The Evolution of Bearing Technology: From Traditional to Oilless Bronze Bushings

The evolution of bearing technology has been a long journey characterized by persistent innovation and refinement, ultimately leading to the emergence of oilless bronze bushings. In the past, traditional bearings depended heavily on frequent lubrication to maintain smooth functionality, a process that not only increased ongoing maintenance costs but also raised environmental concerns due to lubricant leakage and disposal issues. The development of oilless bronze bushings revolutionized this aspect by embedding solid lubricants directly into the bearing's structure. This breakthrough eliminated the reliance on external lubricants, paving the way for maintenance-free operation while improving reliability, efficiency, and environmental sustainability in industrial applications.

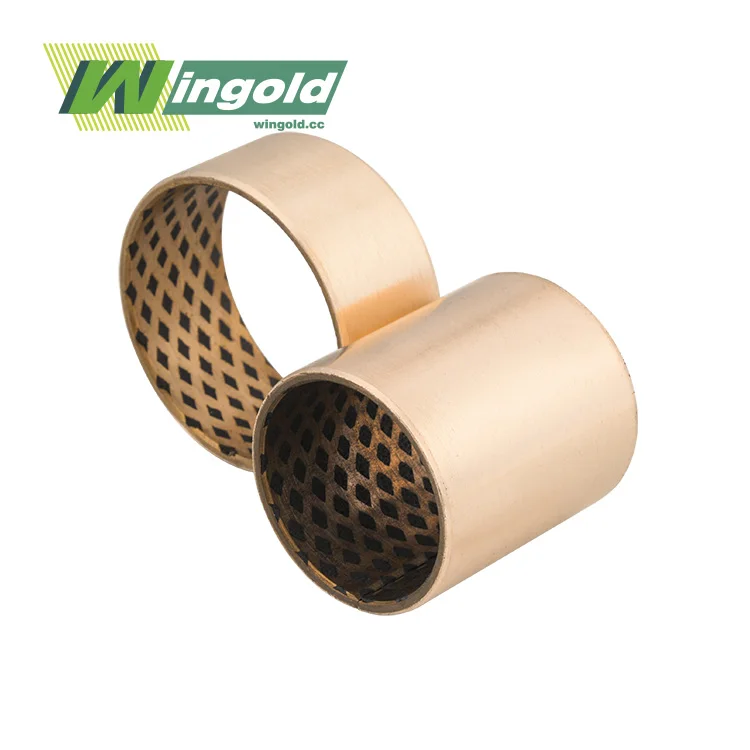

Oilless bronze bushings are meticulously manufactured from high-density copper alloy strips, chosen for their exceptional strength and durability. This robust base material is further enhanced through surface customization, where engineers can add diamond-shaped or hemispherical oil holes, along with strategically placed oil grooves, to meet specific operational requirements. Such precision design allows for optimized lubrication distribution from within the material itself, ensuring consistent performance over extended periods. This integrated approach results in a self-lubricating bearing that delivers superior wear resistance, load-bearing capacity, and operational stability, all without the need for external lubrication systems or frequent maintenance interventions.

Advantages of Oilless Bronze Bushings

The benefits of oilless bronze bushings are numerous and significant:

- High density and load-bearing capacity

- Excellent wear resistance

- Extended service life

- Reduced machine size and cost

- Environmentally friendly operation

These advantages have positioned oilless bronze bushings as a highly sought-after solution across a diverse range of industries where reliability, durability, and reduced maintenance are critical. In lifting machinery, they provide smooth and dependable operation under heavy loads, minimizing downtime and improving safety. Construction equipment benefits from their ability to withstand harsh environments and abrasive conditions without frequent servicing. In the automotive sector, they enhance performance and longevity while reducing lubrication-related costs. Machine tools gain from their precision and low-friction characteristics, improving efficiency and product quality. In mining machinery, their resilience to dust, impact, and extreme pressures ensures consistent performance even in the most demanding settings.

Impact of Oilless Bronze Bushings on Industrial Machinery Performance

The introduction of oilless bronze bushings has had a profound impact on the performance and reliability of industrial machinery. By removing the need for constant lubrication, these advanced components have significantly reduced maintenance frequency, allowing equipment to operate for longer periods without interruption. This not only lowers labor and material costs but also minimizes the risk of human error during lubrication processes. Additionally, the absence of external lubricants helps maintain a cleaner operating environment, which is crucial for sensitive applications such as food processing, pharmaceuticals, and electronics manufacturing. Overall, these bushings enhance productivity, extend machinery lifespan, and promote operational efficiency.

