The Science Behind Bronze Bushing Lubrication

Composition and Structure of Bronze Bushings

Bronze bushings are renowned for their exceptional mechanical properties and corrosion resistance. These components are typically crafted from copper alloys, with tin as the primary alloying element. The addition of tin to copper creates a material that combines strength, durability, and excellent thermal conductivity. The microstructure of bronze bushings is characterized by a dense, high-strength copper alloy base, which provides the foundation for their robust performance.

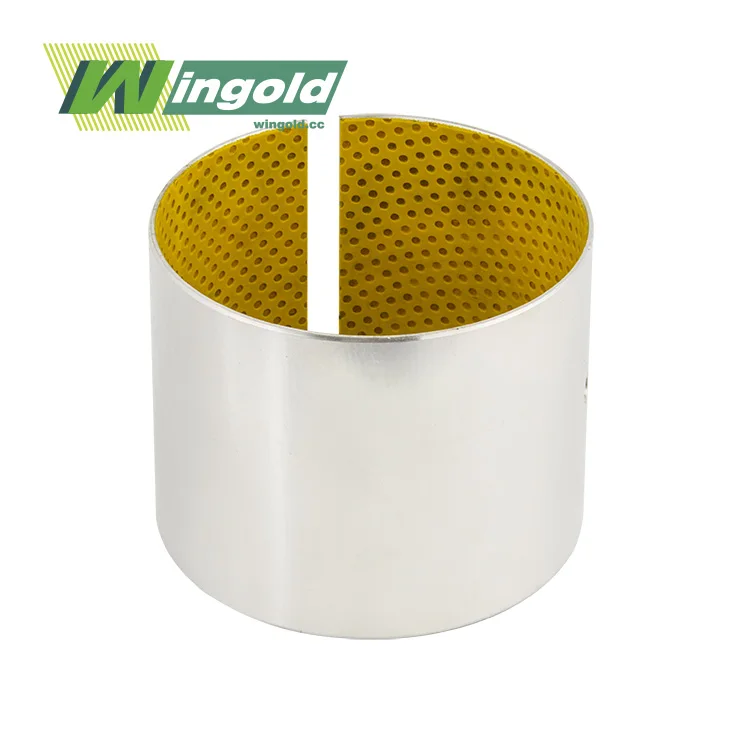

A key feature of modern bronze bushings is the presence of precisely engineered oil indentations. These indentations, which can be diamond-shaped or hemispherical, are strategically rolled into the bushing surface. This unique structural design plays a pivotal role in enhancing the self-lubricating properties of the bushing.

The Role of Lubricants in Bronze Bushings

The bronze bushing lubrication is a sophisticated process that leverages advanced materials science. High-performance lubricants, often synthetic in nature, are carefully selected for their compatibility with bronze and their ability to withstand extreme conditions. These lubricants typically boast a high viscosity index, often exceeding 140, which ensures they maintain their performance across a wide temperature range, from as low as -40°C to as high as 200°C.

The lubricant's primary function is to create a protective film on the bronze surface. This film acts as a barrier, significantly reducing friction between the bushing and the shaft it supports. The result is a dramatic decrease in wear and an extension of the bushing's operational life. Moreover, these advanced lubricants offer superior load-carrying capacity, making them ideal for high-pressure applications commonly encountered in industrial settings.

The Synergy of Structure and Lubrication

The magic of bronze bushing lubrication lies in the synergy between the bushing's structure and the applied lubricant. The oil indentations serve as microscopic reservoirs, holding the lubricant in place. As the bushing operates and experiences pressure and movement, these reservoirs release small amounts of lubricant onto the bearing surface.

This controlled release mechanism ensures a constant supply of lubricant exactly where it's needed, maintaining a thin but effective lubricating film even under challenging conditions. The process is self-regulating – higher loads or speeds trigger increased lubricant release, providing additional protection when it's most critical.

Advancements in Bronze Bushing Lubrication Technology

Innovative Lubricant Formulations

The field of bronze bushing lubrication has seen significant advancements in recent years, particularly in lubricant formulations. Modern lubricants are engineered to provide multifaceted protection. Beyond reducing friction, they offer exceptional corrosion resistance, crucial for preserving the integrity of bronze bushings in harsh or humid environments.

These advanced formulations also boast high oxidation stability, ensuring the lubricant maintains its effectiveness over extended periods. This property is particularly valuable in high-temperature applications or in situations where frequent maintenance is impractical. The result is extended service intervals, reducing downtime and maintenance costs for industrial operations.

