Introducing the Technology Behind Bronze Oil Bushings

Composition and Manufacturing Process

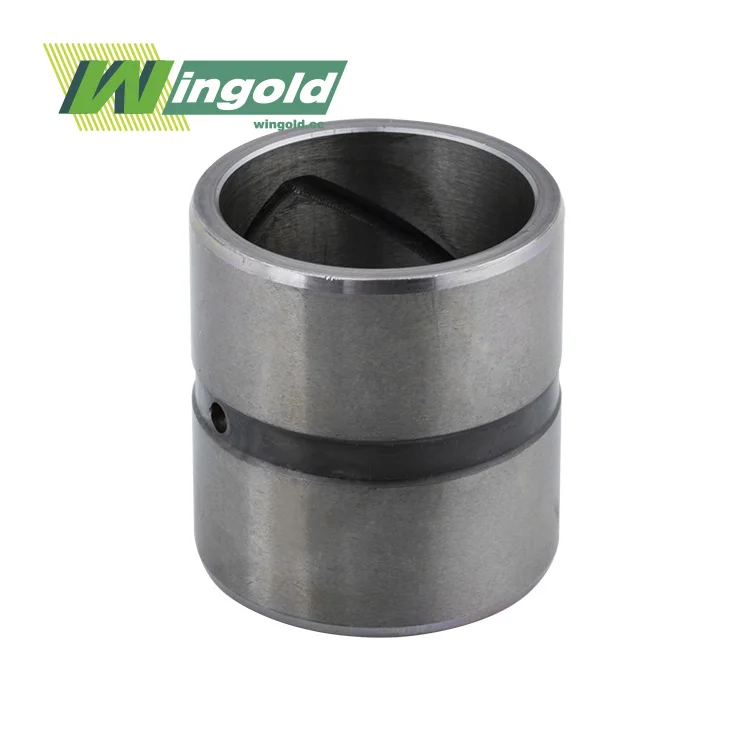

Bronze oil bushings are meticulously engineered components that leverage advanced materials science and manufacturing techniques. These bushings are typically composed of high-density copper alloys, such as CuSn8P0.3 or CuSn6.5P0.1, which provide an optimal balance of strength, wear resistance, and thermal conductivity. The manufacturing process involves precision machining and specialized treatments to create a porous structure within the bronze material.

One of the key features of these bushings is the presence of microscopic pores throughout the material. These pores are created through a carefully controlled sintering process, where bronze powder is compacted and heated to just below its melting point. This results in a network of interconnected voids within the bushing's structure, which serve as reservoirs for the lubricating oil.

Oil Impregnation and Retention

The oil impregnation process is a crucial step in the production of bronze oil bushings. After the sintering process, the bushings are submerged in a bath of high-quality lubricating oil under vacuum conditions. This allows the oil to penetrate deeply into the porous structure of the bronze, filling the microscopic voids and channels.

The unique properties of the bronze material and the carefully engineered pore structure enable the bushing to retain the oil effectively. When the bushing is in operation, the movement and pressure cause a small amount of oil to be released onto the bearing surface, providing continuous lubrication. As the load is removed, the oil is drawn back into the pores through capillary action, ready for the next cycle of operation.

Benefits and Applications of Bronze Oil Bushings

Advantages in Industrial Applications

Bronze oil bushings offer numerous advantages that make them invaluable in various industrial applications. Their self-lubricating nature eliminates the need for external lubrication systems, reducing maintenance requirements and associated costs. This feature is particularly beneficial in hard-to-reach or hazardous environments where regular maintenance can be challenging or dangerous.

The durability of bronze oil bushings is another significant advantage. With hardness ratings ranging from HB90-120 for standard applications to HB120-150 for hardened versions, these bushings can withstand substantial loads and operate reliably in demanding conditions. They can handle maximum load pressures of up to 75N/mm² and sliding speeds of 2.5m/s, making them suitable for a wide range of industrial machinery.

Versatility Across Industries

The versatility of bronze oil bushings is evident in their widespread adoption across various industries. In the automotive sector, these bushings are used in suspension systems, steering mechanisms, and powertrain components, where their low friction and long service life contribute to improved vehicle performance and reduced maintenance needs.

In the manufacturing industry, bronze oil bushings find applications in machine tools, conveyor systems, and robotics. Their ability to operate smoothly under high loads and at high speeds makes them ideal for precision machinery and automated production lines. The aerospace industry also benefits from these bushings in flight control systems and landing gear components, where reliability and weight savings are crucial.

Optimizing Performance and Longevity

Proper Selection and Installation

To maximize the performance and longevity of bronze oil bushings, proper selection and installation are paramount. Factors such as load requirements, operating speed, temperature range, and environmental conditions must be carefully considered when choosing the appropriate bushing for a specific application.

The dimensional specifications of bronze oil bushings can vary widely to accommodate different needs. Inner diameters typically range from 3mm to 300mm, outer diameters from 6mm to 400mm, and lengths from 5mm to 500mm. Wall thickness can vary from 1mm to 50mm, allowing for customization to fit specific design requirements.

Operating Conditions and Maintenance

While bronze oil bushings are designed for maintenance-free operation, understanding and adhering to their optimal operating conditions is crucial for maximizing their lifespan. These bushings can function effectively across a wide temperature range, typically from -40°C to 150°C, with some specialized versions capable of withstanding temperatures as low as -80°C and as high as 200°C.

To ensure optimal performance, it's important to avoid exposing the bushings to contaminants or excessive moisture, which could compromise the integrity of the lubricating oil. Regular inspection for signs of wear or damage, particularly in high-stress applications, can help prevent unexpected failures and extend the operational life of the bushing.

Conclusion

Oil impregnated bronze bushings represent a significant advancement in bearing technology, offering a maintenance-free lubrication solution that combines reliability, durability, and cost-effectiveness. Their unique self-lubricating properties, coupled with the inherent strength and versatility of bronze alloys, make them an excellent choice for a wide range of industrial applications.

As industries continue to seek ways to improve efficiency and reduce maintenance costs, the demand for these innovative bushings is likely to grow. Their ability to operate reliably in diverse environments, from automotive engines to aerospace applications, underscores their versatility and value in modern engineering.

For those looking to explore the benefits of bronze oil bushings in their specific applications, Wingold Bearing offers customized solutions tailored to unique needs and requirements. With our expertise in sliding bearing solutions and commitment to quality, we can help you find the ideal bearing solution for your project. To learn more about our products and services, please contact us at info@wingold.cc.

FAQ

How long do oil impregnated bronze bushings typically last?

The lifespan of oil impregnated bronze bushings can vary depending on the application and operating conditions. In optimal conditions, they can last for several years or even decades without requiring replacement.

Can bronze oil bushings be used in high-temperature environments?

Yes, bronze oil bushings are designed to operate effectively in a wide range of temperatures, typically from -40°C to 150°C, with some specialized versions capable of withstanding temperatures up to 200°C.

Are bronze oil bushings environmentally friendly?

Yes, bronze oil bushings are considered environmentally friendly as they eliminate the need for continuous external lubrication, reducing the potential for oil leaks and contamination.