Enhanced Operational Efficiency

Oilless bronze bushings contribute to enhanced operational efficiency in several ways:

- Reduced downtime for maintenance

- Consistent performance under varying conditions

- Improved energy efficiency due to low friction

- Extended machinery lifespan

The self-lubricating properties of these bushings ensure smooth operation even in challenging environments, making them ideal for use in a wide range of industrial applications.

Cost Savings and Environmental Benefits

The adoption of oilless bronze bushings brings substantial cost-saving benefits to a wide range of industries. Since these components do not require regular lubrication, companies can greatly reduce the expenses associated with purchasing lubricants, maintaining lubrication systems, and performing routine servicing. This also minimizes the likelihood of costly unplanned downtime caused by bearing failures or lubrication-related issues. Furthermore, the absence of external lubricants keeps work areas cleaner, improving workplace safety and reducing cleanup costs. From an environmental perspective, it eliminates the risk of oil leakage or spills, supporting eco-friendly operations and helping industries comply with increasingly strict environmental regulations.

Applications and Future Prospects of Oilless Bronze Bushings

The versatility of oilless bronze bushings has led to their widespread adoption across various industries. These components have found applications in diverse machinery types, revolutionizing their performance and reliability.

Wide-ranging Industrial Applications

Oilless bronze bushings are utilized in numerous industrial sectors, including:

- Hydraulic and pneumatic systems

- Forging and pressing machine tools

- Plastic machinery

- Lifting and handling equipment

- Port machinery

- Office and fitness equipment

- Textile machinery

- Food processing equipment

- Chemical processing machinery

- Papermaking machinery

- Automotive industry

- Railway locomotives

- Shipbuilding industry

- Metallurgical machinery

- Engineering machinery

The adaptability of oilless bronze bushings to various forms—such as standard bearings, flanged sleeves, thrust washers, and ball bowls—greatly enhances their usability across diverse mechanical systems. This versatility allows engineers to select the most suitable configuration for specific load, motion, and installation requirements. Whether used in rotating shafts, axial load support, or complex joint mechanisms, these varied forms maintain the same self-lubricating efficiency and durability, ensuring reliable performance in a wide range of industrial and commercial applications.

Future Innovations and Trends

As technology continues to advance, the future of oilless bronze bushings looks promising. Ongoing research and development efforts are focused on further improving their performance characteristics, including:

- Enhanced load-bearing capacity

- Expanded temperature range tolerance

- Improved wear resistance

- Development of new alloy compositions

These advancements are expected to significantly broaden the application scope of oilless bronze bushings, enabling their integration into industries that have yet to fully realize their benefits. As performance characteristics improve—such as higher load capacity, better wear resistance, and greater temperature tolerance—these bushings could replace traditional bearings in more demanding environments. This potential shift may lead to transformative changes in sectors like aerospace, renewable energy, and advanced manufacturing, where reliability, efficiency, and reduced maintenance are critical for long-term operational success.

Conclusion

Oilless bronze bushings have undeniably revolutionized industrial machinery by offering a maintenance-free, high-performance solution for bearing applications. Their unique properties, including self-lubrication, high load-bearing capacity, and excellent wear resistance, have transformed the way industrial equipment operates. As industries continue to seek ways to improve efficiency, reduce costs, and minimize environmental impact, the role of oilless bronze bushings in industrial machinery is set to become even more pivotal.

For those looking to leverage the benefits of oilless bronze bushings in their industrial applications, Wingold Bearing offers a wide range of customized solutions. With our expertise in manufacturing high-quality bearings and commitment to innovation, we can help you optimize your machinery's performance and reliability. To learn more about our oilless bronze bushings and how they can benefit your specific application, please contact us at info@wingold.cc.

FAQs

What makes oilless bronze bushings different from traditional bearings?

Oilless bronze bushings incorporate solid lubricants within their material structure, eliminating the need for external lubrication and offering maintenance-free operation.

Can oilless bronze bushings withstand high temperatures?

Yes, many oilless bronze bushings can operate in temperatures ranging from -40°C to 280°C, making them suitable for various industrial applications.

Are oilless bronze bushings environmentally friendly?

Indeed, by eliminating the need for external lubricants, oilless bronze bushings contribute to a cleaner environment and reduce the risk of contamination.