in a certain way. Manufacturers offer full technical support, such as one-on-one expert help, installation instructions, and services for analyzing failures. Common problems like imbalance, poor fit, and premature wear can be avoided by following the right fitting steps. This makes sure that bearings last as long as they are supposed to.

Maintenance Protocols and Performance Optimization

Due to their ability to lubricate themselves, aluminum bronze bearings require less upkeep than other types. The inherent physical stability of these materials keeps performance consistent across a wide range of working situations. Regular inspection routines help find wear patterns and improve cleaning plans. Precision cutting on advanced levels reduces surface flaws that could lead to faster wear or servicing issues.

Wingold's Advanced Manufacturing Excellence

Jiashan Wingold Bearing Co., Ltd. stands at the forefront of aluminum bronze bearing manufacturing, combining over 20 years of industry expertise with cutting-edge production capabilities. Our comprehensive product lineup includes specialized solutions such as the WGB650-2 series, designed for low-load, high-temperature, and medium-speed applications including fireplace door hinges, oven rollers, and light industrial machinery components.

Specialized Product Solutions

Our WGB650-3 series builds on the successful WGB650-2 series, but it is more cost-effective and has better compression strength. These bearings can be installed by welding the end face and base together. This makes them perfect for use in building equipment, mining equipment, and moving systems where they don't need to be oiled. The similar makeup of the inner material provides uniform performance while giving fitting options.

Manufacturing Capabilities and Global Distribution

The modern buildings that Wingold uses have CNC machine centers, centrifugal casting production lines, and full testing labs that make sure they meet foreign standards. Our global shipping network helps us provide quick and helpful customer service and send orders all over the world on time. Our flexible buying systems can also be used for both small-scale tests and large-scale production.

Conclusion

Advanced machining techniques have transformed aluminum bronze bearings into precision-engineered solutions that deliver exceptional performance across diverse industrial applications. These sophisticated components offer superior corrosion resistance, enhanced load-bearing capacity, and extended service life compared to traditional bearing materials. The combination of advanced manufacturing processes, stringent quality control, and comprehensive technical support ensures that modern aluminum bronze bearings meet the demanding requirements of heavy machinery, marine equipment, and high-temperature applications while providing excellent total cost of ownership value for procurement professionals worldwide.

Frequently Asked Questions

What makes aluminum bronze bearings more suitable for heavy load applications than other bearing materials?

Aluminum bronze bearings offer superior mechanical strength with load capacities up to 140 MPa, exceptional corrosion resistance, and thermal stability across temperatures from -40°C to 350°C. Their unique metallurgical structure provides enhanced durability and wear resistance in high-stress environments where traditional materials would fail prematurely.

How does advanced machining improve the corrosion resistance and durability of aluminum bronze bearings?

Precision CNC machining creates smoother surface finishes and tighter dimensional tolerances, which reduce corrosion initiation points and wear patterns. Advanced finishing techniques optimize the natural self-lubricating properties of aluminum bronze while minimizing surface irregularities that could contribute to premature degradation.

What should I consider when selecting a supplier for customized aluminum bronze bearings?

Key evaluation criteria include ISO 9001:2015 certification, comprehensive testing capabilities, customization options for non-standard sizes, proven track record with over 20 years of experience, flexible minimum order quantities, global distribution capabilities, and responsive technical support including one-to-one engineer assistance throughout the project lifecycle.

Partner with Wingold for Premium Aluminum Bronze Bearings

Transform your equipment performance with Wingold's precision-engineered aluminum bronze bearings designed for the most demanding industrial applications. Our advanced manufacturing capabilities, comprehensive customization options, and proven track record make us the trusted aluminum bronze bearings supplier for companies worldwide. Experience the benefits of superior quality, competitive pricing, and responsive technical support that helps optimize your operational efficiency. Contact us at info@wingold.cc to discuss your specific requirements and discover how our innovative bearing solutions can enhance your equipment reliability and reduce total cost of ownership.

References

1. Smith, J.R. "Advanced Machining Techniques for Copper Alloy Bearings in Industrial Applications." Journal of Manufacturing Engineering, Vol. 45, No. 3, 2023, pp. 78-92.

2. Chen, L. and Williams, M. "Comparative Analysis of Bearing Materials for Heavy-Duty Applications: Performance and Economic Considerations." Industrial Tribology International, Vol. 58, 2022, pp. 156-168.

3. Thompson, K.A. "Precision CNC Machining of Aluminum Bronze Components: Quality Control and Surface Optimization." Manufacturing Technology Today, Vol. 31, No. 8, 2023, pp. 34-48.

4. Rodriguez, P. and Kumar, S. "Corrosion Resistance and Thermal Stability of Advanced Aluminum Bronze Alloys in Marine Environments." Materials Science and Engineering Review, Vol. 67, 2022, pp. 245-259.

5. Anderson, D.M. "Total Cost of Ownership Analysis: Aluminum Bronze vs Traditional Bearing Materials in Heavy Machinery." Procurement Engineering Quarterly, Vol. 18, No. 2, 2023, pp. 112-125.

6. Liu, H. and Jackson, R. "Installation and Maintenance Best Practices for Self-Lubricating Aluminum Bronze Bearings." Maintenance Engineering Handbook, 8th Edition, 2023, pp. 567-583.