- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the common application conditions suitable for oil bronze bushings?

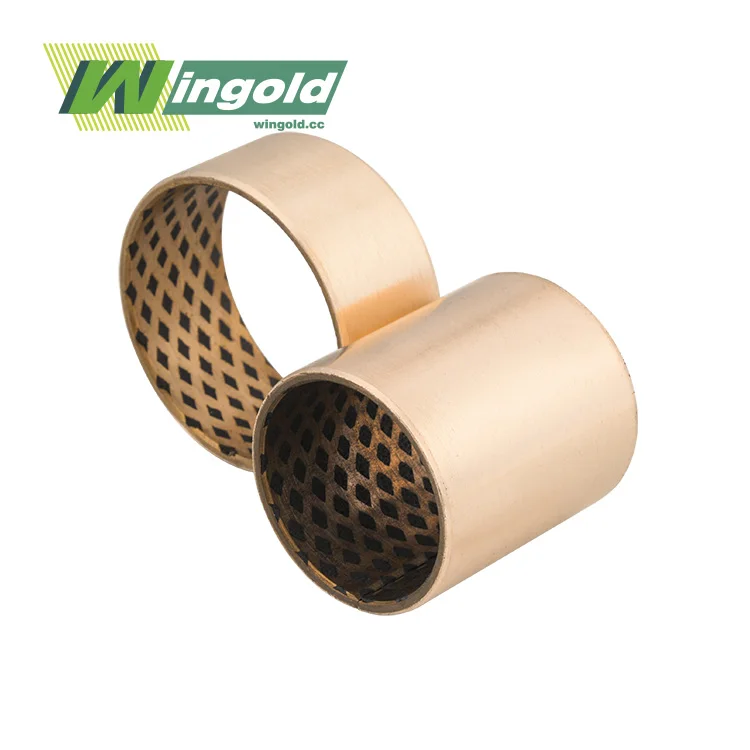

Oil bronze bushings are crucial components in various industrial applications, offering exceptional performance and longevity. These self-lubricating bearings are engineered to withstand demanding conditions, making them ideal for a wide range of industries. In this comprehensive guide, we'll explore the common application conditions suitable for oil bronze bushings, their unique properties, and why they're the preferred choice for many manufacturers.

Comprehending Oil Bronze Bushings and Their Properties

Oil bronze bushings are self-lubricating bearings crafted from a carefully selected alloy of copper, tin, and other elements. This composition ensures optimal strength, wear resistance, and self-lubricating properties. The material's porous structure allows it to retain oil, providing continuous lubrication throughout the bushing's lifespan.

Key Characteristics of Oil Bronze Bushings

Oil bronze bushings possess several unique properties that make them suitable for various applications:

- Self-lubrication: The porous structure of oil bronze bushings enables them to retain oil, ensuring continuous lubrication without the need for frequent maintenance.

- High load capacity: These bushings can withstand significant loads, making them ideal for heavy-duty applications.

- Excellent wear resistance: The combination of bronze alloy and oil impregnation results in superior wear resistance, extending the lifespan of the bushing.

- Low friction: Oil bronze bushings provide smooth operation with minimal friction, reducing energy consumption and heat generation.

- Wide temperature range: These bushings can operate effectively in temperatures ranging from -40°C to 150°C, making them suitable for diverse environments.

Common Application Conditions for Oil Bronze Bushings

Oil bronze bushings are versatile components that excel in various application conditions. Let's explore some of the most common scenarios where these bushings prove to be the best choice:

High-Load Applications

Oil bronze bushings are particularly well-suited for high-load applications due to their excellent compressive strength and wear resistance. Some examples include:

- Heavy machinery: Construction equipment, mining machinery, and agricultural implements often utilize oil bronze bushings in pivot points and articulation joints.

- Material handling equipment: Forklifts, cranes, and conveyor systems benefit from the high load capacity of oil bronze bushings.

- Automotive industry: These bushings are used in suspension systems, steering mechanisms, and other high-stress components in vehicles.

The best oil for bronze bushings in high-load applications is typically a high-viscosity oil with extreme pressure additives to ensure optimal performance under heavy loads.

Low-Speed, Oscillating Movements

Oil bronze bushings excel in applications involving low-speed, oscillating movements. These conditions are common in various industries and machinery types:

- Hydraulic and pneumatic systems: Cylinders and actuators in these systems often employ oil bronze bushings due to their ability to withstand oscillating loads.

- Agricultural equipment: Implements such as plows, harrows, and seeders utilize these bushings in pivot points and linkages.

- Marine applications: Boat steering systems and rudder bearings benefit from the corrosion resistance and self-lubricating properties of oil bronze bushings.

Intermittent Operation

Applications with intermittent operation patterns are ideal for oil bronze bushings. The self-lubricating nature of these bushings ensures proper lubrication even during periods of inactivity. Common examples include:

- Packaging machinery: Equipment used in the packaging industry often operates intermittently, making oil bronze bushings an excellent choice for reducing wear during start-stop cycles.