Surface Engineering Techniques

Complementing the advancements in lubricant technology, surface engineering techniques have revolutionized the manufacturing of bronze bushings. Precision machining methods, such as CNC turning and milling, allow for the creation of intricate oil indentation patterns that optimize lubricant retention and distribution.

Moreover, innovative surface treatments can enhance the natural properties of bronze. Techniques like shot peening or burnishing can increase surface hardness and create a more uniform lubricant film in bronze bushing lubrication. These processes contribute to improved wear resistance and load-bearing capacity, further extending the lifespan of the bushing.

Integration of Smart Materials

The frontier of bronze bushing lubrication is exploring the integration of smart materials. These materials can respond to changes in temperature, pressure, or other environmental factors, adjusting their properties to optimize lubrication. For instance, some advanced bushings incorporate phase-change materials that can absorb excess heat, maintaining optimal operating temperatures and preserving lubricant integrity.

Another exciting development is the use of nanoparticle additives in lubricants. These microscopic particles can fill in surface irregularities at the molecular level, creating an even smoother operating surface. Some nanoparticles even have self-healing properties, helping to repair minor wear and tear as it occurs.

Optimizing Bronze Bushing Performance Through Enhanced Lubrication

Tailoring Lubrication Solutions for Specific Applications

The key to maximizing the performance of bronze bushings lies in tailoring the lubrication solution to the specific application. Factors such as load, speed, temperature, and environmental conditions all play crucial roles in determining the optimal lubrication strategy. For instance, high-load applications may require lubricants with extreme pressure additives, while those exposed to harsh chemicals might need specially formulated corrosion-resistant lubricants.

At Wingold Bearing, we specialize in creating customized lubrication solutions. Our team of experts analyzes the unique requirements of each application, considering factors like operating conditions, desired lifespan, and maintenance schedules. This bespoke approach ensures that each bronze bushing operates at peak efficiency, maximizing performance and longevity.

Implementing Proper Maintenance Protocols

While bronze bushings with enhanced lubrication properties require less maintenance than their traditional counterparts, implementing proper maintenance protocols in bronze bushing lubrication is still crucial for optimal performance. Regular inspections can help identify potential issues before they escalate, ensuring continuous smooth operation.

Maintenance procedures may include periodic re-lubrication, depending on the specific bushing design and operating conditions. However, with advanced self-lubricating bronze bushings, these intervals can be significantly extended. Some high-performance bushings may even operate maintenance-free for their entire lifespan in certain applications.

Monitoring and Predictive Maintenance

The future of bronze bushing lubrication lies in intelligent monitoring and predictive maintenance. Advanced sensor technologies can now be integrated into bushing systems to monitor key parameters such as temperature, vibration, and lubricant condition in real-time. This data can be analyzed to predict potential failures before they occur, allowing for proactive maintenance and minimizing unexpected downtime.

Furthermore, this continuous monitoring allows for the optimization of lubrication strategies over time. By analyzing performance data, engineers can fine-tune lubrication processes, potentially extending bushing life even further and improving overall system efficiency.

Conclusion

Bronze bushing lubrication is a complex yet fascinating field that continues to evolve, pushing the boundaries of what's possible in terms of performance, efficiency, and longevity. By leveraging advanced materials, innovative design techniques, and cutting-edge lubrication technologies, modern bronze bushings offer unparalleled reliability and durability across a wide range of industrial applications.

At Wingold Bearing, we're at the forefront of these advancements, continuously innovating to provide our customers with the best possible solutions. Whether you're looking for standard bronze bushings or need a custom solution for a challenging application, our team of experts is ready to assist you. For more information about our bronze bushing solutions and how they can benefit your operations, please contact us at info@wingold.cc.

FAQ

How often do self-lubricating bronze bushings need to be replaced?

The lifespan of self-lubricating bronze bushings varies depending on the application and operating conditions. In many cases, they can last for several years or even the entire lifetime of the equipment they're installed in.

Can bronze bushings with enhanced lubrication be used in high-temperature applications?

Yes, many advanced bronze bushing lubrication solutions are designed to withstand high temperatures, often up to 200°C or more, depending on the specific formulation.

Are these lubricants environmentally friendly?

Many modern lubricants used in bronze bushings are formulated with environmental considerations in mind, offering improved biodegradability and reduced toxicity compared to traditional lubricants.