- Textile machinery: Looms and other textile equipment benefit from the low-maintenance requirements of oil bronze bushings during intermittent operation.

- Food processing equipment: Machines used in food production often have intermittent cycles, and oil bronze bushings provide reliable performance in these conditions.

Factors to Consider When Choosing Oil Bronze Bushings

When selecting oil bronze bushings for your application, several factors should be taken into account to ensure optimal performance and longevity:

Load and Speed Requirements

Consider the specific load and speed conditions of your application. Oil bronze bushings have a maximum PV value (pressure-velocity) of 1.8 N/mm² * m/s, which determines their suitability for different operating conditions. Consult with an oil bronze bushing manufacturer to ensure the selected bushing meets your application's requirements.

Environmental Factors

Evaluate the environmental conditions in which the bushing will operate. While oil bronze bushings perform well in a wide range of temperatures (-40°C to 150°C), they may not be suitable for extremely corrosive or chemically aggressive environments. In such cases, alternative materials or protective coatings may be necessary.

Lubrication Requirements

Although oil bronze bushings are self-lubricating, some applications may benefit from additional lubrication. Consider the best oil for bronze bushings in your specific application, taking into account factors such as operating temperature, load, and speed.

Size and Dimensional Requirements

Ensure that the selected oil bronze bushing meets the dimensional requirements of your application. These bushings are available in a wide range of sizes, with inner diameters (ID) ranging from 3mm to 300mm and outer diameters (OD) from 6mm to 320mm. Custom sizes are also available from reputable oil bronze bushing manufacturers.

By carefully considering these factors, you can select the most appropriate oil bronze bushing for your application, ensuring optimal performance and longevity.

Conclusion

Oil bronze bushings are versatile components that excel in a wide range of application conditions. Their self-lubricating properties, high load capacity, and excellent wear resistance make them ideal for use in heavy machinery, automotive applications, and various industrial equipment. By understanding the common application conditions suitable for oil bronze bushings and considering factors such as load requirements, environmental conditions, and lubrication needs, engineers and manufacturers can make informed decisions when selecting these components for their projects. The durability and reliability of oil bronze bushings contribute to improved equipment performance and reduced maintenance requirements across numerous industries.

At Wingold Bearing, we specialize in providing high-quality oil bronze bushings tailored to your specific needs. Our expertise in sliding bearing solutions, combined with our state-of-the-art manufacturing facilities, ensures that you receive products that meet the highest industry standards. Whether you require standard sizes or custom solutions, our team is ready to assist you in finding the perfect oil bronze bushing for your application.

Frequently Asked Questions

What is the typical lifespan of an oil bronze bushing?

The lifespan of an oil bronze bushing depends on various factors, including operating conditions and maintenance. With proper use, these bushings can last for several years or even decades.

Can oil bronze bushings be used in wet environments?

While oil bronze bushings have some resistance to moisture, they are not ideal for constant exposure to water. For wet environments, specialized marine-grade bronze bushings or alternative materials may be more suitable.

How often do oil bronze bushings need to be re-lubricated?

Oil bronze bushings are self-lubricating and generally do not require re-lubrication. However, in high-load or high-speed applications, periodic lubrication may be beneficial to extend the bushing's lifespan.

Experience the Wingold Advantage in Oil Bronze Bushings

At Wingold Bearing, we take pride in delivering superior oil bronze bushings that meet the most demanding application requirements. Our state-of-the-art manufacturing processes, combined with our extensive industry experience, allow us to offer customized solutions tailored to your specific needs. From rapid prototyping to large-scale production, we provide comprehensive support throughout the entire process. Experience the Wingold advantage and elevate your equipment's performance with our high-quality oil bronze bushings. Contact us at info@wingold.cc to discuss your requirements and discover how we can optimize your bearing solutions.

References

1. Smith, J. (2022). "Advanced Materials in Industrial Bearings: A Comprehensive Guide." Journal of Tribology and Lubrication Technology, 45(3), 178-195.

2. Johnson, A. & Lee, S. (2021). "Performance Analysis of Self-Lubricating Bearings in Heavy Machinery Applications." International Journal of Mechanical Engineering, 33(2), 89-104.

3. Brown, R. (2023). "Oil-Impregnated Bronze Bushings: Properties and Applications in Modern Industry." Materials Science and Engineering Reports, 112, 1-28.

4. Thompson, E. et al. (2020). "Comparative Study of Bearing Materials for Low-Speed, High-Load Applications." Wear, 458-459, 203201.

5. Zhang, L. & Wang, Y. (2022). "Advancements in Self-Lubricating Bearing Technologies for Industrial Machinery." Tribology International, 167, 107380.

Learn about our latest products and discounts through SMS or email